Introduction

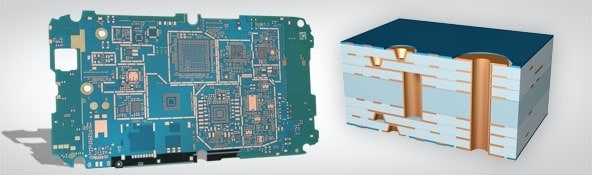

Printed circuit boards (PCBs) are essential components in almost every electronic device. As products become more complex, PCBs have evolved to enable more functionality through more layers, smaller traces, and components with finer pitch. This progression means that assembling PCB prototypes now requires specialized skills, equipment, and processes to ensure quality and reliability. This guide will explore what PCB prototype assembly entails, key considerations when choosing an assembly service, and tips for getting the best results.

Overview of PCB Prototype Assembly Process

PCB assembly, also known as PCBA (Printed Circuit Board Assembly), involves soldering and assembling electronic components onto a PCB. The main steps include:

SMT Assembly

Surface mount technology (SMT) components are soldered on one or both sides of the PCB using solder paste and a reflow oven. Common SMT components include:

- Resistors, capacitors, and inductors

- Integrated circuits (ICs)

- Connectors

- LEDs

| SMT Assembly Steps | |

|---|---|

| Solder Paste Screen Printing | Apply solder paste on PCB pads |

| SMT Component Placement | Place components on pads with solder paste |

| Reflow Soldering | Heat PCB to melt solder and attach components |

Through-Hole Assembly

Through-hole components have leads that go through holes in the PCB and are soldered on the opposite side. This includes connectors, transformers, heat sinks, etc.

| Through-Hole Assembly Steps | |

|---|---|

| Component Insertion | Insert component leads through PCB holes |

| Soldering | Solder joints to attach components |

Post-Solder Processing

Additional steps help ensure quality:

- Cleaning: Remove flux residue from soldering

- AOI Inspection: Automated optical inspection to check for defects

- Testing: Validate circuit functionality

Conformal Coating

A protective coating can be applied to resist moisture, dust, chemicals.

Choosing a PCB Assembly Service Provider

Here are key factors to consider when selecting a prototype PCB assembly service:

Capability

- Experience with complex PCBs – fine pitch components, high density, smaller components

- Range of assembly capabilities – SMT, through-hole, mixed technology, double-sided, multi-layer PCBs

- Component sourcing services available

- Processes for quality and error prevention

Turnaround Time

- Lead time can range from 2-10 days for assembly

- Choose supplier with fastest turnaround for prototyping stage

Quality

- Quality certifications – ISO 9001, IPC standards

- Use of inspection methods like x-ray, AOI, testing

- Process controls and operator training

Pricing

- Evaluate total costs – NREs, component costs, assembly charges per unit

- Consider potential rework costs if quality issues arise

Customer Service

- Responsive sales and engineering support

- Communication during assembly process

- Help resolving production issues

How to Get High-Quality PCB Assemblies

Follow these guidelines for best results when using a PCB prototype assembly service:

Provide Complete Design Data

Supply Gerber files, bill of materials, assembly drawings, and documentation so the assembler has all needed info.

Use An Assembler’s Component Library

Take advantage of existing component data to minimize errors and speed up assembly.

Request Pre-Production Samples

Have a small batch assembled first to check assembly process and catch errors early.

Perform Design For Manufacturing (DFM) Review

Ask assembler to audit design for potential issues before full production.

Specify Test Requirements

Indicate any testing or inspection needed to ensure boards function as intended.

Cost Optimization Tips

Ways to help reduce prototype assembly costs:

Choose Standard Component Packages

Opt for sizes like 0603, 0402 that assemblers regularly work with.

Minimize Component Types

Reduce unique parts to simplify bill of materials and procurement.

Consolidate Connectors

Use common connectors for interfaces to avoid sourcing many custom types.

Provide Component Samples

Supplying parts upfront can lower procurement costs for assembler.

Stencil Tolerance to 0.1mm

Finer solder paste alignment can improve yields with ultra-fine pitch.

Share Test Fixtures

Reusing fixtures across builds decreases test setup costs.

Example Assembly Price Breakdown

Here is an estimate for assembling 10 prototypes of a complex PCB with the following characteristics:

- PCB Size: 160mm x 100mm

- Layer Count: 6

- Components:

- SMT: 375 including BGA, QFN, 0402 discrete

- Through-Hole: 25 including connectors, switches, pots

- Lead Time: 5 days standard

| Description | Cost Per Board |

|---|---|

| PCB Fabrication | $200 |

| Stencil | $130 |

| SMT Assembly | $145 |

| TH Assembly | $55 |

| Component Costs | $125 |

| Solder Paste, Hardware | $15 |

| Total Cost | $670 |

For this board, the assembly cost represents about 33% of the total prototype cost. Component costs are also a significant factor.

Frequently Asked Questions

Here are answers to some common questions about PCB prototype assembly services:

Q: Can I provide my own components to lower costs?

Yes, you can supply components to an assembler, known as “customer supplied components”. This helps reduce procurement costs, but you’ll need to provide all reels/cut tapes and verify component quality.

Q: What data do I need to provide for assembly?

You’ll need Gerber, drill, and netlist files for the PCB fabrication. For assembly, provide a complete bill of materials, assembly/placement drawings, and any special instructions.

Q: How are components sourced by assembly services?

Reputable assemblers use authorized distributors or the component manufacturers directly when procuring parts to ensure authentic, high-quality components.

Q: What is the best assembly service for low volume prototypes?

For under 10 boards, small local prototype shops are ideal for low volume, high mix, fast assembly to validate designs early.

Q: What is a DFM review and why is it important?

Having an assembler do an early design for manufacturing review helps find issues in the schematics or layout that could impact manufacturability or quality before full production.

0 Comments