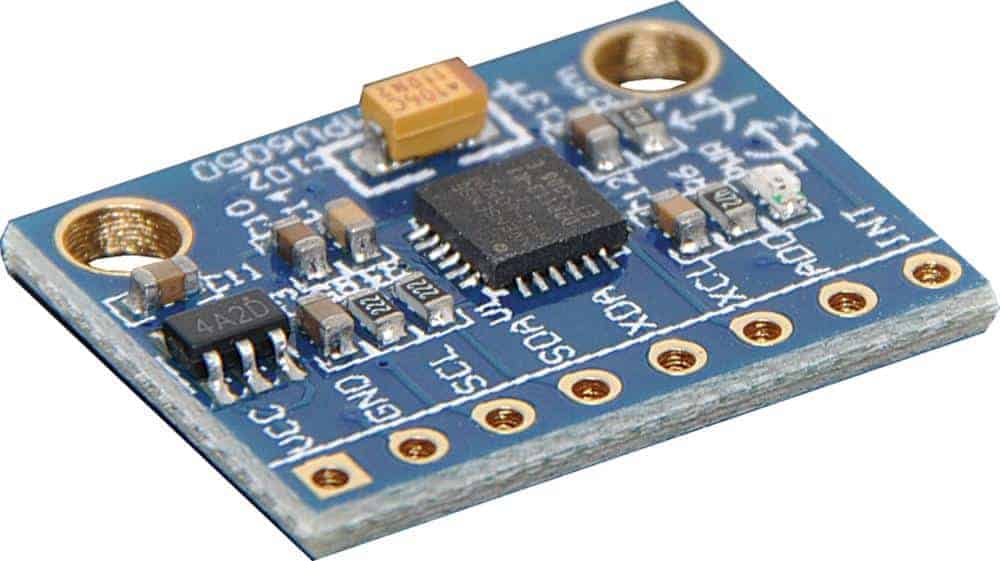

Printed circuit boards (PCBs) are essential components in nearly all modern electronic devices. They provide the base for mounting and connecting electronic components using conductive copper traces etched from copper sheets laminated onto a non-conductive substrate. PCBs come in a variety of materials, sizes and complexities. The more complex the board, the higher the cost to manufacture it through a process called PCB assembly. However, for those on a budget, there are ways to get high quality PCBs assembled at low cost. Here’s what you need to know.

What is PCB Assembly?

PCB assembly is the process of soldering electronic components onto a PCB. This involves:

- Placing components in their designated spots on the board.

- Soldering the leads or terminals to the copper traces to form an electrical connection.

- Trimming excess lead wires.

- Testing for manufacturing defects.

- Additional steps like conformal coating.

This is usually done automatically by pick-and-place machines and reflow ovens in a process called surface mount technology (SMT). However, very small quantity boards can be assembled manually. The more complex the board and tighter the tolerances, the more expensive the assembly process.

Cost Factors in PCB Assembly

Several factors determine the cost of professionally assembling PCBs:

1. Board Complexity

The more complex the board, the more expensive it is to assemble. Complexity factors include:

- Board size – Bigger boards cost more.

- Component count – More components means higher cost.

- Component types – Fine pitch and BGA components cost more than through-hole parts.

- Layer count – Additional layers in multilayer boards add cost.

- Board density – Densely packed boards are more expensive.

- Tolerances – Tighter tolerances require more precise manufacturing.

- Special processes – Processes like solder masking, via filling, etc. add cost.

2. Quantity

Because PCB assembly lines have high setup costs, smaller quantities cost exponentially more per board. The cost drops significantly at quantities of 100+ boards.

3. Assembly Type

Fully assembled boards (with all components soldered) cost more than partially assembled or bare PCBs (no components assembled).

4. Lead Times

Normal lead times of 2-4 weeks allow manufacturers to balance production efficiently and charge less. Rush orders incur higher costs for expedited processing.

5. Location

PCB assembly pricing varies based on where in the world the assembly is done. Developing countries generally have lower labor costs so assembly is cheaper there.

Tips for Low Cost PCB Assembly

Here are some tips for getting your PCBs professionally assembled at lower costs:

1. Choose Standard Components Whenever Possible

Opt for common through-hole and surface mount components that manufacturers have in stock rather than expensive, custom parts. This avoids component procurement fees.

2. Design for Ease of Assembly

Avoid densely packed boards and include design tolerances that aren’t too tight. Use solder masking and silkscreen to indicate component placements clearly. This streamlines assembly.

3. Order Larger Quantities

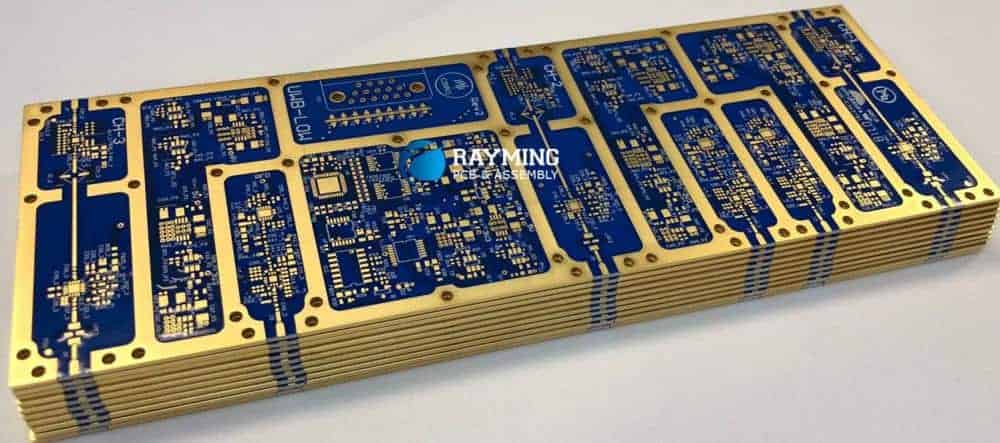

Order at least 100 boards for the best economy of scale. If the budget is tight, consider panelizing (combining multiple smaller boards onto one large panel) to reach 100 boards total.

4. Use an Online Instant Quote Service

Services like PCBWay and JLCPCB offer automated instant PCB assembly quotes based on your uploaded files. This lets you easily compare prices.

5. Choose a Developing Country Assembly Partner

Partners in China, Southeast Asia offer lower labor costs than American or European companies. Just ensure they follow quality standards.

6. Standardize on One PCB Manufacturer

Sticking with one reliable manufacturer avoids extra costs when switching between different fab and assembly partners.

7. Order Bare PCBs Separately

For prototype testing, order bare PCBs first. This avoids paying for soldering untested boards. Only order assembled boards once the design is validated.

8. Provide All Needed Design Files

Supply assembly partners with complete BOMs, centroid files, pick-and-place files, etc. to avoid errors or delays.

Top Low Cost PCB Assembly Services

Here are some reputable low cost PCB assembly providers to consider:

| Company | Location | Notes |

|---|---|---|

| JLCPCB | China | Ultra low cost service starting at $2/sq. in., $0.0017 components. |

| PCBWay | China | Low cost, fast turnaround. Prices from $28 for 10 boards. |

| Seeed Studio | China | Low volume specialist. Full assembly from $66.70 for 5 boards. |

| ALLPCB | China | $33 assembly quote for 10 simple boards. Multiple assembly options. |

| Elecrow | China | Specializes in prototyping. Volume pricing from $2.5/board. |

| PCBCart | USA | Low minimum orders (10 boards). 24 hour rush service. |

| Sierra Circuits | USA | High quality domestic PCB assembly with online quotes. |

FQA

What is the cheapest PCB assembly service?

JLCPCB offers some of the lowest cost PCB assembly starting at just $2/square inch of board space and $0.0017 per component. The tradeoff is longer lead times.

Can I hand solder PCB assemblies?

For prototypes and very low quantities (<10 boards), hand soldering is feasible. But for production volumes, automated SMT assembly is faster, lower cost, and more consistent quality.

How much does low volume PCB assembly cost?

Typical costs are $200-300 for assembling 10 simple boards, and $2,000-4,000 for assembling 100 boards. Costs increase with board complexity and decrease significantly with larger orders.

Should I order assembled PCBs from the same manufacturer as bare boards?

Often yes, using the same provider avoids compatibility issues and reduces logistics effort. But you can use different assemblers to get the best bare board and assembly prices.

How can I get accurate PCB assembly quotations?

Upload your PCB and BOM files to online instant quote tools from assembly services. Make sure to select all required assembly options. Contact sales reps if you need customized services.

0 Comments