Introduction

Selecting the right printed circuit board (PCB) assembly manufacturer is crucial for bringing an electronics product to market. The PCB assembly process involves soldering surface-mount and through-hole components onto a printed circuit board. An experienced PCB assembly partner can ensure quality, reliability, and manufacturability of your boards. This guide provides tips on how to evaluate and select the ideal PCB assembly manufacturer for your needs.

Key Factors to Consider

When selecting a PCB assembly manufacturer, here are some of the most important factors to consider:

Manufacturing Capabilities

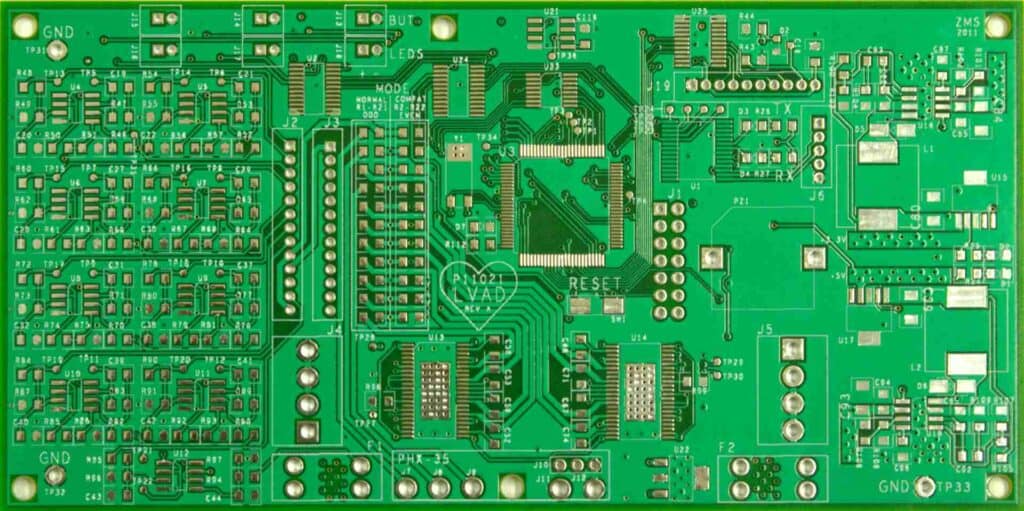

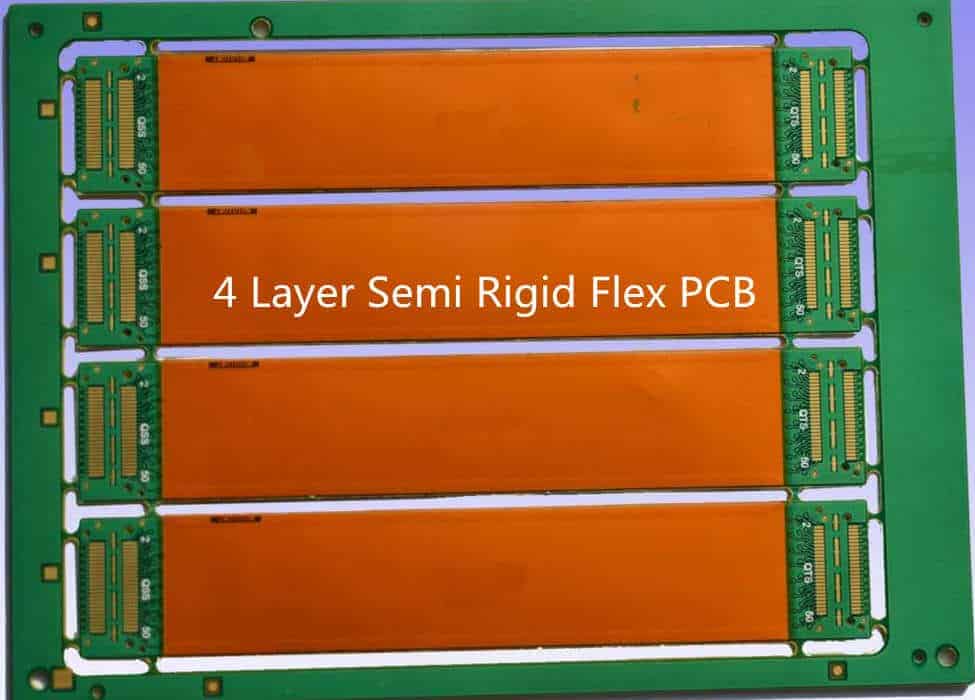

- Technology expertise – Look for expertise with the latest manufacturing technologies like SMT, through-hole, BGA, micro-BGA, and fine-pitch components. This ensures they can work with advanced PCB designs.

- Quality certifications – Leading manufacturers will have key certifications like ISO 9001, IATF 16949, or AS9100 demonstrating adherence to strict quality management systems.

- Range of assembly services – Seek partners that offer both SMT and through-hole assembly in-house for a streamlined, one-stop-shop experience. Also consider needs for other services like DFM analysis, test development, box build, and order fulfillment.

- Scalability – Choose a manufacturer capable of scaling up or down flexibly so they can meet your assembly needs at low and high production volumes.

- Lead time – Ask potential vendors about production lead times to ensure it aligns with your product launch needs and schedule.

PCB Design Capabilities

- DFM analysis – Manufacturers should offer design for manufacturing (DFM) services to evaluate your PCB designs for optimal manufacturability before going to production.

- Library services – To aid customers with component selection, the best manufacturers provide access to libraries of footprint data for 100,000+ components.

- Prototyping – For creating functioning PCB prototypes, look for in-house engineering, fabrication, and assembly services for fast turnaround.

Quality Processes

- Inspection – Rigorous inspection of PCBs at multiple stages using automated optical inspection (AOI) and x-ray can detect errors early.

- Testing – Functional testing of completed boards verifies proper performance and catches problems.

- Quality certifications – Certifications like ISO demonstrate the manufacturer’s commitment to continuous quality improvement.

- Traceability – A robust process for material tracking and version control helps ensure quality consistency across production runs.

Corporate Factors

- Technical expertise – Choose a partner with in-depth expertise in PCB fabrication and assembly to understand your product needs.

- Cost – Request quotes from multiple manufacturers to compare pricing. However, weigh cost against overall capabilities and quality.

- Customer service – The partner should assign an account manager for ongoing support plus have quick response times if any issues arise.

- Location – For supply chain simplicity, many prefer to work with domestic manufacturers for easier logistics and communication.

Top PCB Assembly Manufacturers

To give you a sense of leading PCB assembly manufacturers to consider, here is an overview of a few top companies:

Company 1: Foxconn

- Global electronics manufacturing giant

- Massive capacity for high-volume production

- Hundreds of facilities worldwide

- Excellent for large OEMs/ODMs shipping millions of units

Company 2: Jabil

- Multinational provider of manufacturing services

- Diverse capabilities from prototyping to volume assembly

- Facilities in Asia, Europe, and North America

- Ideal for startups to large enterprises

Company 3: Sanmina

- Leading EMS company focused on advanced technologies

- Extensive SMT assembly experience

- Sites across NA, Europe, and Asia

- Proven manufacturing partner for wide range of products

Company 4: US Circuits

- Veteran domestic PCB and assembly manufacturer

- ITAR-compliant facility with trusted supply chain

- Responsive prototyping through medium volumes

- Perfect for defense, aerospace, and medical

Company 5: Suntron

- Global provider of electronics manufacturing services

- Wide range of assembly capabilities and technologies

- Facilities in the Americas, Europe, and Asia

- Experience supporting full product lifecycle

This table summarizes some of the key differences between these major PCB assembly manufacturers:

| Company | Locations | Industries Served | Volume Capabilities | Certifications |

|---|---|---|---|---|

| Foxconn | Global | Consumer Electronics | High | ISO 9001, ISO 14001 |

| Jabil | Global | Diverse | Low to High | IATF 16949, AS9100 |

| Sanmina | Global | High-Tech/Communications | Medium to High | ISO 9001, ISO 14001 |

| US Circuits | USA | Defense/Aerospace/Medical | Low to Medium | ITAR, ISO 9001 |

| Suntron | Global | Broad Range | Low to High | ISO 9001, ISO 13485 |

Getting Started with a New Manufacturer

Once you’ve selected a PCB assembly manufacturer to partner with, here are some tips for getting started:

- Send detailed specifications – Provide complete design files, bill of materials, assembly drawings, product requirements, and quality expectations. This allows them to accurately quote and evaluate manufacturability.

- Request prototyping – Have the manufacturer build a small number of prototypes first to validate the design, process, and quality before committing to full production.

- Perform onsite audit – Tour the manufacturer’s facility to inspect their capabilities and processes firsthand and meet key team members.

- Define the relationship – Establish expectations upfront through an MSA or other agreement detailing pricing, IP protection, quality assurance, delivery terms, and communication plans.

- Allow time for ramp up – Recognize that it may take one or two iterations to optimize the assembly process and quality as both teams learn.

- Communicate frequently – Maintain ongoing contact with your assigned account manager via email, phone, and in-person visits for a transparent, productive partnership.

Conclusion

Choosing the right PCB assembly manufacturer and properly onboarding them sets the stage for a smooth product launch. Use this guide to understand the key assessment criteria, explore top manufacturers, and effectively engage with your chosen partner. With an experienced, proven assembly manufacturer at your side, you can bring your innovative electronics products from prototype to production efficiently and successfully.

Frequently Asked Questions

What are the differences between SMT and through-hole assembly?

SMT (surface mount technology) components are soldered directly onto the surface of the PCB without leads passing through holes. This enables smaller, more compact PCB designs. Through-hole components have wire leads that pass through holes in the board for soldering on the opposite side. Through-hole is an older, simpler assembly method still sometimes preferred for larger, higher power components.

Should I work with a local or offshore PCB assembly manufacturer?

Both models have pros and cons. Local manufacturers allow for easier communication and collaboration, quicker turnaround, and protection of IP. Offshore manufacturers in regions like China and Southeast Asia offer very low costs at high volumes but potentially longer lead times and greater risk of IP theft.

What types of testing do PCB assembly manufacturers perform?

Typical testing provided includes:

- In-circuit testing (ICT) to validate shorts, opens, misplaced parts

- Functional testing to confirm boards are working properly

- Burn-in testing on completed boards over an extended time under stress

- Environmental stress screening through temperature cycling and vibration

When should I engage a manufacturer for DFM analysis?

DFM (design for manufacturing) reviews should happen as early as possible, ideally when your design is about 70-80% complete. This allows the manufacturer to provide feedback on design changes to optimize manufacturing and avoid issues before you finalize the design files.

What documentation should I provide to a PCB assembly manufacturer?

To setup your project successfully, supply:

- Gerber and drill files for PCB fabrication

- Complete bill of materials with part numbers, values, and suppliers

- Approved vendor list for components

- Assembly drawings showing placement of all components

- Mechanical drawings for enclosure design

- Product specifications and testing requirements

- Any required qualification/validation documents

0 Comments