Introduction

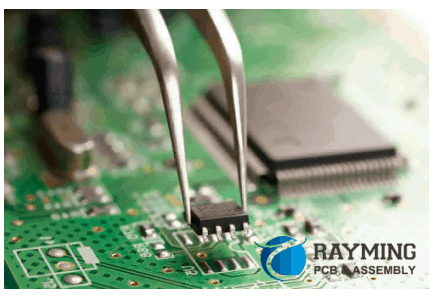

Surface mount technology (SMT) has become the standard assembly method for printed circuit boards due to higher component density, improved performance and lower costs compared to through-hole assembly. However, traditional high-volume SMT manufacturing typically requires large minimum order quantities that are not practical for prototyping needs.

Prototype SMT assembly enables low-volume PCB assembly for prototyping and small batch production. By utilizing specialized equipment and processes, prototype SMT assembly can deliver fully assembled boards in small quantities, allowing functional testing and design verification of new electronic designs.

This guide covers key considerations for low-volume prototype SMT assembly including capabilities, costs, quality factors and choosing an assembly partner.

Capabilities of Prototype SMT Assembly

Prototype SMT assembly providers utilize equipment and processes optimized for assembling PCBs in small batches rather than high volume production:

- Low Minimums – Ability to assemble small quantities like 1-10 boards

- Quick Turnaround – Fast assembly time in 1-4 days

- High Mix – Support for high component variety with rapid changeovers

- Flexible Lines – Manual and semi-automated processes for small volumes

- Design for Assembly Analysis – Checks to ensure manufacturability before assembly

Low Minimums

Prototype SMT assembly providers have minimal order quantity requirements, often starting from assembling just one board. This compares to production SMT lines that may require 500-1000+ boards to be cost effective.

Low minimums allow functional testing of designs with a small number of populated PCBs. For initial prototype runs, 1-3 assembled boards are common.

Quick Turnaround

Fast turnaround times of 24-72 hours enables rapid assembly of prototypes to quickly evaluate the design. For small batches of 5-10 boards, turnaround is generally 1-4 days depending upon complexity.

This compares favorably to typical production lead times of 2-4 weeks for SMT assembly in low volumes.

High Mix Support

Prototype volumes often have high component mix with limited quantities of each component type. SMT lines are optimized to support frequent changeovers between component types and feeders.

Flexible Setup

Manual assembly stations combined with semi-automated pick and place allow cost-effective assembly of low volumes. Built-in flexibility supports frequent product changeovers.

Design Analysis

Upfront DfM analysis done on the PCB design ensures components can be properly placed and soldered before assembly proceeds. This prevents issues and delays during the assembly process.

Cost Considerations for Prototype SMT Assembly

Prototype SMT assembly has higher per unit costs compared to volume production assembly. Key considerations for prototype assembly pricing:

- Setup/NRE Costs – Fixed costs for programming, stencils, setup. Spread over small quantities.

- Labor Intensive – Manual processes require more labor hours per board.

- Materials Overhead – Excess material from small, high mix orders.

- Yield Learning – Refine processes over initial iterations.

These factors will make prototype assembly 5-10X more expensive per board compared to production pricing. However, with total quantities in the 1-10 unit range, overall project cost can still be reasonable.

Ways to reduce prototype assembly costs:

- Use existing components in stock

- Standard packaging sizes

- Less component types

- Panelize boards for simultaneous assembly

- Loosen tolerance requirements

For higher volume prototyping, costs improve with order quantities ~25-100 units as NRE costs are amortized and processes optimized.

Quality Considerations

Prototype SMT assembly providers must balance speed and low cost with quality standards necessary for functional prototypes. Steps they utilize to ensure quality:

- Experienced Engineers – Skilled staff optimize processes for small batches

- Quality Processes -Utilize inspection, testing, and quality control at each step

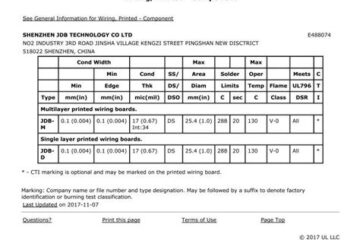

- IPC Standards – Assembly standards optimized for low volume

- Traceability – Component and board tracking for quality control

- Verification – Functional testing ensures boards operate properly

Although yields and performance may not equal high volume production, prototype SMT assembly still achieves quality suitable for design verification, testing, and early field trials.

Choosing A Prototype SMT Assembly Partner

Key factors to evaluate when selecting a prototype SMT assembly provider:

Proven Experience Preferably years of expertise specifically focused on low volume SMT assembly vs just being a production house.

Wide Component Selection Access to a large library of device packages and ability to support high component mix.

Design for Assembly Analysis Offering feedback on design to identify any issues before assembly is highly valuable.

Communication Clear documentation and project updates ensure smooth collaboration.

Quality Control Quality processes that are automated where possible; use of ESD control, inspection points, testing, etc.

Fast Turnaround Look for 1-4 day turnaround capability on small batches to enable rapid prototyping.

Cost Transparency Upfront pricing estimates; flexibility with minimum order quantities and low NRE costs.

One-stop Service PCBA providers who also offer PCB manufacturing simplify logistics if using the same company for both.

Scalability Partners who can seamlessly scale from low-mid volume prototypes to higher volume production.

Below are some recommended providers that specialize in offering quality prototype SMT assembly services:

Taiyo Assembly Services

- Location: China

- Minimum Qty: 1 board

- Lead Time: 24-48 hours

- Pricing: Low cost, starting from $80 per board

- Quality: IPC-A-610D certified

Taiyo focuses exclusively on fast turnaround, ultra low volume SMT assembly. Their prices are very competitive, especially for Asia.

WellPCB

- Location: China

- Minimum Qty: 5 boards

- Lead Time: 24 hours

- Pricing: Affordable, provides estimated costs

- Quality: IPC-A-610C, ISO 9001

WellPCB offers fast, low cost prototype assembly with the convenience of integrated PCB manufacturing.

Screaming Circuits

- Location: USA

- Minimum Qty: 1 board

- Lead Time: 3 days

- Pricing: Mid-range

- Quality: ITAR registered, ISO 9001

For lowest volumes and quality assembly with domestic USA production, Screaming Circuits is a proven choice.

Advance Assembly

- Location: USA

- Minimum Qty: 10 boards

- Lead Time: 4 days

- Pricing: Competitive for US-based

- Quality: ITAR, IPC Class 2 & 3

Advance Assembly provides reliable domestic assembly services scaled for low volume prototype builds.

Frequently Asked Questions

Here are some common questions about low volume prototype SMT assembly:

What are typical order quantities for prototype SMT assembly?

Prototype SMT assembly services support very low order quantities, even assembling just one board in some cases. Typical prototype order sizes are:

- 1-3 boards: Initial functional validation

- 5-10 boards: Design verification

- 10-25 boards: Field testing

Higher quantities of 25-100 boards help refine manufacturing processes and yield optimization.

How long does prototype SMT assembly take?

Lead times for fully assembling boards in small batches average 2-4 days. Some providers can assemble boards within 24 hours for the fastest possible prototyping. Simple boards may assemble faster while complex boards take longer.

This is much faster than the 2-4 week lead times typical of higher volume SMT production assembly.

Does prototype assembly support high component mix?

Yes, prototype SMT lines are designed to support high component mix and frequent product changeovers. While production SMT values high volume runs of single products for efficiency, prototype assembly is equipped for assembling small quantities of boards requiring many different components types.

How are yields for prototype SMT assembly?

Yields for prototype assembly may start lower, around 90-95% for initial builds as processes are refined and optimized over successive iterations. With sufficient volumes (~25+ units) and a robust design, yields can be improved to 95%+ which is acceptable for prototyping needs.

For comparison, mature production SMT assembly lines operate at very high yields exceeding 99%.

Is hand soldering required after SMT prototype assembly?

Some components like connectors or heat sinks may need to be hand soldered after the SMT process for fully assembled boards.

For quick-turn validation builds, full hand assembly can be a cost effective option for ultra-low quantities under 5 boards if SMT assembly is unavailable.

Are functional tests performed after prototype SMT assembly?

Reputable SMT assembly providers test prototype boards after assembly to validate basic functionality before delivery. This provides a level of assurance the assembly process was executed properly.

More comprehensive testing requires specialized test fixtures and equipment and is generally the customer’s responsibility during new product development.

Conclusion

Prototype SMT assembly fulfills the need for low volume PCB assembly for functional verification and testing early designs. With low minimums, fast turnaround and support for high component mixes, prototype SMT assembly allows for iteratively assembling, evaluating and improving a design prior to ramping up to production.

Partnering with an experienced provider who follows robust processes tailored for low quantities is key to getting high quality assembled prototypes cost and time efficiently. SMT assembly optimized for prototyping can accelerate the new product introduction process by rapidly progressing from design to prototype to production.

0 Comments