Introduction

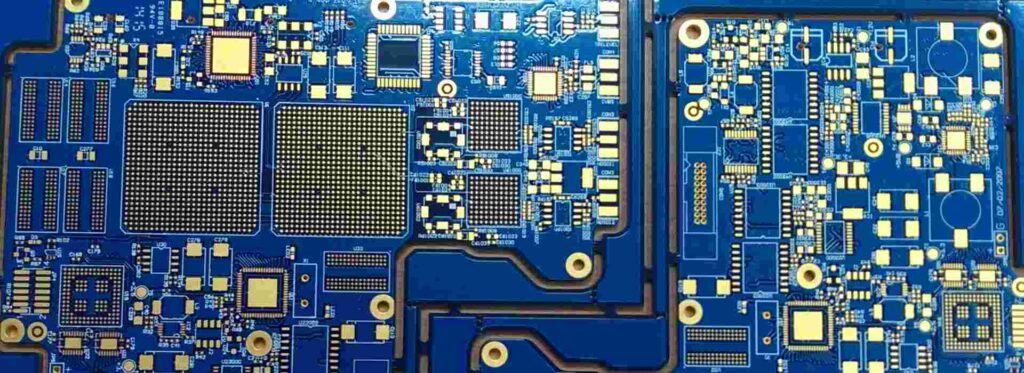

Printed circuit boards (PCBs) have become an essential component of most modern electronics. From computers and smartphones to appliances and vehicles, PCBs provide the necessary physical platform to mount and connect the various electronic components of a device. As a result, the global PCB market continues to grow in tandem with the electronics industry. According to research, the PCB market is projected to reach $77.7 billion by 2026.

With this growing demand for PCBs, choosing the right manufacturing partner is crucial for producing high-quality boards tailored to your product’s needs. This guide examines key factors to consider when selecting a PCB manufacturer, profiles leading global PCB companies, and provides tips for getting started.

Key Factors When Selecting a PCB Manufacturer

Types of PCBs Offered

There are several types of PCBs, including:

- Single-sided – Circuitry on one side only

- Double-sided – Circuitry on both sides

- Multilayer – Multiple conductive layers laminated together

- Rigid – Standard inflexible boards

- Flexible – Can bend and flex

- Rigid-flex – Combination of both

Look for manufacturers that specialize in producing the types of PCBs you need for your product. Multilayer boards are more complex and require specialized equipment and technical expertise.

Volume Production Capabilities

The scale of production capabilities should align with your project needs. Some suppliers only produce prototypes and low volumes, while others cater to high-volume production runs.

Quality Certifications

Reputable PCB manufacturers should have quality management certifications such as ISO 9001 or IATF 16949. These standards demonstrate adherence to robust quality systems.

Design File Formats

Most manufacturers accept Gerber files, but some have additional proprietary software and accept other file formats too. Choose a supplier that is compatible with your design files.

Lead Times

Verify that the supplier can deliver your prototype or production order within your project timeline. Lead times can range from 24 hours for rush prototypes to several weeks for mass production runs.

Location and Logistics

Choosing a supplier located close to your team or market can help reduce shipping costs and delays. Some global manufacturers have local sales offices or production facilities worldwide.

Leading PCB Manufacturing Companies

Here are some of the top PCB manufacturers operating worldwide:

Advanced Circuits

- One of the largest PCB manufacturers in the US

- Capabilities: prototype to mid-volume production, multilayer, rigid, flex, rigid-flex

- Quality certifications: ISO 9001:2015

- Locations: Colorado, Minnesota

TTM Technologies

- Global PCB manufacturer with sites worldwide

- Capabilities: prototype to high-volume, multilayer, rigid, flex, rigid-flex, HDI

- Quality certifications: ISO 9001, AS9100, IATF 16949

- Locations: North America, Asia, Europe

AT&S

- Leading European PCB producer

- Capabilities: high-tech PCBs, IC substrates, HDI, rigid-flex

- Quality certifications: IATF 16949, ISO 9001, ISO 14001

- Locations: Austria, India, China, South Korea

Compeq

- Major PCB manufacturer in Taiwan

- Capabilities: multilayer boards, high-density interconnects

- Quality certifications: ISO 9001, ISO 14001

- Locations: Taiwan, China, Vietnam

Sanmina Corporation

- Top EMS company with PCB manufacturing

- Capabilities: prototype to high-volume production

- Quality certifications: ISO 13485, ISO 14001, IATF 16949

- Locations: North America, Europe, Asia

Choosing the Right PCB Partner for Your Needs

Prototyping Stage

For early prototyping, choose a manufacturer that offers quick-turnaround on low volumes, such asAdvanced Circuits or TTM Technologies. Speed and flexibility are crucial at this stage.

New Product Introduction

As you prepare to launch and ramp up production, opt for a supplier with the expertise to manufacture your particular type of PCB at small-to-medium volumes.

High-Volume Production

For established products with steady demand, leverage a high-volume manufacturer like TTM or Sanmina to achieve maximum efficiency and cost savings.

High-Complexity PCBs

For advanced PCB technologies like HDI, flexible or rigid-flex boards, choose a specialist like AT&S.

Full Product Assembly

If you need PCB assembly and testing along with manufacturing, consider a full-service EMS provider like Sanmina.

Getting Started with Your PCB Manufacturer

Research Companies

Use this guide to draw up a shortlist of potential PCB manufacturers suited to your needs. Browse their websites for capabilities details.

Get Quotes

Contact suppliers to get quotes for your required order volumes and production timelines. Provide your PCB design files for accurate pricing.

Evaluate Options

Compare the pricing, lead times, and production locations between prospective manufacturers. Weigh the pros and cons to select your ideal partner.

Ask Questions

Discuss any questions you have about the PCB specifications, manufacturing processes, quality assurance, and other factors to ensure a shared understanding.

Tour Facilities (If Possible)

For higher-volume production, arrange site visits to tour prospective manufacturers’ facilities firsthand. This provides deeper visibility into their operations.

Place Order

Once you’ve selected your preferred PCB manufacturing partner, get started by placing your first order. Be sure to follow their design rules and file format requirements.

Conclusion

Choosing the right PCB manufacturing partner is a key step in turning your electronics design into reality. Carefully evaluate prospective suppliers based on their capabilities, certifications, production scale, and compatibility with your specific needs. Partnering with the most well-suited PCB company will ensure you receive high-quality boards delivered on time and enable successful deployment of your product.

Frequently Asked Questions

Q: What are the most important factors when selecting a PCB manufacturer?

A: The key factors are: types of PCBs produced, volume production capabilities, quality certifications, design file formats accepted, lead times, and location. Match these to your specific project requirements and PCB needs.

Q: How do the lead times for PCB manufacturing compare?

A: For prototypes, lead times can be as fast as 24 hours for basic boards from quick-turn suppliers. For higher complexity boards produced in small batches, lead times range from about 5 days to 3 weeks. Mass production of larger orders generally takes 3-8 weeks for delivery.

Q: Should I use a PCB manufacturer located closer to my team?

A: There are some potential advantages to using a geographically close supplier, such as faster delivery, lower shipping costs, and easier communication. However, the most important factors are their capabilities, quality, pricing, and delivery timelines. Don’t limit your choices geographically if another manufacturer is a better fit.

Q: What are flexible PCBs used for?

A: Flexible PCBs can bend, twist, and flex. This makes them well-suited for products where flexibility is required, like wearable devices, medical equipment, consumer electronics, and automotive electronics. The circuits in flexible PCBs use conductive ink instead of copper tracks.

Q: How can I get lower costs for higher-volume PCB orders?

A: For production volumes over 10,000+ units, negotiating with manufacturers can result in significantly lower per unit pricing. You can also reduce costs by keeping circuit designs simpler, allowing longer lead times, and standardizing on a single PCB supplier.

0 Comments