Introduction

For electronics engineers and designers, having the ability to rapidly prototype their printed circuit board (PCB) designs is invaluable for verifying concepts, testing functionality, and accelerating time-to-market. A fast turnaround on prototype PCB fabrication and assembly is often critical during product development cycles.

In this comprehensive guide, we will examine proven methods and tips to enable you to get your prototype boards produced and assembled in the fastest manner possible.

Key Factors for Fast PCB Prototypes

To enable fast turnaround of prototype PCBs, it is important to optimize the following aspects:

PCB Design – Create a design optimised for prototyping.

Fabrication Process – Choose the fastest fabrication options.

Assembly Process – Use methods suited for rapid assembly.

Components – Select components keeping speed in mind.

Partners – Choose suppliers capable of meeting tight schedules.

We will look at each of these factors in detail in the following sections.

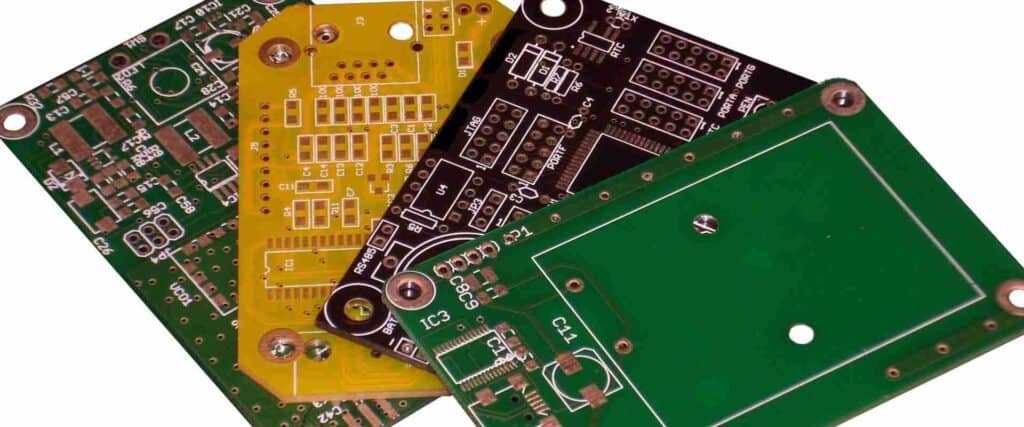

PCB Design Considerations for Fast Prototypes

The design of your PCB itself can have a significant impact on how quickly it can be prototyped. Here are some key design aspects to keep in mind:

- Avoid dense designs – Boards with too many tightly packed traces and components are harder to fabricate and assemble quickly. Allow some spacing.

- Minimize layer count – Stick to 2-layer boards if possible as they can be fabricated faster than multilayer boards.

- Avoid blind/buried vias – These special via structures slow down fabrication. Use only through-hole vias.

- Utilize design for manufacturability rules – Your PCB design tools likely have DFA/DFM rule checks. Run them to avoid any errors.

- Standardize frequently used sections – Create libraries of standard circuit sections like power, I/O, etc. that you reuse in multiple designs.

- Design with slots/cutouts – This allows panelizing multiple boards for batch assembly to speed up the assembly process.

PCB Fabrication Options for Fast Turnaround

For rapid fabrication of your prototype boards, utilize the following options:

- Choose fastest available turn time – Ask your fab about their fastest turnaround capability, often called 24-48 hour or 3-5 day options.

- Use quick-turn specials – Some fabs offer promotional quick-turn services a few times a year, often around major US & Asian holidays.

- Pool similar projects – If you have a few related boards to run, try fabricating them together.

- Avoid any unnecessary services – Skip any additional fabrication steps like controlled impedance, extra testing, stencil, etc.

- Choose regional fabrication – Use a fab located in your region to avoid long shipping times.

- Pay extra for rush service – Many fabs offer expedited service for a fee to move your job ahead in the queue.

Assembly Process for Fast Prototype PCBs

To complement the rapid PCB fabrication, you need to use assembly techniques focused on fast lead times:

- Use manual assembly – For very low quantities of 1-5 boards, hand assembly and soldering can be faster.

- Employ rapid SMT assembly – For batch quantities above 5 boards, fast SMT assembly lines are ideal for speed.

- Simplify the BOM – Reduce total component count and types to speed up assembly preparation.

- Minimize tantalum & electrolytic caps – These polar components slow down assembly pace.

- Utilize assembly slots/cutouts – Allows loading multiple boards onto a panel for simultaneous assembly.

- Perform post-assembly testing – Have the assembler do functional testing and ICT to reduce your post-delivery debugging time.

Component Selection Impact on Speed

The components you choose for your prototypes also affect how quickly they can be sourced and assembled:

- Leverage in-stock components – Favor distributor-stocked parts rather than long lead-time components.

- ** Reduce BOM line items** – Consolidate designs to use fewer unique component part numbers.

- Substitute hard-to-get parts – Swap any long lead components with suitable equivalents that are readily available.

- Use hand solderable packages – Opt for DIP ICs and through-hole connectors for manual assembly and mods during prototyping.

- Order samples in advance – For any long lead components, pre-order samples to have in-hand for your builds.

Choosing the Right Prototype Assembly Partner

To enable fast turnaround of your fully assembled boards, choose an assembly partner with proven capabilities suitable for prototypes:

- Specialization in prototypes – Select a service provider focused on prototype builds.

- Short turnaround times – Partner with a shop offering 1-2 week standard turn times.

- On-demand component sourcing – Shop that can quickly procure components on-demand to start builds faster.

- No minimum order quantity – Work with a shop that will assemble any quantity, even single boards.

- Production capabilities – Partner having both prototyping and volume production capabilities gives future flexibility.

Summary of Best Practices

To summarize, here are the best practices to get your prototype PCB boards in the fastest manner possible:

- Simplify the circuit design without compromising key functionality.

- Choose bare board fabrication options focused on speed.

- Employ rapid SMT assembly process along with quick component selection.

- Carefully select capable prototyping partners.

- Pay extra for expedited fabrication and assembly if required.

- Submit multiple related builds together.

- Plan designs in advance to avoid unnecessary revisions.

Frequently Asked Questions

How many days can I reduce turnaround time with expedited services?

Paying extra fees for expedited fabrication and assembly can shave off 5-10 days typically.

Is it feasible to get working boards delivered in one week?

For simple 2-4 layer boards with standard components, 1-week delivery is achievable with expedited services.

Should I expect any rise in costs for faster turnaround?

Yes, expedited fabs and assembly typically cost 20-50% more than normal services for accelerated delivery.

How can I get PCB fabrication quotes focused on fast turnaround?

Contact your preferred fabs directly and request their fastest turn time quotes for your specific build.

What are the lead times for stencil and PCB fabrication?

On average, stencil fabrication takes 1-3 days, PCB fabrication takes 3-5 days, and assembly adds another 3-5 days.

0 Comments