In today’s rapidly evolving electronics industry, the demand for high-quality printed circuit boards (PCBs) has skyrocketed. Whether you’re a hobbyist, an independent designer, or a business owner, finding reliable and conveniently located PCB manufacturers is crucial for bringing your electronic projects to life. With a vast array of manufacturers offering various services and capabilities, the task of identifying the right partner can be daunting. This comprehensive guide will walk you through the process of finding PCB manufacturers near you, exploring various strategies and resources to ensure a seamless and successful collaboration.

Understanding PCB Manufacturing

Before delving into the process of finding local PCB manufacturers, it’s essential to understand the basics of PCB manufacturing and the different services offered.

What is a PCB?

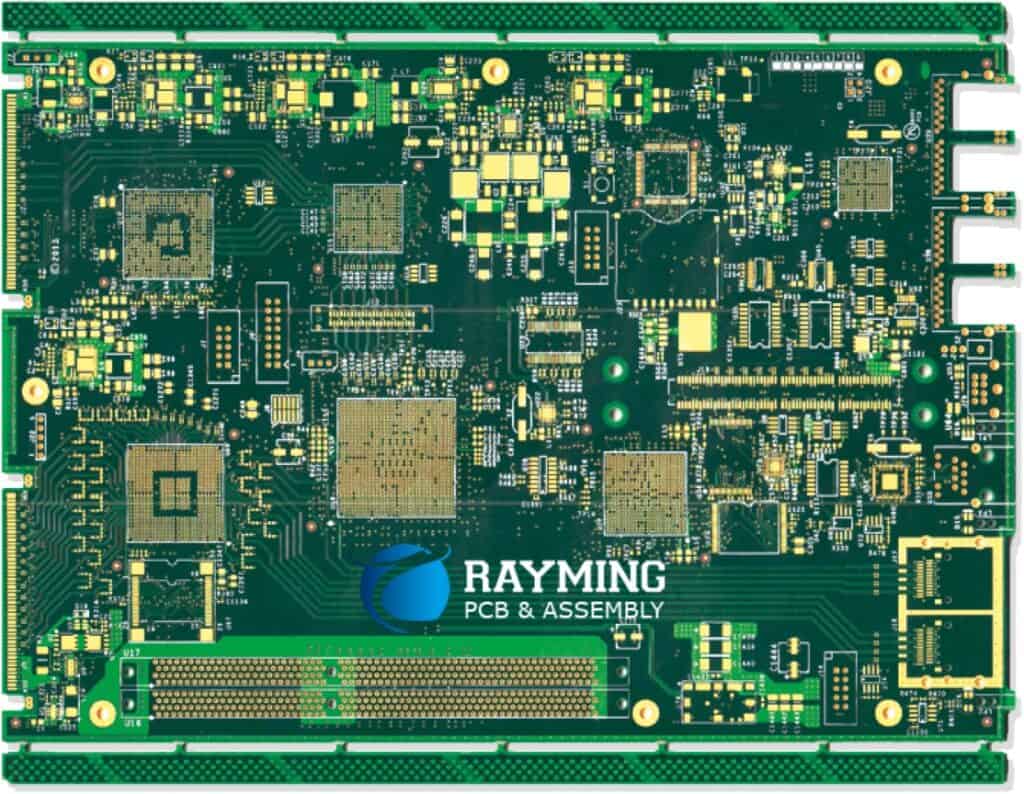

A printed circuit board (PCB) is a non-conductive substrate made of materials like fiberglass or phenolic resin, onto which conductive copper tracks and pads are etched or printed. These tracks and pads serve as the interconnections for various electronic components, such as integrated circuits (ICs), resistors, capacitors, and other discrete components, forming the backbone of virtually all electronic devices.

Types of PCB Manufacturing Services

PCB manufacturers offer a range of services to cater to different project requirements and production volumes. Here are some common services:

- Prototype PCB Manufacturing: Ideal for low-volume production, prototype PCB manufacturing allows for rapid turnaround times and is often used for testing and evaluation purposes.

- Small-Batch PCB Manufacturing: Small-batch PCB manufacturing is suitable for low to medium-volume production runs, catering to the needs of hobbyists, independent designers, and small businesses.

- High-Volume PCB Manufacturing: Large-scale PCB manufacturers offer high-volume production capabilities, typically for mass-market consumer electronics or industrial applications.

- PCB Assembly: In addition to manufacturing PCBs, some manufacturers also offer PCB assembly services, where they mount and solder electronic components onto the PCBs, providing a complete turnkey solution.

- PCB Prototyping: Rapid prototyping services allow for quick turnaround times, enabling designers and engineers to iterate and refine their designs before moving to full-scale production.

Strategies for Finding PCB Manufacturers Near You

Locating PCB manufacturers in your vicinity can be accomplished through various strategies, each offering its own advantages and considerations.

Online Directories and Search Engines

One of the most accessible methods for finding local PCB manufacturers is by utilizing online directories and search engines. These platforms allow you to search for manufacturers based on your location and specific requirements.

Popular online directories and search engines for PCB manufacturers include:

- Google Search (e.g., “PCB manufacturers near me”)

- PCB Manufacturing Directories (e.g., PCB Directory, PCB Manufacturers List)

- Business Listing Websites (e.g., Yelp, Yellow Pages)

- Industry-Specific Directories (e.g., IPC PCB Manufacturer Directory)

When using these resources, be sure to refine your search by including relevant keywords such as “local,” “nearby,” or your specific city or region. Additionally, review the manufacturer’s website and offerings to ensure they align with your project requirements.

Local Electronics Communities and Meetups

Engaging with local electronics communities and attending meetups can be an excellent way to connect with fellow enthusiasts, designers, and engineers who may have firsthand experience working with nearby PCB manufacturers. These communities often serve as valuable resources for recommendations, feedback, and insights into the capabilities and reliability of local service providers.

Local electronics communities can be found through platforms such as:

- Meetup.com

- Facebook Groups

- Local Maker Spaces or Hackerspaces

- Online Forums (e.g., EEVBlog, Instructables)

By actively participating in these communities, you can tap into a wealth of knowledge and potentially discover reliable PCB manufacturers in your area.

Trade Shows and Industry Events

Attending trade shows and industry events focused on electronics, PCB manufacturing, or related fields can provide a unique opportunity to network with manufacturers and explore their offerings in person. These events often feature exhibitor booths where manufacturers showcase their capabilities and services, allowing you to engage directly with representatives and gather valuable information.

Some notable trade shows and events to consider:

- DesignCon

- IPC APEX EXPO

- electronica

- NEPCON

- Local or regional electronics expos and conventions

Attending these events not only allows you to explore potential manufacturers but also provides insights into the latest trends, technologies, and best practices in the PCB manufacturing industry.

Local Business Directories and Chambers of Commerce

Local business directories and chambers of commerce can be valuable resources for identifying PCB manufacturers operating in your area. These organizations often maintain comprehensive listings of businesses within a specific region, including manufacturers and service providers.

By contacting your local chamber of commerce or consulting business directories, you can obtain a list of potential PCB manufacturers in your vicinity. This approach can be particularly useful if you prefer to work with manufacturers that have a physical presence and established reputation in your local community.

Word-of-Mouth and Referrals

In many industries, word-of-mouth and referrals can be powerful tools for finding reliable service providers. Reach out to your professional network, including fellow engineers, designers, hobbyists, or business owners in the electronics industry, and inquire about their experiences with local PCB manufacturers.

Positive recommendations from trusted sources can provide valuable insights into the quality, reliability, and customer service of potential manufacturers, helping you make an informed decision.

Evaluating and Selecting PCB Manufacturers

Once you’ve identified potential PCB manufacturers in your area, it’s crucial to evaluate them based on various factors to ensure a successful collaboration.

Key Evaluation Criteria

When evaluating PCB manufacturers, consider the following criteria:

- Capabilities and Services Offered: Ensure that the manufacturer’s capabilities and services align with your project requirements, such as PCB complexity, production volume, assembly services, and prototyping options.

- Quality Standards and Certifications: Reputable manufacturers should adhere to industry standards and hold relevant certifications, such as ISO 9001, IPC-A-600, or UL certifications, ensuring consistent quality and compliance.

- Turnaround Times: Evaluate the manufacturer’s turnaround times for prototype, small-batch, and high-volume production to ensure they meet your project timelines.

- Customer Service and Communication: Effective communication and responsive customer service are essential for a smooth collaboration. Assess the manufacturer’s responsiveness and willingness to address your questions and concerns.

- Pricing and Cost-Effectiveness: Compare pricing and cost-effectiveness across different manufacturers, considering factors such as production volume, materials, and additional services required.

- Reviews and Reputation: Research online reviews, testimonials, and the manufacturer’s reputation within the industry and local community to gauge their reliability and customer satisfaction.

- Proximity and Logistics: Consider the manufacturer’s proximity to your location, as well as their logistics capabilities for efficient delivery and support.

Site Visits and In-Person Evaluation

To gain a comprehensive understanding of a potential PCB manufacturer, consider scheduling a site visit or requesting an in-person evaluation. This hands-on approach allows you to observe their facilities, production processes, quality control measures, and interact directly with their staff.

During a site visit, pay attention to the following aspects:

- Cleanliness and organization of the production area

- Quality control procedures and testing facilities

- Expertise and experience of the staff

- Production equipment and technology utilized

- Environmental and safety practices

A site visit can provide valuable insights into the manufacturer’s commitment to quality, professionalism, and adherence to industry best practices.

Working with PCB Manufacturers

Once you’ve selected a suitable PCB manufacturer, it’s essential to establish a productive and collaborative working relationship to ensure a successful project outcome.

Effective Communication

Clear and consistent communication is crucial when working with a PCB manufacturer. Establish a designated point of contact and preferred communication channels (e.g., email, phone, video conferencing) to streamline the exchange of information and address any concerns or questions that may arise.

Provide detailed specifications, design files, and requirements upfront to minimize misunderstandings and ensure accurate production. Additionally, maintain open lines of communication throughout the production process, requesting updates and addressing any issues promptly.

Design for Manufacturability (DFM)

Design for Manufacturability (DFM) is a critical aspect of PCB design that involves optimizing the design to ensure efficient and cost-effective manufacturing. Work closely with your chosen PCB manufacturer to understand their capabilities, design guidelines, and recommended practices.

By incorporating DFM principles early in the design process, you can minimize potential issues, reduce production costs, and streamline the manufacturing process.

Quality Control and Testing

Discuss quality control procedures and testing requirements with your PCB manufacturer. Reputable manufacturers should have robust quality control processes in place, including electrical testing, visual inspection, and adherence to industry standards.

If necessary, request samples or prototypes for evaluation and testing prior to full-scale production. This allows you to verify the quality and functionality of the PCBs and make any necessary adjustments or modifications before committing to a larger production run.

Intellectual Property Protection

When working with PCB manufacturers, intellectual property protection is a crucial consideration. Discuss and establish clear agreements regarding the confidentiality and protection of your designs, schematics, and other proprietary information.

Reputable manufacturers should have robust policies and procedures in place to safeguard your intellectual property, ensuring that your designs and sensitive information are handled with the utmost care and confidentiality.

Collaboration and Partnership

Fostering a collaborative and partnership-oriented relationship with your PCB manufacturer can lead to long-term success and mutual benefit. Be open to feedback and suggestions from the manufacturer, as they often possess valuable expertise and insights into optimizing designs, improving manufacturing processes, and reducing costs.

By establishing a strong partnership based on trust, open communication, and a shared commitment to quality, you can leverage the manufacturer’s capabilities to their fullest potential and achieve successful outcomes for your projects.

Table: Comparison of PCB Manufacturing Services

| Service | Description | Typical Use Cases | Advantages | Considerations |

|---|---|---|---|---|

| Prototype PCB Manufacturing | Low-volume production for testing and evaluation purposes | Prototyping, initial product development, design verification | Rapid turnaround times, cost-effective for small runs | Limited production quantities, may have higher per-unit costs |

| Small-Batch PCB Manufacturing | Low to medium-volume production runs | Hobbyists, independent designers, small businesses | Flexibility, customization options, shorter lead times | Higher per-unit costs compared to high-volume production |

| High-Volume PCB Manufacturing | Large-scale production for mass-market applications | Consumer electronics, industrial applications | Economies of scale, lower per-unit costs | Higher setup costs, longer lead times, minimum order quantities |

| PCB Assembly | Mounting and soldering of electronic components onto PCBs | Complete turnkey solution for various industries | Time-saving, streamlined production process | Additional costs for assembly services, potential for higher defect rates |

| PCB Prototyping | Rapid prototyping services for iterative design and testing | Concept validation, design refinement, proof-of-concept | Accelerated development cycles, early identification of issues | Limited production quantities, higher per-unit costs |

FAQ (Frequently Asked Questions)

- Q: Why is it important to find local PCB manufacturers? A: Finding local PCB manufacturers can offer several advantages, including shorter lead times, easier communication and collaboration, potential cost savings, and the ability to establish a more personal and responsive working relationship.

- Q: What should I consider when evaluating PCB manufacturers? A: When evaluating PCB manufacturers, consider factors such as their capabilities and services offered, quality standards and certifications, turnaround times, customer service and communication, pricing and cost-effectiveness, reviews and reputation, and proximity and logistics.

- Q: How can I ensure effective communication with my chosen PCB manufacturer? A: Effective communication is essential for a successful collaboration. Establish a designated point of contact, preferred communication channels, provide detailed specifications and requirements upfront, and maintain open lines of communication throughout the production process.

- Q: What is Design for Manufacturability (DFM), and why is it important? A: Design for Manufacturability (DFM) involves optimizing the PCB design to ensure efficient and cost-effective manufacturing. Incorporating DFM principles early in the design process can minimize potential issues, reduce production costs, and streamline the manufacturing process.

- Q: How can I protect my intellectual property when working with PCB manufacturers? A: To protect your intellectual property, discuss and establish clear agreements regarding the confidentiality and protection of your designs, schematics, and proprietary information. Reputable manufacturers should have robust policies and procedures in place to safeguard your intellectual property.

Conclusion

Finding reliable and conveniently located PCB manufacturers is crucial for the success of your electronic projects. By leveraging the strategies outlined in this guide, including online directories, local communities, trade shows, business directories, and word-of-mouth referrals, you can identify potential manufacturers in your area.

Thorough evaluation based on factors such as capabilities, quality standards, turnaround times, customer service, pricing, and reputation is essential to ensure a successful collaboration. Fostering effective communication, adhering to Design for Manufacturability principles, and establishing a collaborative partnership with your chosen PCB manufacturer can lead to positive outcomes and long-term success.

Remember, the process of finding the right PCB manufacturer near you requires due diligence, research, and a commitment to quality and excellence. By following the best practices outlined in this guide, you can navigate the process with confidence and bring your electronic designs to life with the support of a reliable and capable local PCB manufacturing partner.

0 Comments