PCBA

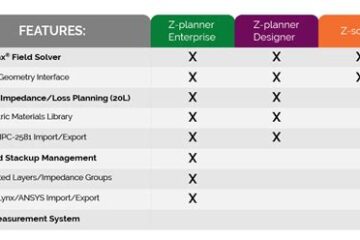

Guides for 10-Layer PCB Stack-up

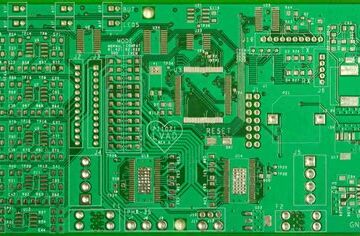

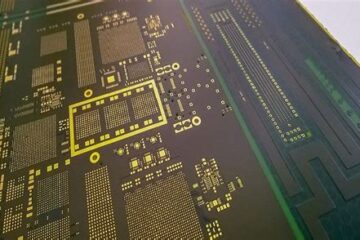

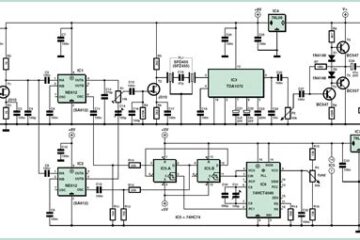

Introduction to PCB Stack-up A printed circuit board (PCB) stack-up refers to the arrangement of copper layers and insulating materials that make up a PCB. The stack-up determines the electrical properties, signal integrity, and manufacturability of the board. As technology advances and designs become more complex, multi-layer PCBs have become increasingly common. In this article, we will focus on 10-layer PCB stack-ups, providing comprehensive guides on how to design and optimize them for various applications. Read more…