Introduction

For engineers and product developers, finding a reliable PCB (printed circuit board) prototype fabrication service is a crucial step in bringing new products to market. Partnering with the right prototype PCB manufacturer can greatly accelerate the iterative design process and allow you to validate functionality faster. This guide covers the key factors to evaluate when selecting a fabrication service for prototype printed circuit boards.

Capability Range

The first aspect to examine is the prototype fabrication service’s technological capability in key areas:

Layer Count

| Layer Count | Applications |

|---|---|

| 2-6 layers | Suitable for simple, low-cost boards |

| 8-12 layers | Mid-complexity boards with high component density |

| 14-30+ layers | Very complex boards like ASICs, HDI |

Choose a service capable of handling the layer counts needed for both your current and future projects.

Line Width/Space

The minimum trace width and spacing is measured in mils (1 mil = 1/1000 inch).

| Line/Space | Description |

|---|---|

| 6 mil | Only suitable for simple boards |

| 4 mil | Allows high component density |

| 2 mil or less | Needed for advanced HDI boards |

Evaluate if the service can meet your line width and space requirements.

Solder Mask Type

LPI (Liquid Photoimageable) solder mask is preferred vs. dry film for its durability, resolution and quality.

Surface Finishes

ENIG (Electroless Nickel Immersion Gold) offers the best performance for prototypes. Avoid services using outdated HASL (Hot Air Solder Leveling).

Panel Sizes

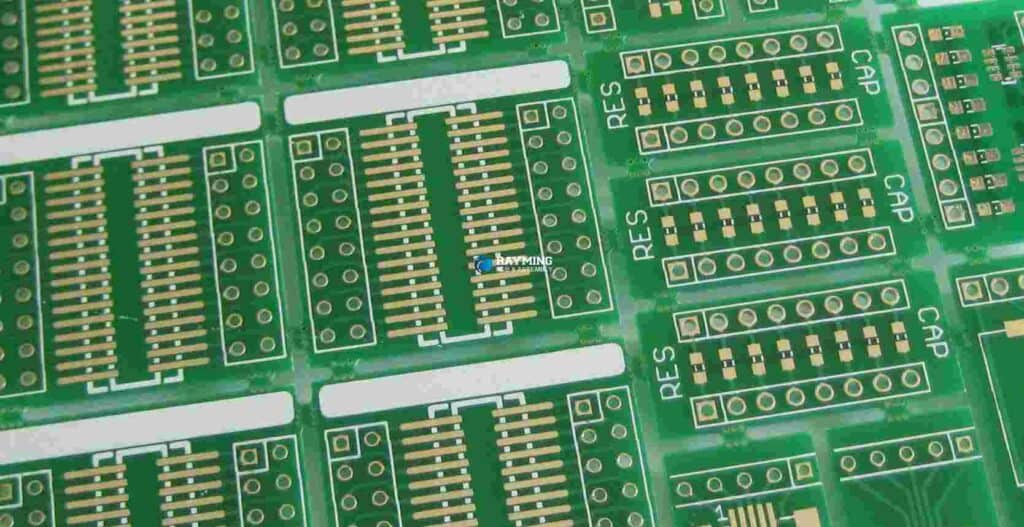

Larger panel sizes improve efficiency and cost for volume production. But individual boards may suit lower volume prototyping better.

Quick Turnaround

Look for 3-5 day typical turn times from order to delivery for fastest results. Some services offer 24-48 hour rush service.

Quality Processes

For prototype boards, quality should not be compromised just to save on cost. Here are key process and certifications to look for in a fabrication service:

- IPC Certification – IPC standards represent the pinnacle of quality in PCB fabrication. Choose a service with IPC 6012 Qualification and IPC-A-610 Acceptability certs.

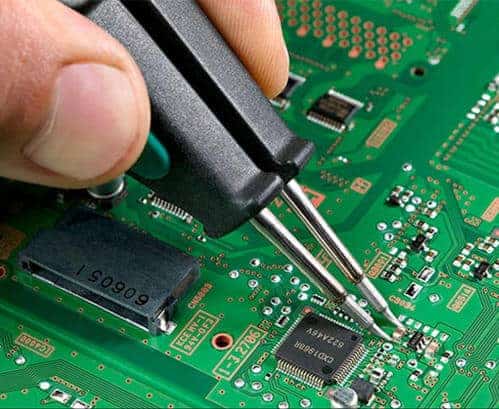

- Validation Testing – Rigorous electrical testing, flying probe, boundary scan and netlist testing to validate the design data and fabricated boards.

- AOI Inspection – Automated optical inspection to check solder mask registration, clearances etc. Identifies errors human inspectors could miss.

- Test Points – Inclusion of test points/coupons on panel boards provides means to physically measure quality.

- CAM Department – Dedicated engineering staff to analyze designs for manufacturability and resolve any issues prior to fabrication.

Additional Services

The best PCB prototype services provide a comprehensive range of value-added services:

Assembly

Full assembly of printed circuit boards, not just bare PCBs. Services may offer:

- SMT Assembly – Soldering of surface mount components to the fabricated boards.

- Thru-hole Assembly – Attachment of leaded components like connectors.

- Box Build – Full assembly of a product including PCBs, chassis, cabling etc.

Component Procurement

Sourcing of required components for assembly through the service’s supply chain.

Functional Testing

Assistance with test plan development and performing functional tests on assembled boards.

DFM Analysis

Review of board designs by engineers to identify any manufacturability or performance issues.

Design Support

Quick feedback and real-time communication with PCB designers to resolve fabrication issues and optimize the design as needed.

Location Proximity

For fastest turnaround on prototypes, using a fabrication service in your geographic region is advantageous to avoid long shipping times. For example:

- North America for US-based companies

- Europe for EU-based companies

- Asia for companies in APAC region

Visiting the fabrication facility for audits may also be beneficial.

Credentials

These credentials validate the qualifications and capabilities of the PCB prototype fabrication service:

- IPC membership and certifications

- ISO 9001 registered quality processes

- ITAR registration if required for your project

- Long history specializing in prototype PCB fabrication vs other services like volume production or PCB design.

- Excellent customer reviews, testimonials and references.

Summary

Choosing the right PCB prototype fabrication partner requires evaluating their technological capabilities, quality systems, value-added services, location and credentials thoroughly. Taking the time to qualify suppliers will forge a partnership that enables faster prototyping iteration and efficient design validation.

Frequently Asked Questions

Q: What are the main benefits of using a dedicated prototype PCB fabrication service vs. a generic PCB manufacturer?

A: Specialized prototype services offer:

- Faster lead times to support rapid iteration.

- Higher quality standards critical for prototyping.

- Services aimed specifically at low volume prototyping.

- Staff experienced in supporting prototype work.

- Priority given to quick-turn prototyping work.

Q: Should every design iteration use a separate PCB fabrication service?

A: Not necessarily. While switching services can provide comparison, finding one reliable partner with proven quality enables building a relationship and streamlining logistics for future projects. Iterating all prototypes with one fabrication expert is usually ideal.

Q: What key performance indicators should be examined when qualifying a potential PCB prototype partner?

A: Key performance metrics include:

- On-time delivery percentage

- First pass yield percentage

- Quality data such as Cpk levels

- Customer satisfaction and return rate

- Measurement of key process capabilities

- ITAR compliance status if required

- IPC certification levels

Q: What questions should I ask PCB prototype services when evaluating them?

A: Key questions to ask include:

- What is your full range of technological capabilities?

- How do you ensure quality and consistency?

- What certifications and qualifications do you hold?

- What value-added services do you offer beyond fabrication?

- Can your engineers review designs for feedback?

- What are standard lead times for prototype orders?

- Do you have optimized quick-turn processes?

- How do you support customers throughout prototyping?

Q: What are some best practices when partnering with a PCB prototype fabrication service?

A: Best practices include:

- Engage the service’s engineers to review designs early for feedback.

- Clearly communicate prototyping needs, expectations and schedule.

- Iterate each prototype run based on lessons learned.

- Provide comprehensive design data to the service.

- Establish a single point of contact for streamlined communication.

- Provide timely feedback and evaluation of each prototype run.

- Share future project roadmaps for forecasting.

0 Comments