JLCPCB SMT Assembly: A Guide to Utilizing JLCPCB’s SMT Assembly Services

Introduction

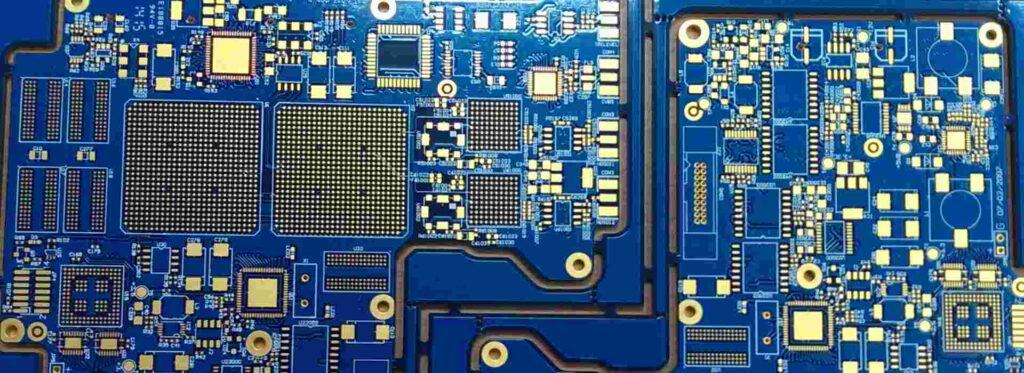

JLCPCB is one of the most popular PCB manufacturing and assembly services used by makers, hobbyists and engineers worldwide. Along with their PCB fabrication service, they also provide SMT assembly service which allows you to get professionally assembled boards ready for use.

SMT or Surface Mount Technology assembly involves mounting of surface mount components like resistors, capacitors, ICs etc. onto the PCB. This requires specialized equipment like pick and place machines. JLCPCB has heavily invested in advanced SMT assembly lines to provide quick and reliable assembly services.

In this comprehensive guide, we will explore JLCPCB’s SMT assembly service in detail – covering the assembly options, pricing, lead times, quality checks and other aspects.

Overview of JLCPCB’s SMT Assembly Service

JLCPCB provides two types of SMT assembly services:

1. Basic SMT Assembly

This is the standard assembly service for mounting SMT components only. Following are the key features of basic SMT assembly:

- Components supported: 0201 to 25 x 25 mm size SMT components

- Lead time: 2-3 days for prototypes, 7-9 days for small batches

- Quantity: Prototype (5 pcs minimum) and small-batch up to 2000 pcs

- Testing: Automated optical inspection (AOI) and bar code scanning

2. SMT + Through Hole Assembly

This is JLCPCB’s full turnkey PCB assembly service for mounting both SMT and through hole components. The key highlights are:

- Support for through hole components like connectors, pots, buttons etc.

- Additional process steps like through hole component insertion and soldering

- Lead time of 3-5 days for prototypes and 10-15 days for batches up to 1000 pcs

- More testing like flying probe testing and manual visual inspection

JLCPCB SMT Assembly Pricing and Costs

JLCPCB offers very competitive pricing for their SMT assembly service. Here are some of the key details on JLCPCB assembly pricing:

- NRE Tooling cost – This is a one time tooling fee charged for new designs and is $50 for 2-layer and $100 for 4-layer boards.

- Component costs – The total cost of the components is charged separately as per the bill of materials (BOM). Component prices are very reasonable and close to bulk component distributor rates.

- Assembly costs – The assembly charges start at $0.0017 per joint. Here is a breakup of assembly pricing:PCB QtyAssembly Cost per joint1-5$0.001710$0.001250$0.0007100$0.0005500$0.00041000$0.00022000$0.0001Notes:

- Price per joint decreases with higher quantities

- Assembly for quantities above 2000 pcs is quoted separately based on requirements.

- Shipping – Shipping rates for delivery via DHL, Fedex, UPS or air mail are charged separately based on quantity, weight and destination.

To summarize, the total cost is:

Tooling fee + Component cost + Assembly charges + Shipping

JLCPCB provides an online SMT pricing calculator where you can get an instant assembly quote by entering your PCB details.

Understanding JLCPCB’s SMT Assembly Capabilities

It is important to review the assembly capabilities and limitations before designing boards to be assembled by JLCPCB:

- Supported component sizes – 0201 to 25 x 25 mm SMT components can be assembled.

- High density PCBs – Boards with component density up to 0.4 mm pitch can be assembled reliably.

- BGA ICs – Ball grid array packages up to 17 x 17 mm with 0.5 mm pitch are supported.

- Passives – Chip resistors, capacitors, inductors, networks etc. in 0201 to 1206 case sizes can be used.

- Standard leaded components – SOIC, SOP, QFP, SSOP, TQFP and most common leaded package ICs are supported.

- Fine-pitch components – JLCPCB can assemble components down to 0.3mm pitch.

- Through hole support – Connectors, buttons, LEDs, potentiometers, heat sinks etc. can be assembled for SMT + TH service.

- PCB Technology – 2 to 8 layer boards with minimum hole size of 0.2mm and minimum track width/spacing of 4mil/4mil can be handled.

- Solder paste – Lead-free (RoHS compliant) solder paste is used.

- ESD Control – JLCPCB has ESD safe assembly environment as per J-STD-001 standards.

- Testing capabilities – AOI test, bar code scanning, flying probe test, manual inspection etc. lead to very low defect rates.

Limitations

- Large BGAs with pitch < 0.5mm are not supported currently.

- For RF boards with controlled impedance, consult JLCPCB first regarding capabilities.

- Extremely high component densities < 0.3mm pitch may have yield issues. Consult JLCPCB engineering first in such cases.

Step By Step Process of Using JLCPCB SMT Assembly

Here is an overview of the steps involved in using JLCPCB’s SMT assembly service for your PCB:

Step 1. Design your PCB based on JLCPCB’s assembly capabilities outlined above.

Step 2. Upload your Gerber files and BOM while ordering PCB fabrication at JLCPCB.com.

Step 3. Select “SMT Assembly” and choose Basic or SMT+TH assembly service.

Step 4. Upload your complete BOM and Centroid (XY location) file for assembly.

Step 5. JLCPCB will prepare an assembly quote based on your uploads. Review the quote and confirm order.

Step 6. Pay online via credit card, Paypal etc. NRE cost is added for first assembly order.

Step 7. JLCPCB will source all components listed in your BOM and proceed with SMT assembly as per the provided XY centroid locations.

Step 8. Assembled boards are then cleaned, inspected and tested as per JLCPCB’s quality process.

Step 9. Once assembly is completed, boards are shipped via DHL/Fedex to your address.

Step 10. Inspect PCBs on receiving to ensure proper assembly and quality. Provide feedback for any issues noted.

Following these steps correctly results in quick and problem-free assembly of your boards by JLCPCB’s SMT assembly lines.

JLCPCB SMT Assembly Lead Times

JLCPCB provides very fast turnaround for their assembly service considering the end-to-end process involved. Here are the standard lead times to expect:

Prototypes

- Basic SMT Assembly – 2 to 3 days

- SMT + TH Assembly – 3 to 5 days

Small batch

- Basic SMT Assembly – 7 to 9 days for up to 2000 pcs

- SMT + TH Assembly – 10 to 15 days for up to 1000 pcs

The above lead times are applicable once the order is confirmed after quote approval. It does not include the time required for preparing assembly quote which depends on your responsiveness to quote clarification requests from JLCPCB engineers.

JLCPCB also provides expedited build options to shrink the lead times further by 50% for additional charges.

For quantities above small-batch volumes, lead times are higher depending on specific requirements.

How to Design Your PCB for JLCPCB SMT Assembly?

Here are some tips for designing PCB assembly-friendly boards to avoid issues during JLCPCB’s SMT assembly process:

- Component Spacing – Maintain adequate clearance between components of at least 0.2mm. Higher clearance of 0.3 to 0.5mm is better.

- Component Orientation – All polarized components like diodes, ICs should be oriented in the same direction.

- Symmetric layout – Design component placement to be as symmetric and uniform as possible on both sides. Avoid irregular gaps.

- Bypass capacitors – Use bypass/decoupling capacitors for each IC to stabilize operation.

- Thermal reliefs – Add thermal reliefs for plane connections to avoid tombstoning issues.

- Component sizes – Use larger component sizes like 0603 and above for critical connections to avoid tombstoning or open solder joints with 0402 and 0201 sizes.

- Fine-pitch ICs – For ICs with lead pitch below 0.65mm, use exposed pad packages for better soldering yield.

- ESD protection – Use ESD protection devices on high-speed data lines to avoid ESD damage.

- Passive networks – Use passive resistor and capacitor networks instead of individual tiny components to simplify assembly.

By following these PCB design guidelines, you can ensure a smooth SMT assembly process and get the full benefits of JLCPCB’s professional assembly services.

How to Generate XY Centroid File for JLCPCB SMT Assembly?

The XY centroid file provides the exact XY co-ordinates for component placement on the PCB to guide JLCPCB’s SMT pick-and-place machines.

Here are some tips for generating the centroid file correctly for upload to JLCPCB during assembly order:

- Use your PCB CAD tool to output the XY coordinate data or centroid file. Most PCB design software like Eagle, Altium etc. have built-in utilities to do this.

- The file format should be Excel (.xls/.xlsx) or Notepad (.txt) file.

- The file should contain one line per component with RefDes, X and Y co-ordinates (in mm) separated by commas or tab spacing.

- The co-ordinates should match the CAD data and have at least 2 decimal places, for example R1,15.25,30.60

- The sequence of components in the file should match the component placement sequence used in PCB layout.

- No additional headers or text should be present.

Once you have the centroid file, upload it along with your BOM in JLCPCB SMT assembly order page. This provides necessary assembly data to JLCPCB.

SMT Assembly Quality and Reliability Offered by JLCPCB

JLCPCB’s SMT assembly lines have been audited and certified by third parties like UL for meeting IPC standards for assembly quality and reliability.

Some of the quality and reliability aspects to highlight:

- Low component defect rates with procurement controls and counterfeit component avoidance procedures.

- Automated optical inspection (AOI) to catch assembly defects followed by manual inspection.

- IPC Class 2 workmanship standards maintained.

- Testing via flying probe tester and bar code scanner system.

- ESD safe assembly environment and procedures.

- Analysis of defects data and continuous improvement of assembly processes.

- ISO 9001 and ISO 14001 certified manufacturing facilities.

JLCPCB is transparent about their assembly process and defect rates. They share detailed inspection reports and images from each inspection step for your review.

For new complex designs, JLCPCB’s engineering team provides design for manufacturing (DFM) analysis and recommendations to improve manufacturability and minimize assembly issues.

Frequently Asked Questions

Q1. What are the available options for ordering SMT assembly on PCBs ordered from JLCPCB?

Ans: There are 2 options – Basic SMT Assembly and SMT + Through Hole assembly. Basic SMT assembly mounts only surface mount components while SMT+TH assembly can mount SMT components and solder through-hole components as well.

Q2. Can I get assembled boards in small quantities like 5 or 10 pcs from JLCPCB?

Ans: Yes, JLCPCB offers SMT assembly even for prototype volumes as low as 5 boards. The only additional charge is the one time NRE (tooling) cost.

Q3. What component sizes and IC packages are supported by JLCPCB for SMT assembly?

Ans: JLCPCB supports component sizes from 0201 to 25mm x 25mm. This includes SOP, QFP, BGA and other standard IC package options up to 17x17mm, 0.5mm BGA pitch.

Q4. How do I share component centroid locations with JLCPCB for SMT assembly?

Ans: You can upload your component XY location centroid file in Excel or txt format. This file contains X,Y co-ordinates of all components from your PCB CAD tool.

Q5. Does JLCPCB procure all the components required for SMT assembly?

Ans: Yes, you only need to provide the component list and quantities in the BOM. JLCPCB sources all required components based on the BOM and assembles your boards.

Conclusion

JLCPCB’s SMT assembly service enables professionals and hobbyists alike to get high-quality assembled PCBs delivered to their doorstep. Their online-only automated assembly process makes it extremely convenient to get even complex designs assembled cost-effectively in small batches.

With its competitive pricing, quick turnaround times and reliable quality, JLCPCB SMT assembly is an attractive option for your next project. Their detailed online assembly order process and prompt support allows you to easily upload your gerbers, BOM and XY file to get an instant quote.

We recommend reviewing their assembly capabilities thoroughly and designing your boards accordingly to avoid issues. Following the PCB design guidelines outlined above is key. With some planning, you can easily leverage JLCPCB’s professional assembly services for faster product development.

0 Comments