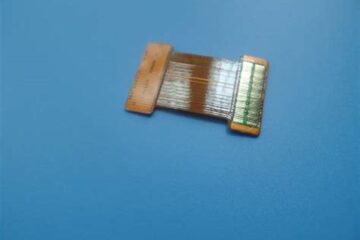

PCBA

Battery Backup Circuit: A Comprehensive Guide in Making One

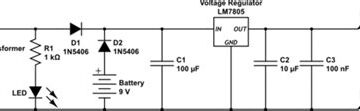

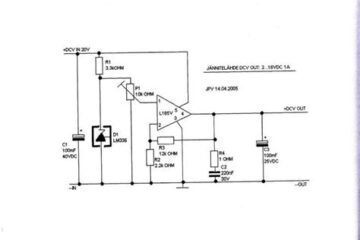

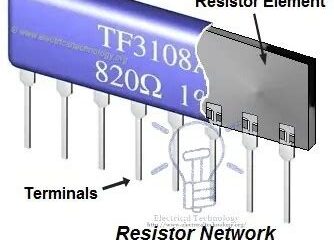

Introduction to Battery Backup Circuits A battery backup circuit is an essential component in many electronic devices, ensuring uninterrupted power supply during power outages or when the main power source fails. This comprehensive guide will walk you through the process of creating a reliable and efficient battery backup circuit, covering everything from the basic concepts to the practical implementation. What is a Battery Backup Circuit? A battery backup circuit is a system that automatically switches Read more…