Introduction

Developing a new electronic product requires assembling prototypes to test form, fit, and functionality before going to production. However, assembling even a simple PCB withmodern components using the latest techniques requires skill, experience, and specialized equipment. For low to medium complexity designs, partnering with a prototype electronics assembly service makes sense so you can focus on design iterations rather than acquiring assembly capabilities in-house. This guide covers key considerations when choosing an electronics assembly provider for prototyping and tips to ensure high-quality builds.

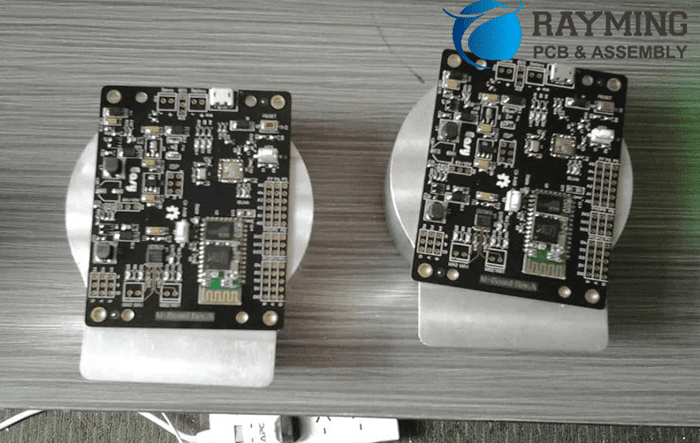

Overview of Prototype Assembly Process

Prototype PCB assembly transforms a bare PCB into a functional electronic circuit by soldering and assembling components. The main steps include:

SMT Assembly

Surface mount components like ICs, resistors, and capacitors are mounted by solder paste printing, pick and place, and reflow soldering:

| SMT Assembly Steps | Description |

|---|---|

| Solder Paste Printing | Apply solder paste on PCB pads |

| Component Placement | Use pick and place machine to position components on pads |

| Reflow Soldering | Heat PCB in oven to melt solder and attach components |

Through-Hole Assembly

Larger through-hole parts are inserted into holes in the PCB and soldered:

| Through-Hole Assembly Steps | Description |

|---|---|

| Component Insertion | Insert leads through corresponding PCB holes |

| Soldering | Solder joints to mechanically attach components |

Post-Solder Processing

Cleaning, inspection, and testing help ensure quality:

- Flux Cleaning – Remove residues after soldering

- AOI Inspection – Detect defects using automated optical inspection

- Testing – Validate boards meet functional requirements

Choosing a Prototype Assembly Provider

Factors to consider when selecting an electronics assembly service:

Technical Capabilities

- Experience with complex board assembly – fine pitch, BGAs, high density

- Range of assembly expertise – SMT, through-hole, double-sided, multilayer

- Inspection tools – x-ray, AOI, flying probe

- Component sourcing services

Quality Processes

- Assembly workmanship standards – IPC-A-610, J-STD-001

- Process controls and operator training

- Traceability of components and materials

Turnaround Time

- Lead time for assembly – select fastest option for prototyping

- Domestic vs international options

- Inventory levels for quick-turn requirements

Reliability and Reviews

- Tenure in industry

- Past customer reviews and satisfaction

- Results delivering on quality, lead time, and service

Pricing

- NREs, component costs, and assembly rates

- Potential rework costs if defects occur

- Value compared to capabilities and deliverables

Best Practices for Prototype Assembly

Follow these tips to help ensure you receive high-quality assembled prototypes:

Engage Early for DFM Analysis

Have assembler review design and bill of materials for potential issues early.

Provide Detailed Documentation

Supply complete assembly drawings, schematics, BOM, Gerbers, netlist, etc.

Use Assembler’s Component Library

Leverages existing approved parts list to minimize errors.

Request Test Coupons

First article assemblies validate process before full prototype build.

Perform In-Circuit and Functional Testing

Thoroughly test prototypes to confirm operation and catch faults.

Request Safety Testing for Certifications

For products requiring safety marks like UL, CE.

Managing Costs

Ways to help reduce prototype assembly expenses:

Standardize Components

Use common resistor/capacitor sizes, standard connectors etc.

Consolidate Parts

Minimize unique components to simplify bill of materials.

Provide Long Lead Items

Supplying hard-to-source parts helps reduce procurement time/cost.

Reuse Fixtures

Repeatedly using same test fixtures across builds lowers cost.

Share Gerber Files

If only minor revisions, tweaking existing data saves time.

Compare Multiple Assemblers

Shop different assemblers for best price on specific build.

Example Prototype Assembly Quote

Below is a sample quote for assembling 10 prototypes of a mixed technology board:

| Parameter | Details |

|---|---|

| PCB Size | 6″ x 4″ |

| Layer Count | 4 layer |

| Technology | SMT and Through Hole |

| Components<br>- SMT | 300 parts<br>- 0402-5050 packages |

| -Through Hole | 5 connectors, 20 discrete parts |

| Lead Time | 6 days |

| Description | Cost Per Board |

|---|---|

| PCB Fabrication | $130 |

| SMT Assembly | $200 |

| Through Hole Assembly | $55 |

| Component Costs | $100 |

| Solder Paste, Hardware | $20 |

| Total Cost | $505 |

For low volume, assembly represents about 40% of total cost. Components are also a significant portion.

Frequently Asked Questions

Here are answers to some common questions about prototype electronics assembly:

Q: What are the key data deliverables needed for assembly?

Gerber files, bill of materials, assembly drawings, component datasheets, netlist, any special instructions.

Q: How long does prototype assembly normally take?

With most assemblers, lead time can range from 2 days up to 2 weeks depending on complexity.

Q: What are common causes for delays during prototyping?

Part shortages, long component lead times, insufficient design information, quality issues requiring rework.

Q: What factors lead to higher/lower assembly costs?

Component types/quantities, board size, layer count, manufacturing tolerances all impact cost.

Q: What testing services should be used?

Electrical testing, in-circuit test, functional test at a minimum to validate a working prototype.

0 Comments