In the world of electronics, the process of transforming an idea into a functional device often begins with the creation of a PCB (Printed Circuit Board) prototype. A PCB prototype is a preliminary version of the final PCB design, used for testing, evaluation, and refinement before moving into full-scale production. Prototyping is an essential step in the development cycle, allowing engineers and designers to validate their designs, identify potential issues, and make necessary modifications before committing to large-scale manufacturing.

This comprehensive guide will walk you through the step-by-step process of creating a PCB prototype, covering everything from design to fabrication and assembly. Whether you’re a hobbyist, an entrepreneur, or an engineer working on a new product, this article will provide you with the knowledge and insights needed to navigate the prototyping process successfully.

Understanding the Importance of PCB Prototyping

Before delving into the prototyping process, it’s crucial to understand the importance of PCB prototyping and its role in the overall product development cycle. Here are some key benefits of creating a PCB prototype:

- Design Validation: Prototyping allows you to validate your PCB design and ensure that it meets the intended specifications and requirements. It helps identify potential issues or flaws in the design that may have been overlooked during the initial stages.

- Functionality Testing: By creating a physical prototype, you can test the actual functionality of your electronic circuit or device. This hands-on testing can reveal potential problems or limitations that may not have been apparent during simulations or theoretical analysis.

- Hardware and Software Integration: A PCB prototype enables you to integrate and test the hardware components with the corresponding software or firmware, ensuring compatibility and proper functionality.

- Cost and Time Savings: Identifying and addressing issues early in the development process through prototyping can save significant time and costs compared to discovering problems later during full-scale production.

- Investor and Stakeholder Confidence: A tangible PCB prototype can help demonstrate the viability and progress of your project to investors, stakeholders, or potential customers, increasing confidence and facilitating further development or funding.

- Refinement and Iteration: Prototyping allows for iterative refinement and improvement of the design based on feedback and testing results, enabling you to make necessary modifications before finalizing the production version.

By investing time and effort in creating a PCB prototype, you can minimize risks, validate your design, and increase the chances of success for your electronic product or project.

Design Phase

The design phase is the foundation of the PCB prototyping process. It involves creating the schematic and layout designs that will serve as the blueprint for your PCB prototype. Here are the key steps involved in the design phase:

Schematic Capture

The first step in the design process is to create a schematic diagram that represents the logical connections and relationships between the various electronic components that will be used in your circuit. This can be done using specialized electronic design automation (EDA) software or computer-aided design (CAD) tools.

The schematic capture process involves placing and connecting the necessary components, such as integrated circuits (ICs), resistors, capacitors, and connectors, based on the desired functionality and specifications of your electronic device or circuit.

PCB Layout Design

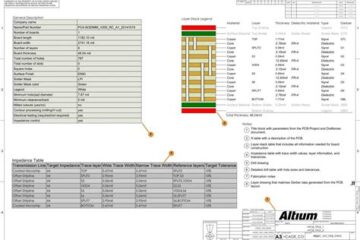

Once the schematic diagram is complete, the next step is to translate it into a physical PCB layout design. During this stage, you will use PCB design software to determine the placement of components, routing of traces (conductive paths), and the location of vias (conductive pathways between layers).

The PCB layout design process involves careful consideration of various factors, such as component spacing, trace widths and clearances, layer stackup, thermal management, and signal integrity. A well-designed PCB layout can greatly impact the performance, reliability, and manufacturability of your electronic device.

Design Rule Checking (DRC)

Before finalizing your PCB design, it’s essential to perform a thorough Design Rule Checking (DRC) process. DRC ensures that your design adheres to the manufacturing specifications, design guidelines, and industry standards set by the PCB fabrication service provider.

The DRC process identifies and highlights any violations or potential issues in your design, such as trace width or spacing violations, clearance violations, or missing components. Addressing these issues during the design phase can prevent costly mistakes and ensure a smoother fabrication process.

Prototype Fabrication Options

Once your PCB design is complete and validated, the next step is to fabricate the physical PCB prototype. There are several options available for PCB prototype fabrication, each with its own advantages and limitations. The choice of fabrication method will depend on factors such as complexity, turnaround time, cost, and desired prototype quality.

Traditional PCB Fabrication

Traditional PCB fabrication involves outsourcing the manufacturing process to a professional PCB fabrication service provider. These companies have specialized equipment and facilities to produce high-quality PCBs in various quantities, from prototypes to large-scale production runs.

The traditional fabrication process typically involves several steps, including:

- Uploading your design files (Gerber files) to the service provider’s online portal or sending them directly.

- Selecting the desired PCB specifications, such as layer count, material, surface finish, and quantity.

- Reviewing and approving a quote for the fabrication costs.

- Waiting for the fabrication process to be completed, which can take several days to a few weeks, depending on the service provider and the complexity of your design.

- Receiving the fabricated PCB prototypes via shipping.

Traditional PCB fabrication is known for producing high-quality prototypes and supporting a wide range of materials, layer counts, and specifications. However, it can be more expensive and have longer lead times compared to some other prototyping methods.

In-House Prototyping Methods

For those with access to the necessary equipment and resources, in-house prototyping methods can be an attractive option. These methods allow for faster turnaround times and greater control over the prototyping process. Some common in-house prototyping techniques include:

- Milling/Routing: Using a computer-controlled milling or routing machine, copper-clad boards can be engraved or etched to create the desired circuit patterns. This method is suitable for simple, single-layer or double-layer PCB designs.

- Chemical Etching: In this process, a copper-clad board is coated with a photoresist material, and the circuit pattern is transferred using a UV exposure process. The exposed areas are then chemically etched away, leaving the desired circuit pattern.

- 3D Printing: With the advent of conductive and insulating 3D printing materials, it’s possible to 3D print PCBs directly. While this method is still evolving, it offers the potential for rapid prototyping of complex designs with embedded components.

In-house prototyping methods can be cost-effective for small production runs or simple designs, but they may have limitations in terms of complexity, layer count, and overall quality compared to professional fabrication services.

Online PCB Prototyping Services

In recent years, several online PCB prototyping services have emerged, offering convenient and accessible options for hobbyists, makers, and small-scale developers. These services provide a user-friendly interface for uploading designs, selecting options, and ordering PCB prototypes.

Some popular online PCB prototyping services include:

- PCBWay

- JLCPCB

- Aisler

- OSH Park

- DirtyPCBs

These services typically offer quick turnaround times (often within a week or less), competitive pricing, and a range of options for materials, layer counts, and surface finishes. While the capabilities of online prototyping services may be more limited compared to traditional fabrication houses, they can be an excellent choice for simple to moderately complex designs and fast iterations.

| Prototype Fabrication Option | Advantages | Disadvantages |

|---|---|---|

| Traditional PCB Fabrication | High quality, wide range of options, suitable for complex designs | Longer lead times, higher cost |

| In-House Prototyping Methods | Fast turnaround, cost-effective for simple designs, greater control | Limited complexity, layer count, and quality |

| Online PCB Prototyping Services | Convenient, user-friendly, quick turnaround, competitive pricing | Potentially limited capabilities for complex designs |

Preparing for Fabrication

Before submitting your PCB design for fabrication, it’s important to prepare the necessary files and documentation. This step ensures a smooth fabrication process and helps avoid potential delays or issues.

Gerber File Generation

Most PCB fabrication service providers require design files in the Gerber format, which is an industry-standard file format for PCB fabrication. Gerber files contain the necessary information for each layer of the PCB, including copper layers, solder masks, silkscreens, and drill files.

Your PCB design software should have the capability to generate Gerber files from your PCB layout. It’s crucial to carefully review the generated Gerber files for any errors or inconsistencies before submitting them for fabrication.

Bill of Materials (BOM)

A Bill of Materials (BOM) is a comprehensive list of all the electronic components required for your PCB design. This document is essential for the assembly process, as it provides information about the specific components, their quantities, and their reference designators on the PCB.

Creating an accurate BOM is crucial to ensure that you have all the necessary components for assembly and that the correct components are used in their respective locations on the PCB.

Assembly Drawings

In addition to the Gerber files and BOM, it’s beneficial to provide assembly drawings or instructions to the PCB fabrication service provider. Assembly drawings can include details such as component placement diagrams, orientation markers, and any special assembly instructions or notes.

These drawings help streamline the assembly process and ensure that the components are placed correctly on the PCB, reducing the risk of errors and potential rework.

Ordering Your PCB Prototype

With your design files and supporting documentation ready, the next step is to place your order for the PCB prototype with a fabrication service provider.

Choosing a Fabrication Service

Selecting the right fabrication service provider is crucial for ensuring a successful prototyping experience. Consider the following factors when choosing a provider:

- Capabilities and Specifications: Ensure that the service provider can meet the requirements of your PCB design, including layer count, board size, and any specialized features or materials.

- Turnaround Time: Evaluate the quoted lead times and determine if they align with your project timeline and prototyping needs.

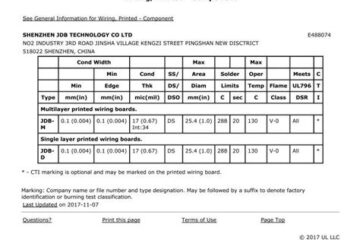

- Quality Standards: Look for service providers that adhere to industry standards and have established quality control processes in place.

- Customer Support: Consider the level of customer support offered by the service provider, as well as their responsiveness and communication during the ordering and fabrication process.

- Pricing and Minimums: Compare pricing structures and minimum order quantities across different service providers to find the best value for your project.

- Reviews and Reputation: Research the service provider’s reputation by reading customer reviews and feedback from online forums or communities.

Submitting Your Design

Once you’ve selected a fabrication service provider, you’ll need to submit your design files and supporting documentation through their online portal or by following their specified submission process.

Most service providers will have an online interface where you can upload your Gerber files, BOM, assembly drawings, and any other required documentation. Be prepared to provide detailed information about your design, such as layer count, material preferences, and any specific instructions or requirements.

Selecting Options and Customizations

During the ordering process, you’ll typically have the opportunity to select various options and customizations for your PCB prototype. These may include:

- PCB Material: Choose the base material for your PCB, such as FR-4 (fiberglass reinforced epoxy), polyimide, or other specialized materials.

- Layer Count: Specify the number of conductive layers required for your design (e.g., 2-layer, 4-layer, or more).

- Surface Finish: Select the desired surface finish for your PCB, such as lead-free HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or immersion silver.

- Solder Mask and Silkscreen Colors: Customize the colors of the solder mask and silkscreen layers for aesthetic or functional purposes.

- Board Outline and Dimensions: Define the overall size and shape of your PCB, including any non-rectangular outlines or cutouts.

- Delivery Options: Choose the shipping method and delivery timeframe that best suits your project timeline.

Review all the available options carefully and make selections that align with your design requirements and project constraints.

PCB Assembly

After the fabrication of your PCB prototype, the next step is to assemble the electronic components onto the board. There are several options available for PCB assembly, ranging from manual assembly to professional assembly services.

Component Sourcing

Before assembling your PCB prototype, you’ll need to source all the necessary electronic components listed in your Bill of Materials (BOM). There are several options for sourcing components, including:

- Online Component Distributors: Websites like Digi-Key, Mouser Electronics, and Arrow Electronics offer a wide range of electronic components from various manufacturers, making it convenient to source components for your project.

- Local Electronics Stores: If you have access to local electronics stores or distributors, you may be able to purchase components in person, which can be helpful for small quantities or specialized components.

- Salvaging Components: For hobbyists or those on a tight budget, salvaging components from old or broken electronics can be a cost-effective option, but it requires careful testing and verification.

When sourcing components, pay close attention to the specific part numbers, package types, and any additional specifications listed in your BOM to ensure compatibility with your PCB design.

Manual Assembly

If you have the necessary skills and tools, you can opt for manual assembly of your PCB prototype. Manual assembly involves the following steps:

- Component Preparation: Organize and prepare the components according to the BOM and assembly drawings, ensuring that each component is correctly identified and ready for placement.

- Component Placement: Carefully place each component onto the PCB, following the placement guides and orientation markers provided in the assembly drawings.

- Soldering: Use a soldering iron or a hot air rework station to solder the components onto the PCB, ensuring proper electrical connections and mechanical stability.

- Inspection: Perform a thorough visual inspection of the assembled PCB to identify any misplaced components, solder bridges, or other defects.

Manual assembly can be a cost-effective option for simple designs or small production runs, but it requires patience, steady hands, and soldering skills. It’s important to take necessary precautions, such as using anti-static measures and proper soldering techniques, to avoid damaging the components or the PCB.

Professional Assembly Services

For more complex designs, larger production runs, or when time is of the essence, you may choose to outsource the assembly process to a professional assembly service provider. These companies specialize in PCB assembly and have the necessary equipment, expertise, and quality control measures in place to ensure accurate and reliable assembly.

Many PCB fabrication service providers also offer assembly services, making it convenient to have both the fabrication and assembly handled by a single provider. However, you can also opt for dedicated assembly service providers if desired.

When using professional assembly services, you’ll typically need to provide the fabricated PCB prototypes, the BOM, and any assembly instructions or drawings. The service provider will then source the necessary components, perform the assembly, and conduct final testing and inspection before shipping the assembled PCB prototypes back to you.

Professional assembly services can be more expensive than manual assembly, but they offer several advantages, including:

- Faster turnaround times

- Improved accuracy

0 Comments