Introduction

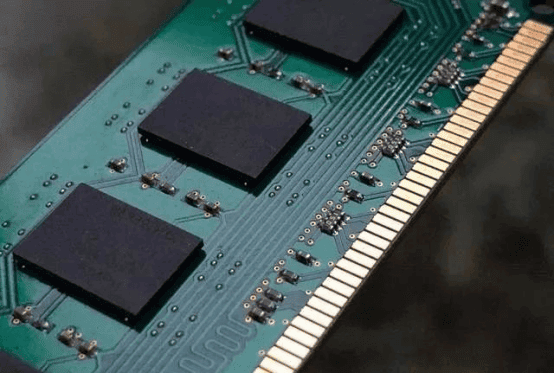

Printed circuit boards (PCBs) are an essential component of most modern electronic devices. They provide the physical platform to mount and connect various electronic components using conductive copper traces etched from copper sheets laminated onto a non-conductive substrate.

When you need custom designed PCBs manufactured, especially in low quantities for prototyping or small production runs, choosing the right PCB manufacturer is crucial to get good quality boards delivered on time and within budget.

This guide will cover factors to consider when selecting a low quantity PCB manufacturer, questions to ask potential manufacturers, and provide tips and recommendations for finding a PCB manufacturer that best fits your needs.

What Makes a Good Low Quantity PCB Manufacturer?

When looking for a low quantity PCB manufacturer suitable for prototyping or small scale production, there are a few key factors to evaluate:

Fast Turnaround Time

For low volume orders, you’ll want a manufacturer that can deliver finished boards quickly, usually within 1-2 weeks from receiving your Gerber design files. This enables rapid prototyping and testing of your board design.

Low Minimum Order Quantities

Many PCB manufacturers catering to higher volume production have minimum order quantities in the thousands. For low quantity orders, you’ll want minimal order quantities in the range of 5-10 boards.

Reasonable Pricing

Pricing is determined by the size and complexity of your board design. But quality low quantity manufacturers offer competitive pricing, some with instant online quotes. Be wary of dirt cheap boards that may cut corners on quality.

High Quality Standards

You want a manufacturer that adheres to stringent quality control standards for materials and processes, resulting in reliable PCBs built to your exact specifications. They should be ISO-9001 certified at a minimum.

Good Customer Service

Look for responsive customer service and technical support, in case you need assistance or have questions during the design and manufacturing process. Manufacturers located in your time zone can simplify communication.

Wide Range of Capabilities

The manufacturer should support a range of board sizes, layer counts, materials, finishes, etc. This gives you flexibility for current or future projects. Some even offer assembly services.

Production Transparency

Manufacturers that provide production status updates and are transparent about lead times give you peace of mind your order is on track.

Questions to Ask Potential Manufacturers

When evaluating low quantity PCB manufacturers, here are some key questions to ask:

What are your minimum order quantities and lead times?

This indicates if they are set up for true low quantity production. Lead times should be on the order of 1-2 weeks.

What design file formats do you accept?

Most will accept the standard Gerber format, but good to confirm. Other advanced formats like ODB++ speed up the design transfer process.

What board materials, finishes, and capabilities do you offer?

This includes number of layers, impedance control, HDI, etc. Make sure they can support the features you need.

Do you have design for manufacturing (DFM) checks?

Many will do DFM checks on your Gerber files to catch any errors before production. This prevents costly re-spins.

What quality and reliability testing is performed?

Look for IPC testing standards compliance for fabrication and assembly. Reliable manufacturers will share test data.

How transparent is your manufacturing process?

The more production visibility in terms of order tracking, status updates, and progress photos the better.

Do you offer assembly services?

Some low quantity manufacturers provide optional PCB assembly, which can be convenient for fully assembled prototypes.

What support channels do you offer customers?

This includes technical support resources, customer service availability, and responsiveness.

Recommended Low Quantity PCB Manufacturers

Based on factors like capabilities, quality, cost and reviews, here are some recommended low quantity PCB manufacturers to consider:

PCBWay

- Location: China

- Minimum Order: 5 boards

- Lead Time: 24 hours rush service available

- Capabilities: 12 layers, 4mil line/space, flex & rigid-flex PCBs

- Quality: ISO 9001:2015 & IATF 16949 certified

- Price: Instant online quotes & affordable standard pricing

PCBWay is one of the most well-known providers for low cost, high quality prototype and small batch PCB production. Their fast turnaround, excellent customer service and consistent quality makes them a top choice for low quantity PCB needs.

JLCPCB

- Location: China

- Minimum Order: 5 boards

- Lead Time: 2 days for basic boards

- Capabilities: 10 layers, 4mil line/space, SMT assembly

- Quality: ISO 9001 certified

- Price:Very low cost, starting at just $2 per board

JLCPCB has made low quantity PCB production extremely affordable. They have very low minimum order requirements and competitive pricing. Quality and reliability may not match more premium manufacturers.

PCB Cart

- Location: United States

- Minimum Order: none

- Lead Time: 11 days

- Capabilities: 12 layers, flex & rigid-flex PCBs

- Quality: ITAR registered, IPC 6012DS quality

- Price: Higher cost due to US manufacturing, instant quotes

For US-based production with shorter lead times, PCB Cart is a good low quantity PCB manufacturer choice. Their domestic manufacturing results in higher pricing but they have no minimum order and provide quality boards.

Eurocircuits

- Location: Europe

- Minimum Order: 1 board

- Lead Time: 15 days

- Capabilities: 16 layers, flex & HDI PCBs

- Quality: TS16949, UL, ISO 14001 certified

- Price: Mid-range pricing, free small order shipping

Eurocircuits manufacturers low quantity PCBs completely within Europe. They offer fast delivery for the European market. Their quality system and certifications ensures reliable board fabrication and assembly.

PCBCart

- Location: China

- Minimum Order: 5 boards

- Lead Time: 24 hours for rush orders

- Capabilities: Flex, rigid-flex, HDI and aluminum boards

- Quality: ISO 9001 certified

- Price: Low cost like other China manufacturers

PCBCart provides fast prototyping services alongside their production PCB manufacturing capabilities. Their quick-turn prototyping is ideal for getting boards in hand faster.

Frequently Asked Questions

Here are some common questions about low quantity PCB manufacturing:

How many PCBs constitute a low quantity order?

Low quantity PCB orders are typically 25 boards or less. The lowest quantities are for prototype boards, which can be as low as 1-5 boards from some manufacturers. Small scale production runs are usually around 10-25 boards.

What are the typical lead times for low quantity PCB orders?

For lowest quantities of just a few prototype boards, lead times can be as fast as 24-48 hours with rush or expedited service.

Standard lead times for small production batches are generally 1-2 weeks. For best results, allow 2-3 weeks from ordering to delivery so you can get your PCBs manufactured reliably without excessive rush charges.

Do low quantity PCBs cost more than higher volumes?

Yes, typically the cost per board decreases as order quantities increase above 100-200 boards. However, with some low quantity PCB manufacturers today, the pricing difference is not very significant for orders under 100 boards vs standard volumes of around 500 boards.

Advanced PCB technologies like HDI also reduce cost variances between low and higher quantities. So low quantity boards can be quite affordable.

Can I get assemby with low quantity PCB orders?

Some low quantity PCB manufacturers offer assembly services that allow you to get fully assembled boards, not just bare PCBs. This is most common in Asia, where labor rates are lower.

For ultra-low prototype quantities, hand assembly may be the only viable option. For orders around 10-25 boards, low-volume SMT assembly becomes affordable from select manufacturers.

How are low quantity PCBs suitable for prototyping?

Prototyping needs at least a small batch of boards to properly evaluate the design across multiple iterations. Issues like manufacturability, tolerances, and performance can only be verified with physical boards.

Low quantity prototyping goes through the full manufacturing processes while keeping costs low. This results in boards representative of eventual production quality.

Conclusion

For prototyping, proof-of-concept, and other low volume PCB manufacturing needs, partnering with the right low quantity PCB manufacturer is key. Factors like turnaround time, capabilities, quality, and cost allows you to get boards fabricated reliably and efficiently.

Leveraging the expertise of an experienced low quantity manufacturer optimize the process of transforming your electronic circuit idea into a physical PCB reality. They enable fast iteration by producing multiple versions of your board design with quick turnaround.

With today’s capabilities, even the smallest quantity PCB orders can deliver high quality boards. By asking the right questions and selecting a capable low quantity PCB manufacturing partner, your next project can get the specialized support it needs to produce a successful PCB in low volumes.

0 Comments