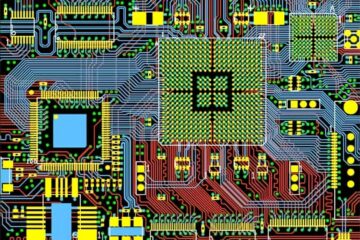

PCBA

How to Make a PCB Prototype?

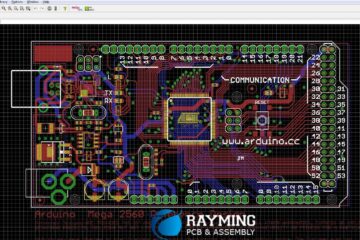

In the world of electronics, the process of transforming an idea into a functional device often begins with the creation of a PCB (Printed Circuit Board) prototype. A PCB prototype is a preliminary version of the final PCB design, used for testing, evaluation, and refinement before moving into full-scale production. Read more…