Introduction

For engineers developing new electronic products, having prototype circuit boards assembled professionally is critical for design validation and testing. Partnering with the right contract assembler enables populating printed circuit boards with components efficiently so developers can focus on design iteration. This guide covers how to select a prototype circuit board assembly partner.

Assembly Technology

The assembler should offer a range of assembly capabilities:

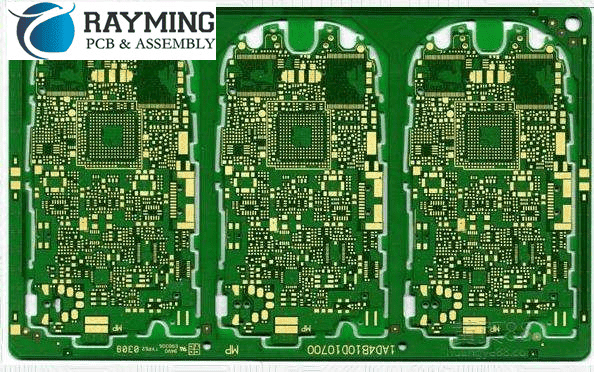

SMT Assembly

Soldering surface mount components onto PCBs using SMT (surface mount technology) equipment.

Through-Hole Assembly

Manual assembly of leaded components by inserting and soldering them into plated through-holes.

Box Build Assembly

Populating an entire electromechanical assembly including PCBs, connectors, cables, and other components.

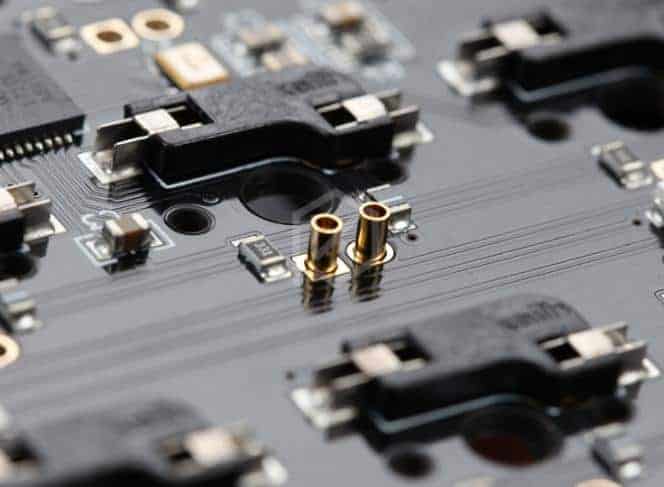

BGA Assembly

Soldering difficult BGA (ball grid array) packages requiring specialized techniques.

Flexible Circuits

Assembling flexible PCBs which require special handling and process care.

Rework Capability

Skilled operators able to efficiently modify or repair assembled boards as needed.

Component Handling

Proper storage, kitting, and handling of components is crucial:

- ESD Control – Use of antistatic packaging, wrist straps, and grounded workstations.

- Moisture Sensitivity – Adherence to JEDEC standards for MSD components.

- Inventory – Use of feeders, trays, reels, tubes, etc. to organize components.

- Traceability – Clear labeling indicating reel/tray source and quantity available.

Quality and Inspection

Thorough quality control prevents defects:

- IPC Standards – IPC-A-610 sets assembly quality requirements. J-STD-001 covers soldering.

- First Article Inspection – Detailed inspection of the first assembled board.

- AOI – Automated optical inspection checks for assembly issues.

- Testing – In-circuit and functional testing verifies boards operate properly.

- Quality Control – Statistical process control, operator certification, corrective actions.

Supply Chain Management

The assembler should be able to procure needed components:

- Bill of Materials Kitting – Supplying all components required for each assembly build.

- Long Lead-time Parts – Early forecasting and ordering of longer lead-time ICs and other components.

- Inventory Management – Tracking inventory on-hand and re-ordering thresholds for each part number.

- Counterfeit Avoidance – Procuring only from authorized distributors and manufacturers.

Engineering Support

Look for assemblers providing engineering services like:

- DFM Analysis – Review of the PCB design for manufacturability and testability.

- BOM Optimization – Substituting more cost-effective component packages/values when feasible.

- Design For Test – Adding test points, connections to support testing needs.

- Fixture Design – Designing fixtures to aid in assembling or testing boards.

Location and Logistics

For rapid turnaround on prototypes, an assembler located nearby is advantageous:

- North America for companies in USA and Canada

- Europe for companies located in EU region

- Asia for companies in APAC countries

This avoids long lead times due to international shipping.

Summary

Choosing the right prototype circuit board assembly partner requires evaluating capabilities, quality processes, supply chain management, engineering support, and location. Taking time to qualify assemblers will pay dividends through accelerated prototyping and new product introduction down the road.

Frequently Asked Questions

Q: What are the main benefits of outsourcing prototype circuit board assembly versus doing it in-house?

A: Benefits of outsourcing include:

- Avoiding large equipment capital investment.

- Leveraging the assembler’s expertise and best practices.

- Focusing internal resources on core competencies rather than assembly process.

- Faster turnaround compared to hiring and training internal staff.

- Ability to scale up/down flexibly based on needs.

- Access to a wider range of assembly technology and services.

Q: What risks need to be managed when outsourcing prototype assembly?

A: Risks to manage include:

- Quality problems due to poor process control.

- Supply chain delays impacting component availability.

- Lack of communication leading to misunderstandings.

- Hidden costs if requirements change frequently.

- Long turnaround times negating benefits of outsourcing.

- IP protection concerns when working with an external party.

Q: What documentation does the assembler need for building prototypes?

A: Key documentation required:

- Bill of Materials listing all components.

- PCB fabrication and layout files.

- Assembly drawings indicating placement.

- Pick and place files for SMT programming.

- Solder paste stencil or solder file.

- Any specialized assembly instructions.

Q: What questions should I ask potential prototype assembly partners?

A: Key questions to ask:

- What assembly capabilities and services do you offer?

- How do you ensure quality and process control?

- How will you manage the supply chain and component procurement?

- What engineering support services are available?

- What are your standard and expedited lead times?

- What ITAR and data security practices do implement?

- Can I visit your facility for an audit?

Q: What best practices help ensure a successful project with an assembler?

A: Best practices include:

- Doing DFM analysis before finalizing board designs.

- Providing component requirements and BOM early.

- Communicating expectations and target deadlines clearly.

- Scheduling regular check-ins and status updates.

- Being flexible to support the assembler when feasible.

- Providing thorough feedback after builds to improve next time.

- Building a partnership relationship with the assembler.

0 Comments