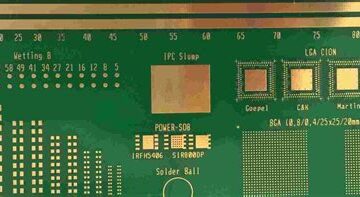

PCBA

Selection Chip Capacitor & Its Storage

Introduction to Chip Capacitors Chip capacitors, also known as multilayer ceramic capacitors (MLCCs), are essential components in modern electronic devices. These tiny, surface-mounted devices are used for a variety of purposes, including filtering, decoupling, and energy storage. With the increasing demand for smaller, more efficient electronic devices, the importance of chip capacitors has grown significantly in recent years. Types of Chip Capacitors There are several types of chip capacitors available, each with its own unique Read more…