Introduction

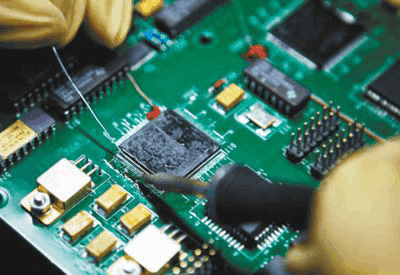

Electronic assembly manufacturing refers to the process of assembling electronic components into circuit boards or other electronic devices. It is a crucial part of the electronics supply chain, taking electronic components like transistors, resistors, capacitors and integrated circuits (ICs) and soldering them onto printed circuit boards (PCBs). The assembled PCBs form the core of all electronic products like computers, mobile devices, appliances, automotive electronics and industrial equipment. This article provides an overview of the key processes, industry trends and major players in electronic assembly manufacturing.

Key Processes

SMT Assembly

Surface mount technology (SMT) assembly involves placing surface mount devices (SMDs) onto PCBs. SMDs are electronic components that are designed to be soldered directly onto the surface of PCBs rather than using thru-hole technology with component leads inserted into holes. The main steps in SMT assembly are:

- Solder Paste Printing – Solder paste is applied on PCB pads where components will be placed. This is done using stencils and solder paste printers.

- Component Placement – Pick and place machines use vacuum nozzles to pick SMDs and accurately place them onto the solder paste.

- Reflow Soldering – The PCB goes through a reflow oven to heat the solder paste, causing it to melt and creating solder joints to attach components.

Through Hole Assembly

Some components like connectors and heat sinks are still assembled using through hole technology. The main steps are:

- Component Insertion – Components leads are inserted into the plated through holes in the PCB.

- Soldering – The underside of the PCB is wave soldered to form the solder joints.

- Trimming/Clinching – Excess component leads are trimmed off and clinched down flush to the PCB.

Box Build Assembly

This involves adding other components like cables, batteries and enclosures to assemble the final product:

- Cable/Wire Harness Assembly – Cutting, crimping and assembling cable wiring harnesses

- Battery Installation – Mounting and connecting batteries to PCBs

- Enclosure Assembly – Assembling the product into its plastic or metal enclosure

- Functional Testing – Testing assembled devices for functionality

Process Table

| Process | Steps |

|---|---|

| SMT Assembly | – Solder Paste Printing <br>- Component Placement <br>- Reflow Soldering |

| Through Hole Assembly | – Component Insertion<br>- Soldering<br>- Trimming/Clinchin |

| Box Build Assembly | – Cable/Wire Harness Assembly<br>- Battery Installation<br>- Enclosure Assembly<br>- Functional Testing |

Industry Trends

Miniaturization

As electronic devices get smaller and more portable, PCB assemblies are becoming more compact and complex. This requires assembling and soldering smaller SMD components with reduced lead pitches.

Automation

Automated assembly using robotic assembly systems helps improve precision and efficiency. Advanced vision systems enable more accurate component placement and solder joint inspection.

Flexible & Hybrid PCBs

Flexible PCBs and hybrid PCB assemblies combining rigid and flexible PCBs in innovative mechanical designs are growing in popularity. These require specialized assembly processes.

Outsourcing

Many electronics firms, especially in consumer segments, are moving to an outsourced manufacturing model. Outsourced assembly providers can offer expertise, economies of scale and proximity to target markets.

Key Industry Players

Some of the top companies in electronic assembly manufacturing include:

- Jabil Circuit: One of the world’s largest electronic manufacturing service (EMS) providers offering specialized services like microelectronics assembly.

- Foxconn: Leading EMS company focused primarily on consumer electronics assembly for major brands.

- Flex: Provides “sketch-to-scale” services covering the entire product lifecycle including design, engineering and assembly.

- Sanmina Corporation: Offers PCB assembly, systems integration and complete product build services.

- Benchmark Electronics: Global provider of integrated engineering, design and manufacturing services.

- Plexus: Services a variety of industries including networking/communications, healthcare, aerospace/defense, etc.

Frequently Asked Questions

Q1: What are the most common SMT components used in PCB assemblies?

Some of the most common SMT components are:

- Passive components like resistors, capacitors and inductors

- Semiconductor ICs like microcontrollers, memory and microprocessors

- Discrete semiconductors like diodes and transistors

- Connectors like USB, D-Sub, RJ45 etc.

- LEDs, oscillators, crystals and various sensors

Q2: How is yield maximized in electronic assembly?

Maximizing assembly yield requires:

- High precision SMT pick-and-place machines to avoid placement defects

- Matching reflow profiles to paste/components to prevent solder defects

- Inspection systems to catch errors early before value-add steps

- Statistical process control tracking and optimization

- High quality components sourced from reliable suppliers

Q3: What file formats are used in PCB assembly data?

Common file formats include:

- Gerber files – Used for PCB fabrication data

- IPC-D-356 Netlist files – Contain PCB component data for assembly

- ODB++ files – Provide complete PCB product definition

- IPC-2581 – Newer standard for complete PCB assembly/manufacturing data

Q4: What are some key SMT equipment used in assembly?

- Solder paste printers – Apply solder paste on PCBs

- Pick-and-place machines – Automate high-speed component population

- Reflow ovens – Form solder joints by heating paste to melting point

- AOI systems – Automated optical inspection to identify defects

- X-ray systems – Detect faults like shorts or open joints

Q5: How is box build assembly done for low versus high volume products?

For low volumes, manual assembly on benches may be used. For higher volumes, assembly steps are automated using mechanisms like:

- Conveyor systems to move PCBs through assembly cells

- Robotic arm platforms to repeatedly pick and place components

- Automated testing systems for functional test

- Advanced vision systems for automated inspection

- Barcode scanning and product tracking for quality control

0 Comments