The True Cost of PCB Assembly in 2023

Introduction

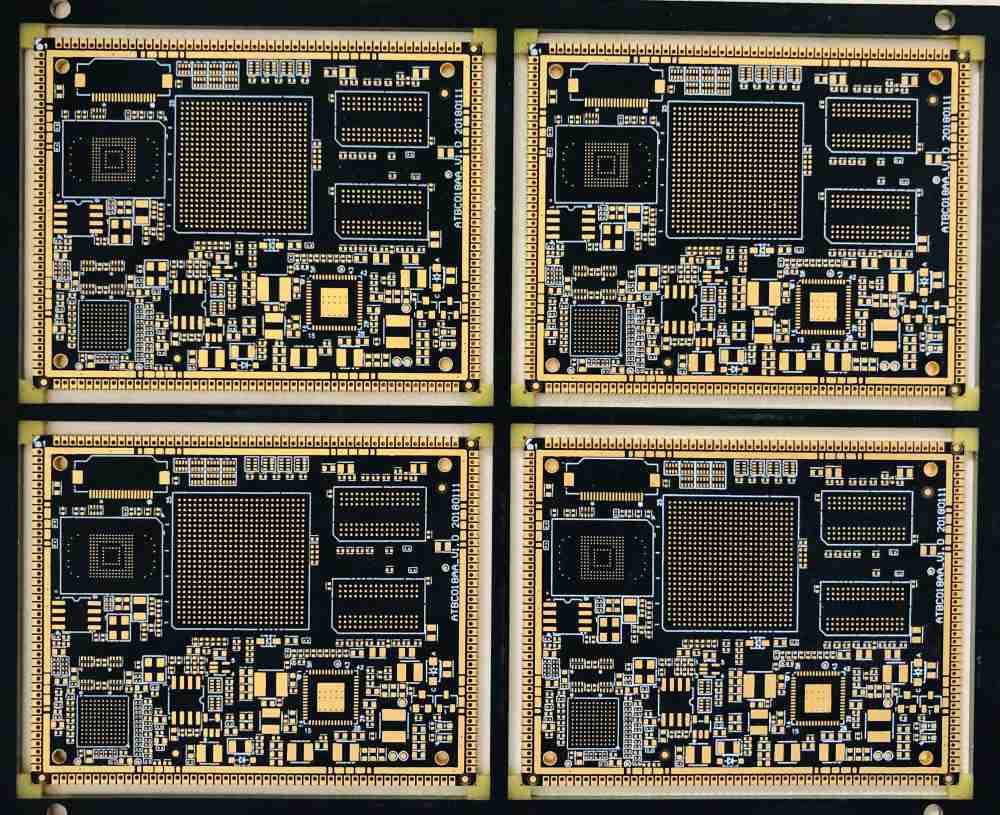

Printed circuit board (PCB) assembly is a crucial step in bringing an electronic product to life. However, the costs associated with PCB assembly are often unclear, especially for those new to electronics manufacturing. This article will break down the key factors that contribute to PCB assembly costs and provide realistic estimates for assembly in 2023.

What Goes Into PCB Assembly Costs?

There are several elements that make up the total cost of assembling a printed circuit board:

Component Costs

The bill of materials (BOM) refers to the list of electronic components required for the board. High-quality components from reliable suppliers naturally cost more. Unique or niche components can also drive up costs.

Board Fabrication

The PCB must first be fabricated, which has its own costs. More complex board designs require more layers and features, increasing fabrication expenses.

Assembly Labor

Paying workers to manually assemble PCBs takes time and labor. Automated assembly uses specialized machines, which have significant upfront costs.

Testing/Inspection

Every board needs testing to verify all components are present and functional. Automated optical inspection and electrical testing equipment is expensive.

Overhead Costs

Additional overhead costs include factory space, equipment maintenance, inventory, shipping, and project management labor.

Typical PCB Assembly Costs

Printed circuit board assembly costs ultimately come down to the specific components, complexity, order volumes, and assembly techniques used. Here are typical price ranges:<div>

| PCB Assembly Type | Typical Cost Per Board |

|---|---|

| Simple, manual assembly of a bare PCB with low-cost components in moderate volumes | $5 – $15 |

| SMT assembly of a medium complexity PCB with automated pick-and-place | $15 – $50 |

| High complexity PCBs with multiple layers, fine pitch components, and 100% automated assembly | $50 – $500 |

</div>

As a baseline, expect to pay $20 to $30 per board for moderately complex circuit boards assembled in China in quantities of 100-1,000 units. However, costs can easily reach $100+ for complex boards or those with high-end components.

Factors That Increase PCB Assembly Costs

Several key factors will drive PCB assembly costs higher, including:

Small Order Quantities

Setup costs are high for short production runs. Assembly pricing is optimized for orders of 1000+ units.

Component Selection

Uncommon or high-precision components that are difficult to source or install cost more.

High Component Counts

Boards with 500+ components require more assembly labor and inspection.

Dense PCB Design

Components placed very close together or boards with multiple layers make assembly challenging.

Automated Assembly

Advanced tools like automated SMT pick-and-place machines offer faster assembly but have high equipment costs.

Certifications

Medical, military, and other highly regulated industries require certified facilities and processes.

Geographic Location

Assembly in high-wage regions like North America or Europe is far more expensive than in Asia.

Optimizing PCB Assembly Costs

Here are some tips to optimize PCB assembly expenses:

- Use standardized, high-volume components when possible.

- Design for easier assembly: adequate spacing, component symmetry, etc.

- Build 3D models to prototype assembly process early.

- Order larger quantities of boards to benefit from volume discounts.

- If timing allows, manufacture in lower-cost regions like China.

- Verify assembly quotes match your exact BOM, design files, and volume needs.

Other Important PCB Assembly Considerations

While optimizing for cost is crucial, product quality and reliability are also vital:

- Work with assembly partners that have technical expertise, not just the lowest bid.

- Perform due diligence on partners: quality systems, technical capacity, communication skills.

- Thoroughly inspect assembled boards for errors – don’t assume full functionality.

- Run reliability tests: vibration, thermal shock, drop testing, etc.

- Consider risks like fluctuating lead times, tariffs, shipping delays. Diversify suppliers if possible.

Conclusion

While printed circuit board assembly was once an extremely manual process, advances in technology now enable everything from partially automated assembly lines to highly precise robotic manufacturing. However, these upgrades also increase costs. By designing intelligently, choosing the right components and partners, and ordering optimal quantities, you can balance cost with the reliability needs of your product. Use the estimates and tips above to budget realistically for your next PCB assembly project.

FAQ

What is the average cost per hour for manual PCB assembly?

Expect to pay $25 to $50 per hour for skilled manual labor and supervision for PCB assembly, depending on location. High-cost regions like the U.S. and Europe range from $40 to $100 per hour.

Does prototype PCB assembly cost more than production runs?

Yes, prototyping almost always costs more per board. The fixed costs of programming, set up, and tooling are amortized over small quantities, often 10-50 boards. Production pricing benefits from bulk discounts.

Can I get quotes for PCB assembly from multiple manufacturers?

Absolutely, it’s recommended to get 3-4 quotes. Ensure all suppliers receive the exact same BOM, Gerbers, and volume requirements for an apples-to-apples comparison. Watch for extreme high or low bids.

What are the most common assembly defects to look for?

Typical assembly issues include missing components, wrong or counterfeit parts, soldering problems like cold joints or bridges, damage during handling, and shorts or opens. Visually inspect boards and perform electrical testing.

How long does full turnkey PCB assembly usually take?

From the time PCB fabrication completes, expect around 15-20 days for assembly, testing, inspection, and shipment of a typical board. Lead times can stretch to 6-8 weeks for complex boards or populated backplanes. Discuss expected timelines with your assembly partner.

0 Comments