Introduction

The electronics manufacturing industry is experiencing rapid growth driven by advancements in technology and rising demand for electronic products across sectors like automotive, aerospace, medical devices, and consumer electronics. As original equipment manufacturers (OEMs) focus on their core competencies of design and innovation, they are increasingly leveraging the expertise of specialized electronic manufacturing services (EMS) providers for assembling and producing electronic components and products.

This article provides a comprehensive overview of electronic assembly companies – examining the key services they offer, benefits of outsourcing to them, how to select the right partner, major industry players, and the outlook for the electronic manufacturing services industry.

Key Services Offered by Electronic Assembly Companies

Electronic assembly companies, also referred to as electronic manufacturing services (EMS) providers, offer end-to-end manufacturing services to OEMs seeking to outsource some or all of their electronic production needs. Here are the key services offered:

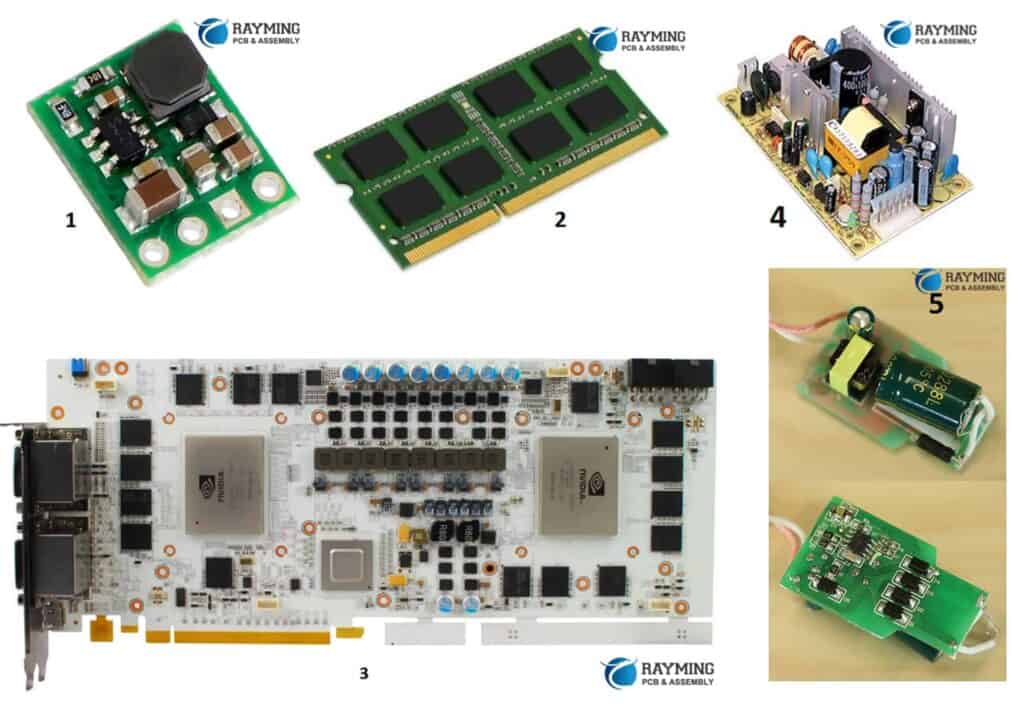

PCB Assembly

This involves assembling printed circuit boards (PCBs) by soldering components like capacitors, resistors, integrated circuits onto the boards. Services include:

- SMT (Surface Mount Technology) Assembly – assembling surface mount devices (SMDs)

- Through Hole Assembly – inserting components with wire leads into holes in PCBs

- In-Circuit Testing – testing partially assembled PCBs

- Box Build Assembly – assembling fully tested PCBs into an enclosure

Component Sourcing & Procurement

EMS partners can procure all the required components like semiconductors, passives, connectors, electromechanical parts on behalf of OEMs.

Product Testing & Certification

They offer testing services like flying probe testing, boundary scan testing and can obtain certification like UL, CE marking.

New Product Introduction (NPI)

They provide support during the new product development and introduction phase including prototyping, design for manufacturing (DFM) and test engineering services.

Supply Chain Management

EMS providers can take over supply chain activities like demand forecasting, inventory management and logistics.

Post Manufacturing Support

This includes services like product repair, refurbishment, spare parts management and obsolescence mitigation.

Final Product Assembly & Integration

For final finished products, they can provide system integration, perform customization and distribution.

Benefits of Outsourcing to an Electronic Assembly Company

OEMs stand to gain multiple benefits by outsourcing manufacturing and assembly of electronic products to specialized EMS partners:

Focus on Core Competencies

Outsourcing allows OEMs to free up resources to focus on innovation, design and product development – their key areas of expertise.

Reduced Operating Costs

EMS providers can achieve manufacturing cost savings through economies of scale, specialization and access to lower cost global supply chains. These savings can be passed on to OEM customers.

Improved Quality

By leveraging expertise of EMS companies in quality control and process optimization, OEMs can improve product quality and reliability.

Faster Time to Market

EMS partners maintain ready availability of components and production capacity, which enables bringing products faster to market and responding quicker to emerging opportunities.

Flexibility & Scalability

OEMs can easily scale production up or down through an EMS partner. The EMS absorbs fluctuations, providing greater manufacturing flexibility.

Single Point of Contact

Rather than coordinating with multiple suppliers, OEMs can leverage a single EMS partner to manage all manufacturing and supply chain activities.

Access to Advanced Technologies

EMS companies invest in deploying the latest production technologies like automation, IoT and analytics. OEMs can leverage this to manufacture advanced electronics products.

How to Select the Right EMS Partner

OEMs should evaluate electronic assembly companies on the following key aspects before selecting the right outsourcing partner:

Technical Capabilities & Expertise

Examine their experience and expertise across technologies like SMT, through hole assembly, automation, test engineering required for your product.

Quality Systems

Review certifications like ISO 13485, IATF 16949 and internal quality processes. Also assess capabilities for regulatory compliance.

Customer Service Record

Check their track record of delivering high quality products on time to customers through metrics like on-time delivery, customer satisfaction.

Location & Logistics Set-up

Evaluate their global footprint and logistics capabilities to identify if they can effectively support your supply chain needs.

Pricing & Contract Models

Assess if their pricing models and minimum order quantities are aligned to your production volumes and business needs.

Financial Strength

Partner with EMS companies that demonstrate solid financial health and growth to support current and future outsourcing needs.

Technology Roadmap

Prioritize partners who share future technology vision and have roadmaps aligned with your product innovation plans.

Cultural Fit

Ensure alignment on aspects like values, communication and transparency for a mutually productive relationship.

Major Players in the Electronic Assembly Industry

Some of the leading global electronic manufacturing services companies include:

Jabil Circuit

One of the top EMS companies, they generated $32.8 billion in revenue in 2022. They have over 100 plants globally and serve various industries like automotive, healthcare, 5G infrastructure.

Flex Ltd.

With $28.4 billion revenue in 2022, Flex has 30+ years of EMS experience and 200,000 employees in 100 sites across 30 countries. They serve industries ranging from aerospace to clean tech.

Sanmina Corporation

A leading EMS company with 2022 revenue of $20.1 billion, Sanmina provides complete end-to-end manufacturing solutions to OEMs and has a global footprint of over 130 facilities.

Benchmark Electronics

Benchmark is a Texas-based EMS company serving major sectors like medical, aerospace, defense, semiconductor with specialized engineering and new product introduction services. 2022 revenue was $2.7 billion.

Celestica

Headquartered in Toronto, Celestica has revenues of $6.5 billion and provides high-mix, low-volume and after-market supply chain services to Fortune 500 companies.

Plexus

With 2022 revenue at $3.8 billion, Plexus specializes in serving mid-to-low volume, highly complex products for sectors like healthcare, industrial, communications.

Key Tronic

Key Tronic is a full-service EMS company providing PCB assemblies, full product builds, testing services and logistic solutions primarily to technology companies. 2022 revenue was $472 million.

Nortech Systems

Minnesota-based Nortech offers value-added engineering and manufacturing services for medical, industrial, military and commercial OEMs with revenue of $119 million in 2022.

IEC Electronics

New York-based IEC provides electronic manufacturing and cable assembly services for medical, aerospace, industrial and military applications. 2022 revenue was $156 million.

Outlook for the Electronic Manufacturing Services Industry

The global electronics manufacturing services market size was valued at $556 billion in 2022 and is projected to grow at a CAGR of 3.4% from 2023 to 2030 to reach nearly $750 billion according to Verified Market Research. Here are some key trends shaping the positive outlook for the EMS industry:

- Continued outsourcing of electronics production by OEMs to reduce costs and enable innovation.

- Rising demand for EMS across diverse end markets like electric vehicles, renewable energy, 5G equipment.

- Investment by EMS companies in Industry 4.0 technologies like IoT, analytics, automation.

- Geographic expansion by EMS providers into emerging markets to diversify manufacturing footprint.

- Consolidation among EMS companies to gain scale, capabilities and geographic access.

- Increasing demand for end-to-end solutions encompassing design, engineering, aftermarket services.

- Focus on capabilities like rapid prototyping and new product introduction services.

In summary, driven by the rising complexity of electronic products and need for specialized manufacturing expertise, OEMs are projected to further increase outsourcing to trusted EMS partners. Leading electronic assembly companies are gearing up capabilities and capacity to cater to diverse customer requirements across industries and geographies.

Frequently Asked Questions

What are the typical capabilities of mid-sized electronic assembly companies?

Mid-sized electronic assembly companies typically have capabilities for providing the full range of electronic manufacturing services but at smaller scale than the giant EMS companies. They focus on PCB assemblies, box builds, tests, supply chain support and some even offer product design and NPI services – catering to mid-to-low volume complex product requirements.

What role does quality play in selecting an EMS partner?

Quality should be a top priority in evaluating EMS providers. OEMs must review their quality certifications, internal processes, product rejection rates and history of delivering zero-defect products on time. EMS companies with robust quality systems minimize risks of product failures and associated recall costs for OEMs.

How are pricing models structured at electronic assembly companies?

EMS pricing models are based on cost of production plus a markup percentage. Cost varies with production volume, component types, testing needs, product complexity. Ongoing production pricing may start with 3-year contractual commitment on forecast volumes. NPI and prototype builds often use Time & Materials pricing. Minimum order quantities are also set.

What recent trends are transforming electronic assembly services?

Key trends transforming electronics assembly services include – shift to smart factory automation, adoption of digital twin and simulation technologies, increased focus on product data & traceability across supply chain through blockchain and IoT platforms and end-to-end solution approach encompassing design, engineering, logistics.

How can OEMs build strong strategic partnerships with EMS providers?

OEMs must engage EMS partners early during product development phase through collaborative design and prototyping. Sharing future product roadmaps, long-term volume forecasts and navigating technology disruptions jointly fosters strong strategic alignment. Maintaining transparency, open communication and building trust are also key.

0 Comments