What are Vias in PCB Design?

Vias are an essential component in printed circuit board (PCB) design. A via is a small hole drilled through a PCB that allows electrical connection between different layers of the board. Vias enable traces and components on different layers to connect, allowing designers to route signals and power across the PCB in a compact and efficient manner.

There are several types of vias used in PCB design:

| Via Type | Description |

|---|---|

| Through Hole Via | Drilled through the entire board, connecting all layers |

| Blind Via | Connects an outer layer to an inner layer, but does not go through the entire board |

| Buried Via | Connects two or more inner layers, but does not extend to the outer layers |

| Microvia | A small via, typically less than 6 mils in diameter, used for high-density interconnect (HDI) boards |

The choice of via type depends on the specific design requirements, such as board thickness, layer count, signal integrity, and manufacturing capabilities.

Why is Via Analysis Important?

Analyzing vias is crucial for ensuring the reliability, manufacturability, and performance of a PCB. Some key reasons for conducting via analysis include:

Signal Integrity

Vias can introduce discontinuities in the signal path, leading to reflections, crosstalk, and other signal integrity issues. By analyzing via geometry, placement, and spacing, designers can minimize these effects and maintain signal quality.

Manufacturability

Via size, aspect ratio, and placement can impact the manufacturability of a PCB. Analyzing these factors helps ensure that the board can be reliably manufactured with minimal defects and yield loss.

Thermal Management

Vias play a role in heat dissipation by providing a thermal path between layers and to the board’s surface. Analyzing via size, placement, and fill material can optimize thermal management and prevent overheating of components.

Reliability

Vias are subject to mechanical and thermal stresses during assembly and operation. Analyzing via size, aspect ratio, and fill material can help prevent via failures, such as barrel cracks or delamination.

Via Analysis Techniques

Several techniques are used to analyze vias in PCB design, including:

Design Rule Checking (DRC)

DRC is an automated process that checks the PCB layout against a set of predefined rules, including via size, spacing, and aspect ratio. DRC helps identify potential manufacturability and reliability issues early in the design process.

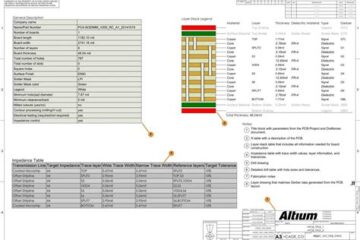

Signal Integrity Simulation

Signal integrity simulation tools can model the effects of vias on signal propagation, including impedance discontinuities, reflections, and crosstalk. These simulations help designers optimize via placement and geometry for improved signal quality.

Thermal Simulation

Thermal simulation tools can model the heat transfer through vias and predict the temperature distribution across the PCB. This analysis helps designers optimize via placement and fill material for effective thermal management.

Cross-sectional Analysis

Cross-sectional analysis involves physically cutting and examining a PCB to assess via quality and integrity. This destructive technique is typically used for failure analysis or process validation.

Best Practices for Via Design

To minimize the potential issues associated with vias and ensure optimal PCB performance, designers should follow these best practices:

Minimize Via Count

Reducing the number of vias in a design can improve manufacturability, reliability, and signal integrity. Designers should optimize the PCB layout to minimize the need for vias whenever possible.

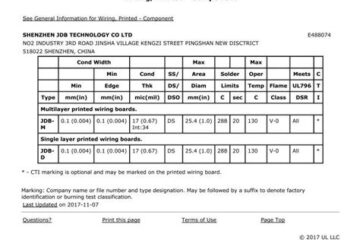

Use Appropriate Via Size and Aspect Ratio

Via size and aspect ratio should be chosen based on the specific design requirements and manufacturing capabilities. Generally, smaller vias are preferred for high-density designs, while larger vias may be necessary for improved thermal management or manufacturability.

Optimize Via Placement

Via placement should be optimized to minimize signal integrity issues, such as reflections and crosstalk. Vias should be placed away from sensitive signals and spaced appropriately to prevent coupling.

Use Via Shielding and Stitching

Via shielding involves placing ground vias adjacent to signal vias to provide a return path and reduce crosstalk. Via stitching involves placing closely spaced vias to create a low-impedance connection between ground planes, which can improve signal integrity and EMI performance.

Consider Via Fill Material

The choice of via fill material can impact the thermal and mechanical properties of the via. Copper-filled vias provide the best thermal conductivity but may be more expensive and difficult to manufacture. Epoxy-filled vias are cheaper and easier to process but have lower thermal conductivity.

Frequently Asked Questions (FAQ)

1. What is the difference between a through hole via and a blind via?

A through hole via extends through the entire thickness of the PCB, connecting all layers. A blind via, on the other hand, connects an outer layer to one or more inner layers, but does not go through the entire board thickness.

2. How do vias affect signal integrity in high-speed PCB designs?

Vias can introduce impedance discontinuities, reflections, and crosstalk in high-speed signals. These effects can degrade signal quality and lead to errors or failures. To minimize these issues, designers must carefully analyze and optimize via geometry, placement, and spacing.

3. What is via aspect ratio, and why is it important?

Via aspect ratio is the ratio of via depth to diameter. High aspect ratio vias (greater than 8:1) can be difficult to manufacture reliably, as they may not be completely plated or filled. Low aspect ratio vias are easier to produce but may take up more board space. Designers must balance these factors based on the specific design requirements and manufacturing capabilities.

4. How can thermal simulation help in via analysis?

Thermal simulation tools can model the heat transfer through vias and predict the temperature distribution across the PCB. This analysis helps designers optimize via placement and fill material to ensure effective thermal management and prevent overheating of components.

5. What is via stitching, and when is it used?

Via stitching involves placing closely spaced vias to create a low-impedance connection between ground planes. This technique is used to improve signal integrity and EMI performance in high-speed designs. Via stitching can help reduce ground bounce, provide a stable reference plane, and minimize radiated emissions.

Conclusion

Via analysis is a critical aspect of PCB design, ensuring the reliability, manufacturability, and performance of the final product. By understanding the different types of vias, their impact on signal integrity, thermal management, and reliability, designers can make informed decisions and optimize their designs accordingly.

Through the use of DRC, signal integrity simulation, thermal simulation, and cross-sectional analysis, designers can identify and mitigate potential issues associated with vias. Following best practices, such as minimizing via count, using appropriate via size and aspect ratio, optimizing placement, and considering fill material, can further enhance the quality and reliability of the PCB.

As PCB designs continue to push the boundaries of complexity and performance, the importance of via analysis will only continue to grow. By staying informed about the latest techniques and best practices, PCB designers can ensure that their products meet the ever-increasing demands of modern electronics.

0 Comments