Introduction

For innovators and startups developing new electronics hardware, having a trusted partner for assembling small batches of printed circuit boards (PCBs) is invaluable. Small-run PCB assembly allows building prototypes quickly and economically when still refining a design.

This article will explore what capabilities to look for when selecting the best contract manufacturer for small-run PCB assembly requirements of 1-100 boards.

Capabilities Needed for Low Volume Assembly

An ideal partner for small assembly batches should offer the following key capabilities:

No minimums – Ability to assemble any quantity from just 1-5 boards for early prototyping.

Quick turnaround – Rapid assembly in 1-2 weeks to accelerate development.

Flexible component selection – Support for both through-hole and SMT parts in same board.

Hand assembly expertise – Skilled at precision hand-soldering and component mounting for small runs.

Engineering support – Provide guidance on design-for-assembly, part selection and troubleshooting.

Quality assurance – Perform testing and inspection even on low volumes to ensure quality.

Scalability – Ability to seamlessly scale up to higher volumes when design matures.

One-stop-shop – Offer both PCB fabrication and assembly for simplicity.

Key Small Run PCB Assembly Challenges

Some of the key challenges faced when dealing with low-volume PCB assembly are:

- Higher per unit costs due to setup overhead.

- Tedious hand assembly and soldering operations.

- Difficulty achieving consistency across small batches.

- Increased likelihood of production defects.

- Component sourcing logistics for low quantities.

- Lack of process automation and tooling.

An assembly partner experienced in small runs will have optimized processes to tackle these challenges.

On-Demand vs Batch Assembly Models

For small quantities, assembly services typically follow either an on-demand or a batched approach:

On-Demand

- Assemble boards as needed to meet immediate prototyping requirements.

- Suited for very low quantities.

- Provides maximum flexibility.

- Higher per unit cost.

Batch

- Group multiple assembly orders to process together.

- Cost effective when aggregating orders.

- Some delay to start while grouping each batch.

- Works well with consistent ongoing volumes.

Evaluate both models to choose the best fit based on your typical monthly or quarterly volumes.

Comparing Small Run Assembly Providers

Here is an overview of some of the reputed PCB assembly providers catering to small batch requirements:

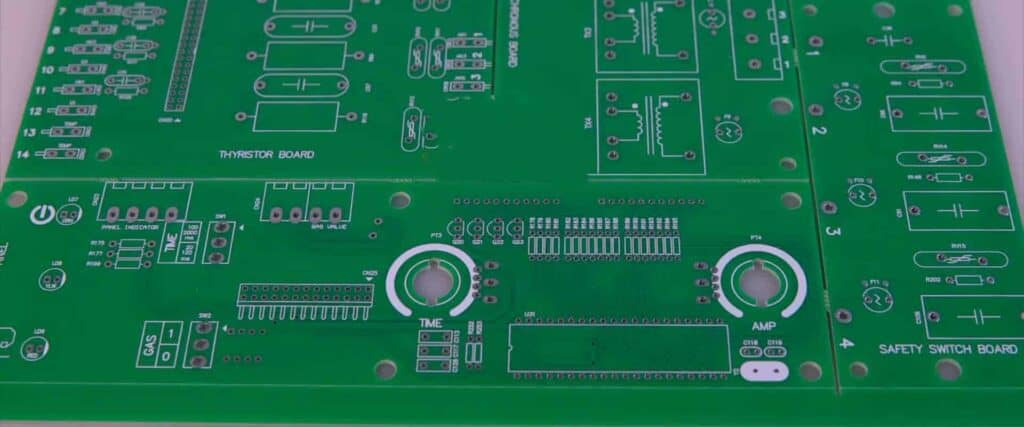

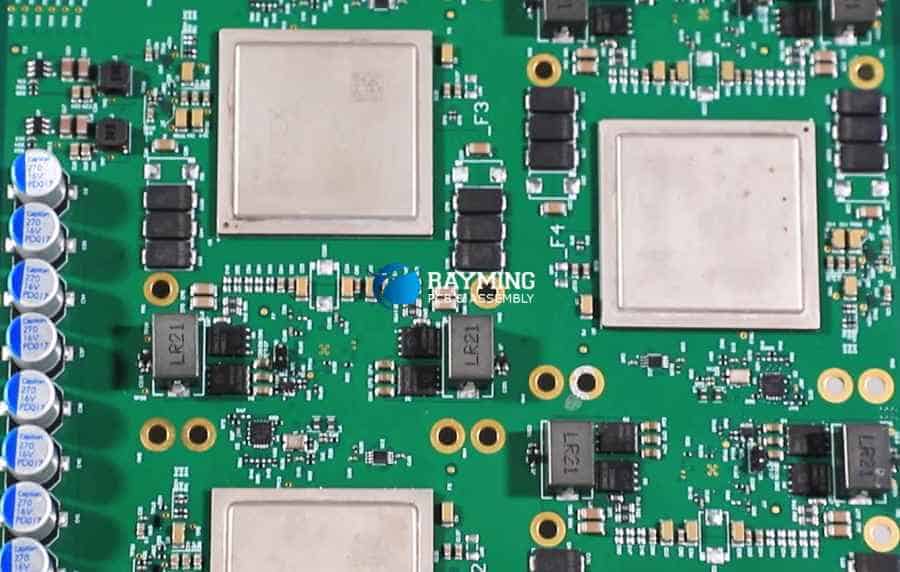

RAYMING PCB

- Starts at 5 boards quantity.

- Order online along with PCB fab for convenience.

- Low MOQ makes it suitable for first prototypes.

JLCPCB

- SMT assembly offered from just 10 boards.

- Known for budget pricing with bulk discounts.

- Wide range of assembly services.

WellPCB

- Mixed technology assembly combining SMT and through-hole.

- Small MOQs with online quoting.

- China-based with global shipping.

Screaming Circuits

- Specialized in super-quick turn prototype builds.

- Wide range of value-add testing services.

- US-based team of engineers.

This table summarizes some key differences:

| Company | Starting Qty | Location | Avg. Turnaround |

|---|---|---|---|

| RAYMING PCB & Assembly | 5 boards | China | 15 days |

| JLCPCB | 10 boards | China | 15 days |

| WellPCB | 1 board | China | 15 days |

| Screaming Circuits | 1 board | USA | 7-10 days |

Best Practices for Low Volume Assembly

Here are some best practices when embarking on small batch PCB assembly builds:

- Select components optimized for low volume assembly.

- Group multiple small quantity orders together where possible.

- Minimize BOM components to simplify assembly process.

- Budget for higher cost per board compared to high volumes.

- Plan adequate lead time for any long lead items.

- Review assembly partner’s work quality before committing large orders.

- Provide detailed test procedures to ensure quality.

- Build in test points for easy debugging of boards.

- Maintain close communication with assembly technicians during build.

Handling Upgrades from Prototype to Pilot Builds

As the design matures, you will need to upgrade from initial prototype builds to pre-production pilot builds:

- Gradually shift BOM from through-hole to more SMT components.

- Increase use of automated assembly processes.

- Introduce rigorous testing and inspection processes.

- Improve board-level traceability mechanisms.

- Freeze BOM and processes for consistent builds.

- Begin qualifying partners for eventual volume production needs.

The assembly partner should be able to support you through this evolution from low-volume prototyping to ramping up pre-production.

Frequently Asked Questions

What are typical lead times for small batch assembly?

For quantities under 10 boards, lead time is usually 10-15 days. Above 10 boards, lead time reduces to 5-10 days.

What are the typical per unit cost savings in high volumes?

As a rule of thumb, assembled PCB cost reduce by 50% when increasing from 10 boards to 100 boards.

Should I use off-shore or domestic assembly for small batches?

Off-shore partners are very cost competitive even for tiny volumes of just 5-10 boards. Domestic helps if you need 1-2 day turnaround.

Can assembly service providers also assist with component sourcing?

Yes, established assembly partners can procure components on your behalf based on your bill of materials. This simplifies logistics.

What testing is typically included in small batch assembly?

In-circuit testing and functional testing to verify assembly and basic board operation. Higher-level testing usually requires separate arrangements.

0 Comments