Turnkey printed circuit board (PCB) assembly refers to outsourcing the entire production process of assembling electronic circuits on PCBs. A turnkey assembly service provider handles all stages – from sourcing components to soldering to final testing and inspection. This allows companies to focus on their core competencies like design and engineering rather than manufacturing.

In this comprehensive guide, we will explore what turnkey PCB assembly entails, its benefits, how to choose the right assembly partner, key considerations, and more.

What is Turnkey PCB Assembly?

A turnkey PCB assembly process typically includes the following stages handled by the assembly company:

Sourcing and Procurement

- Obtaining all required components like ICs, resistors, capacitors etc. as per bill of materials (BOM)

- Managing inventory, minimizing shortages and delays

- Vendor selection and coordination

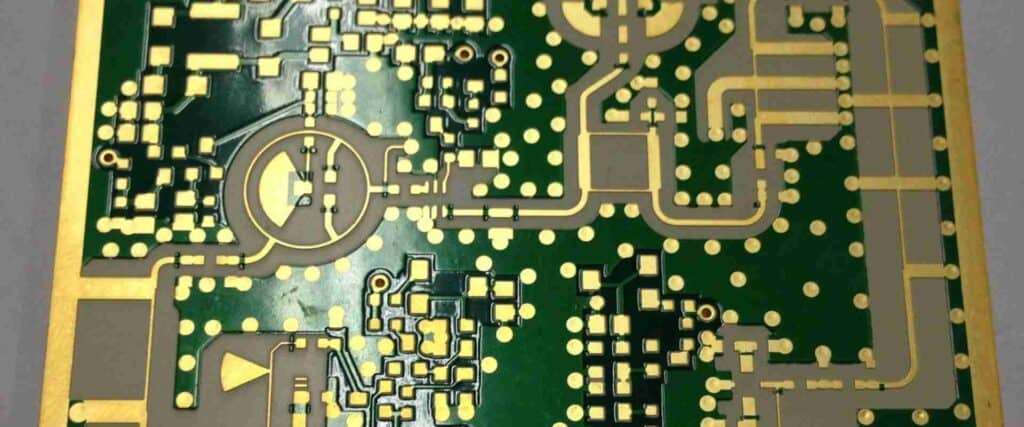

PCB Fabrication

- Producing blank PCBs from client’s Gerber files

- Ensuring quality standards in PCB fabrication

Solder Paste Printing

- Precision application of solder paste on PCBs before component placement

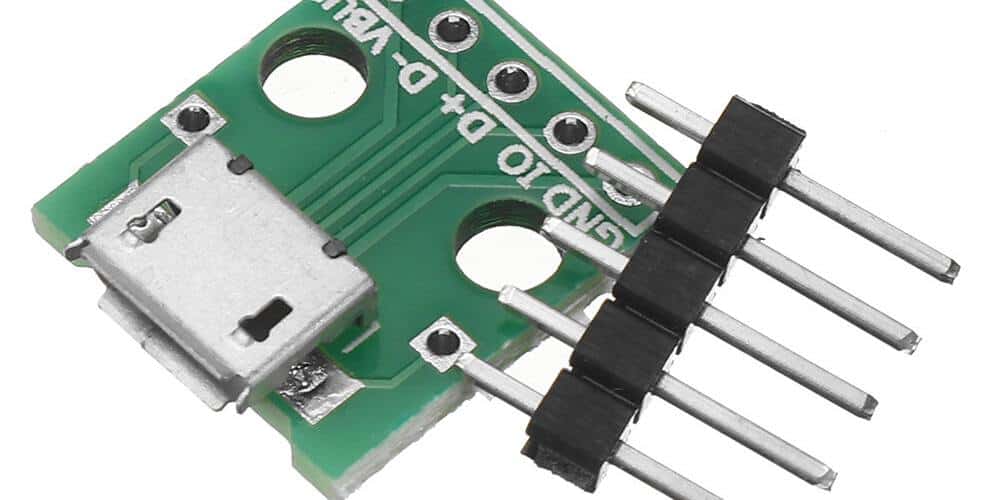

Pick and Place Assembly

- Mounting all components on boards using pick and place machines

Reflow Soldering

- Soldering components to attach them securely to boards by heating entire assembly

Conformal Coating

- Applying protective material over assemblies for insulation and prevention of corrosion

Testing and Inspection

- Visual inspection and microscopy examination to detect defects

- Testing functionality using fixtures according to specifications

- Programming firmware and loading software (if required)

Packaging and Delivery

- Cleaning and packing finished boards in anti-static bags or containers

- Shipping assembled PCBs to the customer

This comprehensive service allows companies to outsource their entire assembly needs and receive fully tested boards ready for application. Assembly houses have the capabilities, supply chains and economies of scale that makes this process efficient.

Benefits of Turnkey PCB Assembly

Here are some of the main advantages of outsourcing turnkey assembly services:

Focus on Core Expertise

Electronics companies can channel their resources into design, product development and IP creation rather than diverting efforts into manufacturing operations.

Access to Advanced Assembly Infrastructure

Well-equipped assembly facilities have sophisticated machinery like automated pick and place, AOI, and complex soldering tools. Outsourcing gives access to such capital intensive equipment.

Skilled Technical Expertise

Reputable assembly partners have experienced engineering teams with assembly process knowledge required to build boards efficiently. Their technical capabilities are hard to replicate in-house.

Faster Time to Market

The parallel manufacturing capabilities of assembly houses reduces production times allowing faster time to market for new products.

Cost Savings

Outsourcing assembly minimizes capital expenditure and provides economies of scale leading to lower per unit costs. It converts fixed costs into variable costs.

Quality and Compliance

Reliable assembly partners maintain strict quality controls and compliance to IPC standards, ISO certifications etc. This results in lower defects and field failures.

Flexible and Scalable Capacity

Working with an assembly partner provides flexibility to ramp production up and down based on demand without having to maintain fixed internal capacity.

Clearly, the benefits of turnkey PCB assembly for OEMs and other electronics companies are substantial. The key lies in selecting the right partner.

How to Select a PCB Assembly Partner

Here are some crucial factors to consider when selecting a turnkey assembly service provider:

Technical Capabilities

Examine their assembly process capabilities across the production stages outlined earlier. Review machinery, facility, capacity, expertise levels, certifications etc.

Quality Systems

Evaluate their quality control procedures, adherence to standards, defect rates, quality certifications (ISO9001, IPC-A-610), and documentation.

Design Support

Many good assemblers provide value-added services like design for manufacturing (DFM) reviews, BOM optimization, technical documentation etc.

Supply Chain Capability

Assess sourcing bandwidth, vendor network, inventory management systems, and supply continuity record during shortages.

Customer Service

Responsiveness to queries, support during new product introduction (NPI), and issue resolution processes determine overall experience.

Location and Logistics

Proximity of production facility, warehousing, and shipping options should match distribution needs and enable timely delivery.

Pricing and MOQs

Compare assembly pricing, minimum order quantities (MOQs), and tooling/setup charges. Get detailed quotations.

Verifying Assembler Credentials

Check company track record, client references, management expertise, and financial stability before outsourcing high-value production.

By carefully evaluating PCB assemblers on these key aspects, product companies can find the ideal partner for their specific outsourcing needs and long term relationship.

Key Considerations for Effective PCB Assembly

To ensure a smooth turnkey assembly process and end product quality, OEMs must provide certain inputs and preparation:

Complete BOM and Component Details

- Supplier part numbers, reference designators, tolerance, ratings etc should be comprehensive

Gerber Files

- Ensure Gerber files are complete, validated, and according to assembly partner’s requirements

Design for Manufacturability

- Board layouts must optimize ease of assembly, testability, thermal dissipation etc.

Compliance Requirements

- Clearly specify regulatory (UL, CE, FCC etc.) and customer compliance needs in advance

Test Specifications

- Provide detailed test parameters, procedures, fixtures, programming files and acceptance criteria

Quality Expectations

- Establish quality benchmarks, failure thresholds, acceptable defect levels, and RMA criteria

IP Protection

- Execute NDA contracts and take measures to protect intellectual property and proprietary information

Designating Contact Person

- Maintain continuous interaction with designated account manager at assembly house

With the right preparations, expectations alignment, and partnership approach, electronics companies can maximize the benefits of outsourced turnkey PCB assembly.

Types of Turnkey Assembly Services Offered

Reputable PCB assembly service providers offer a range of capabilities to meet diverse product requirements:

Prototype Assembly

Building small-batch prototypes for evaluation before full production. Useful for proof-of-concept and testing.

Low-Volume Production

Assembly batches between prototype and high-volume (under 500-2000 units). Targeted at startups and new product launches.

Medium-Volume Production

For established products with expanding demand (up to ~10,000 units). Provides flexibility.

High-Volume Production

Mass production assembly of 100,000+ boards per month. Caters to mature, stable products.

In addition, some advanced assembly services include:

- Double-sided and multilayer PCBs

- Fine pitch/ultra-fine pitch components

- BGAs, COB, and advanced packaging

- DFM/DFT/AOI optimization

- Function testing and burn-in

- Box build and product integration

- Supply chain/logistics solutions

This range of assembly types enables electronics innovators to find services tailored for every stage of their product life cycle.

Global Turnkey Assembly Markets and Trends

The global PCB assembly market size was valued at USD 27.2 billion in 2022. Some key aspects shaping the technology and business landscape:

Asia’s Dominance

Asia accounts for over 90% of global electronics assembly output due to low-cost skilled labor, established supply chains, favorable policies, and enormous domestic demand. China alone produces over 50% of the world’s consumer electronics.

Impact of COVID-19

The pandemic resulted in heightened demand for critical medical devices and tele-health equipment. At the same time, it created component sourcing challenges that disrupted global supply chains. This highlighted the need for diversification and nearshoring.

Growth in High-Density PCBs

As electronics devices get more compact and powerful, demand has risen for multilayer PCBs, HDI boards, flex/rigid-flex boards, and substrates for IC packages. This requires advanced assembly techniques.

Miniaturization Trend

Miniaturized circuits are increasing assembly challenges due to fine features, smaller connectors, higher I/O density. Technology innovations in fabrication and precision placement are crucial for reliable assembly.

Automation Uptake

With rising focus on quality and precision along with skilled labor shortages, automated assembly lines using robotic arms, pick and place and AOI are being deployed widely.

Supply Chain Visibility

Data-driven software tools provide real-time visibility into orders, inventory, costs, production monitoring, and supply chain tracking for optimized assembly management.

Environmental Regulations

Green manufacturing standards for material toxicity, e-waste, and recycling oblige assembly houses to adopt more sustainable processes and reduce carbon footprint.

Conclusion

The accelerating pace of electronics innovation and connectivity is driving up demand for advanced PCB assemblies manufactured efficiently at scale. Turnkey assembly outsourcing provides an optimal solution through proven benefits like reduced costs, faster delivery, rapid scalability and high quality.

By selecting the right assembly partner with rigorous vendor assessments across technical and supply chain capabilities, customer focus, quality systems and global footprint, product companies can leverage outsourcing to shorten time-to-market and focus intensely on design development.

With its vast infrastructure and low-cost skilled workforce, Asia remains central to global PCB assembly, but supply chain diversification along with process automation and digitization are imperative to tackle future disruptions. As long as electronics continue to advance, professional assembly houses will play an indispensable role in translating their customers’ visions into functioning reality.

h2: Frequently Asked Questions

h3: What are the key stages in a turnkey PCB assembly process?

The main steps in end-to-end turnkey assembly are:

- Sourcing components

- PCB fabrication

- Solder paste printing

- Pick and place assembly

- Reflow soldering

- Conformal coating

- Testing and inspection

- Packing and shipping

h3: What are the main advantages of outsourcing PCB assembly?

Outsourcing provides benefits like:

- Access to advanced manufacturing infrastructure

- Focus on core competencies rather than manufacturing

- Faster time to market for new products

- Cost savings through economies of scale

- High and consistent quality

- Production flexibility and scalability

h3: What does design for manufacturability (DFM) mean in PCB assembly?

DFM refers to designing boards by optimizing placement, spacing, orientations, etc. to make assembly straightforward and minimize errors. For example, providing enough clearance between components for pick and place equipment and positioning parts consistently across assemblies.

h3: What inspection techniques are used to ensure quality in PCB assembly?

Common inspection methods include:

- Visual inspection under microscope

- In-circuit testing (ICT) to verify shorts, opens, etc.

- X-ray imaging to check hidden joints

- Optical/automated optical inspection (AOI)

- Coordinate measuring machines (CMMs)

- Flying probe testing

- Boundary scan testing for components and boards

h3: Why is process automation becoming more important in PCB assembly?

Automation improves assembly speed, precision, defect reduction and overall productivity. Cobots, automated soldering, automated optical inspection and other Industry 4.0 technologies enable reliable high-volume production, make processes leaner and compensate for labor shortages.

0 Comments