Introduction

Printed circuit boards (PCBs) are essential components in most electronic devices we use today, from smartphones and laptops to medical equipment and cars. As PCBs become more complex and manufacturing moves overseas, many companies are looking for reliable and high-quality PCB assembly services close to home. This article will explore the key factors to consider when looking for PCB assembly near you and provide an overview of the PCB assembly process.

Benefits of Local PCB Assembly

Choosing a PCB assembly provider in your region or country offers several advantages:

Faster Turnaround Times

With suppliers located nearby, you can get prototype boards assembled and shipped more quickly. This speeds up the design verification and product development process.

Improved Communication

Direct and frequent communication with your PCB assembly partner enables real-time feedback and problem resolution. With vendors overseas, language barriers and time zone differences can hinder effective communication.

Reduced Shipping Costs

Less distance means lower shipping expenses and reduced risk of damage or delays for your high value PCB assemblies. This is especially important for quick-turn prototypes.

Better Quality Control

Overseas manufacturing limits the amount of quality control monitoring you can perform. Local partners allow product inspections, in-process checks, and tight collaboration to meet your quality standards.

Control Over Intellectual Property

Contract manufacturing overseas increases the risk of counterfeiting and IP theft. Working with trusted domestic PCB assembly services reduces this risk.

ITAR/Military Compliance

For defense and aerospace companies requiring ITAR and military spec compliance, using local PCB assembly services simplifies this process. Many foreign providers cannot meet ITAR restrictions.

Supporting Local Industry

Sourcing PCB assembly services locally retains skilled jobs, keeps supply chains robust, and builds relationships within your business community.

Capabilities to Look For

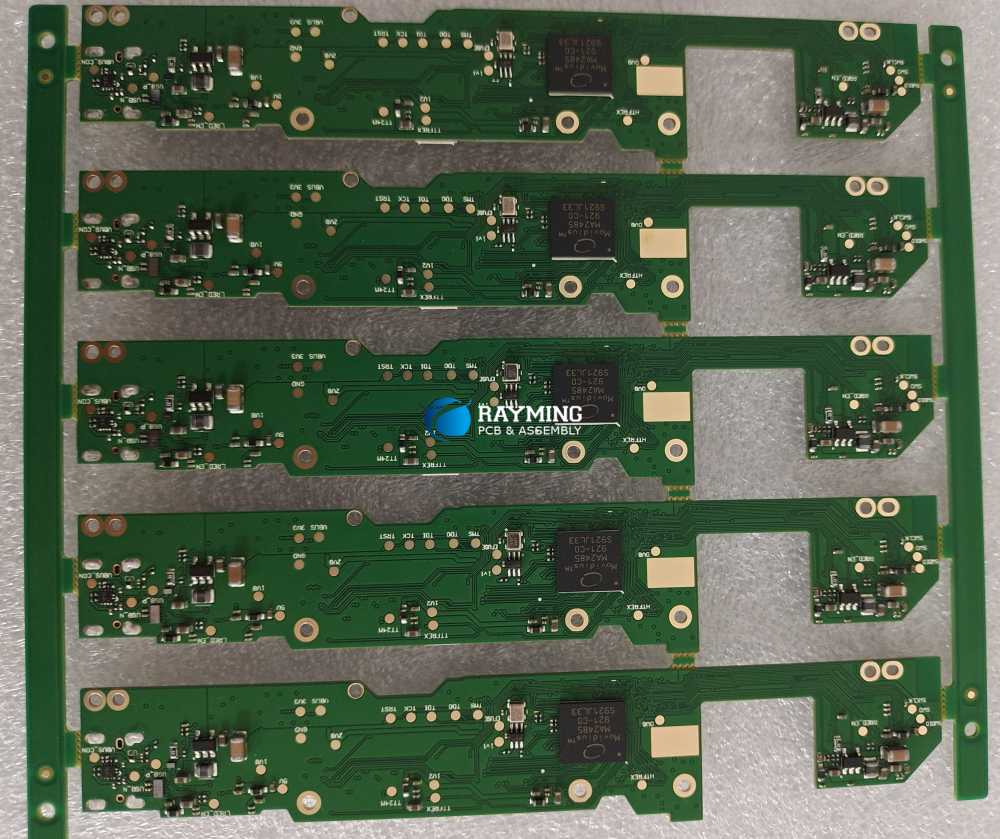

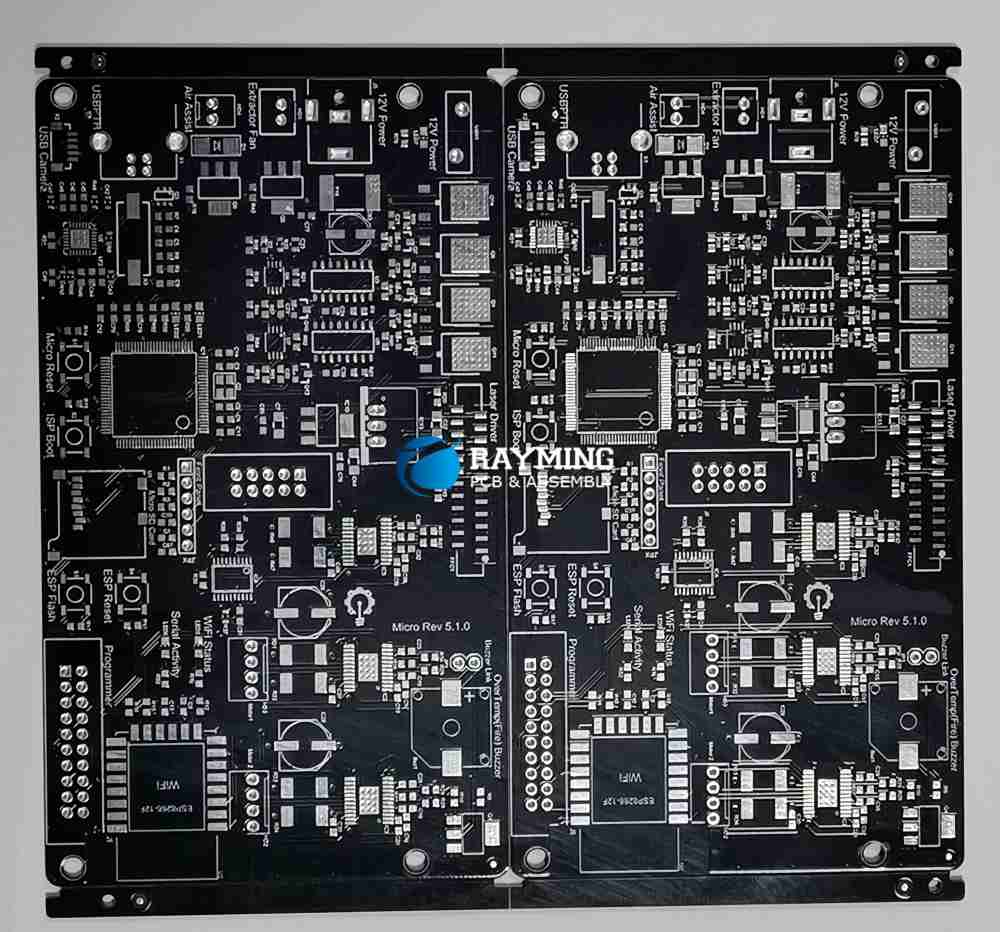

The PCB assembly process involves soldering surface-mount (SMT) and through-hole components onto printed circuit boards. Not all assembly shops offer the same set of capabilities. As you evaluate PCB assemblers in your area, consider these key competencies:

SMT Assembly

The provider should have experience with latest SMT placement equipment for high speed and high precision assembly of even ultra-fine pitch components. They should be able to work with BGAs, CSPs, QFNs, 0201 and 01005 discrete components.

Through Hole Assembly

Through hole components are still used on many PCBs. Check that the assembler can work with THDs from basic axial leads to fine pitch connectors and pins. This may require wave soldering or selective soldering processes.

Inspection and Testing

PCB assembly quality relies heavily on inspection. Confirm the provider has automated optical inspection (AOI) and X-ray capabilities to check for defects like poor solder joints, missing parts, or polarity issues.

Conformal Coating

A conformal coating adds a protective insulating layer to make assembled PCBs more resistant to moisture, dust, chemicals or temperature extremes. Verify whether they offer conformal coating services.

Box Build Assembly

Many products require integration of a fully assembled PCB into an enclosure along with cables, connectors and other hardware. Choose an assembler experienced in box builds for a complete packaged product.

Supply Chain Management

The best PCB assembly partners can not only assemble your boards, but can also procure components through established global distribution channels. This simplifies your BOM sourcing process.

Design for Manufacturing (DFM)

Early DFM analysis can identify any component selection, placement or routing issues that would adversely affect manufacturability. Partner with an assembler that provides DFM input during the design phase.

Flexible and Scalable Capacity

Whether you need a few prototype boards urgently assembled or a high volume production run, look for assemblers that can scale to meet your needs and timeframes.

Responsiveness and Communication

From quote to delivery, the provider should offer transparency, quickly respond to inquiries, and proactively provide updates. Check reviews and talk to past customers on their responsiveness.

The PCB Assembly Process Step-by-Step

Understanding the stages involved in assembling a PCB will help you know what to expect when partnering with a PCB assembly service. Here is an overview of a typical PCB assembly process workflow:

1. Design Files

The assembly process starts when you provide the PCB fabrication and assembly drawings, Gerber files, bill of materials (BOM), assembly drawings, and any other specifications. These define your PCB design and components required.

2. Documentation Reviews

The assembler’s engineers will review your design files and documentation to ensure they can meet all specifications before providing a cost estimate and production timeline. They may make recommendations if they notice any red flags.

3. Prototyping

For many projects, you’ll want prototypes assembled first to validate the design before full production. Prototyping provides an early look at the PCBs and can reveal any errors needing correction.

4. NPI (New Product Introduction)

During this stage, the assembly partner creates work instructions, programs the component placement machines, procures necessary parts, and sets up the production line for your PCB assembly process.

5. SMT Assembly

SMT (surface mount technology) components are accurately placed onto the PCBs by automated pick-and-place machines. This step is critical for achieving proper alignment and contacts. The boards then pass through a reflow oven to melt solder paste and permanently attach the SMT parts.

Through hole components are inserted and soldered, either manually or via automated equipment. Wave soldering can solder dozens of THDs simultaneously. For selective soldering, a mini-wave tool solders specific THDs.

7. Conformal Coating

A protective coating may be selectively applied over certain areas of the assembled PCBs, covering them in a thin lacquer layer against environmental risks. Conformal coating is optional.

8. AOI Inspection

Automated optical inspection (AOI) rapidly scans each completed board to check for missing, misaligned or faulty components, helping catch any defects early.

9. Additional Assembly

If the project includes any additional assembly requirements such as power supplies, connectors, harnesses or hardware, these items are integrated with the PCB assembly during box build.

10. Final Testing and Inspection

Whether done manually or using automated test equipment, this verification validates that the populated PCBs function as intended before shipment. Testing may include flying probe, boundary scan, continuity or functional tests.

11. Delivery

The finished PCB assemblies are packed and shipped according to your requested method – usually standard overnight or second day air freight for prototypes or bulk shipment for production orders.

Factors That Determine PCB Assembly Costs

What will it cost to have your printed circuit boards assembled? PCB assembly pricing depends on several primary factors:

- Board complexity – Simple PCBs with lower component counts and easier assembly can be cheaper than complex boards requiring advanced processes. High density designs raise costs.

- Board size – Smaller PCB assemblies incur lower material expenses while large boards use more supplies, increasing costs. Panelizing multiple smaller PCBs together can save costs.

- Component types – Basic through-hole parts are simple and inexpensive to assemble compared exotic SMT components in ultra-fine pitches. BGAs, 0201 discretes and connectors add cost.

- Assembly volume – Prototyping rates for low initial quantity are higher per board. Assembly pricing drops significantly at production volumes due to economies of scale.

- Special requirements – Addition of conformal coating, box build enclosures or electrical testing during assembly increases costs. Rework of defective boards also adds cost.

- Location – Where the PCB assembler is located impacts their labor rates and overall operating costs. Nearshore regions can offer lower costs than local assembly.

Understanding these cost drivers will help you select the most economical PCB assembly source that meets your quality requirements. Be sure to get quotes from multiple assemblers.

Top 5 PCB Assembly Companies Near Me

To give you a head start on your supplier search, here are 5 leading PCB assembly providers located throughout the US:

1. EIT

Locations: Massachusetts, New Hampshire, New York, California

EIT offers advanced SMT, THD and box build assembly serving a range of industries. They are known for quick-turn prototyping and production ramps.

2. Sierra Circuits

Locations: California, Oregon, Washington

Sierra Circuits provides fully-integrated PCB services including fabrication, assembly through their Sierra Assembly division, and testing. They specialize in HDI, flex/rigid-flex PCBs.

3. PulseForge

Location: Oregon

PulseForge focuses on prototype through mid-volume PCB assembly catering to startups and engineers needing fast turnarounds and crisp communication.

4. Sunstone Circuits

Location: Oregon

Sunstone delivers same-day PCB assembly for prototypes with online instant quoting. They also support start-to-finish product development through NPI and pilot runs.

5. Screaming Circuits

Location: Arizona

From simple assemblies to complex, high-mix, low-volume, Screaming Circuits offers quick-turn assembly services even for rigid-flex PCBs. They promise 1-3 day assembly.

This list provides a starting point, but there are many other reputable PCB assembly providers servicing local regions nationwide. With research, referrals and quotes, you can find the right partner meeting your specific needs, lead times and budget.

Frequently Asked Questions

What are the typical lead times for PCB assembly near me?

For prototype quantities needing quick-turn service, expect assembly lead times between 1-5 days from most domestic PCB assemblers. Production runs may ship within 2-4 weeks after initial setup.

Can I get PCBs assembled in the US if they are fabricated offshore?

Absolutely. Many customers design boards overseas to save on fabrication costs, then ship them to US-based assemblers to get product to market faster.

How should I package my boards when shipping for assembly?

PCBs are fragile, so packaging them between rigid sheets in a sturdy box prevents damage during shipment to your assembly partner. Use ESD safe bags as well.

Does my BOM need to be in a specific format?

While assemblers can work with XLS or CSV bills of materials, it helps to format your BOM using guidelines from your assembly partner so component data is consistent.

Should I choose an assembler close to my location?

Proximity allows visiting your PCB assembler to audit processes and quality if desired. However, choosing the right match for capabilities and responsiveness is more important than distance.

Conclusion

As PCB assembly technology evolves and shifts overseas, identifying the right domestic assembly partner has become a critical decision. Local providers offer rapid prototyping, superior communication, ITAR compliance and complete product assembly services. By selecting an assembler with the right set of competencies, capacity and quality focus, you gain a valuable extension to your team that accelerates time-to-market and minimizes risks. Use these guidelines to find the best provider for your next PCB assembly project, no matter the complexity.

0 Comments