Printed circuit board (PCB) assembly is an essential part of electronics manufacturing. Choosing the right PCB assembly supplier can impact product quality, cost, and delivery timelines. This article profiles the top 5 PCB assembly suppliers in Colorado based on factors like capabilities, experience, certifications, and customer reviews.

Overview of PCB Assembly Process

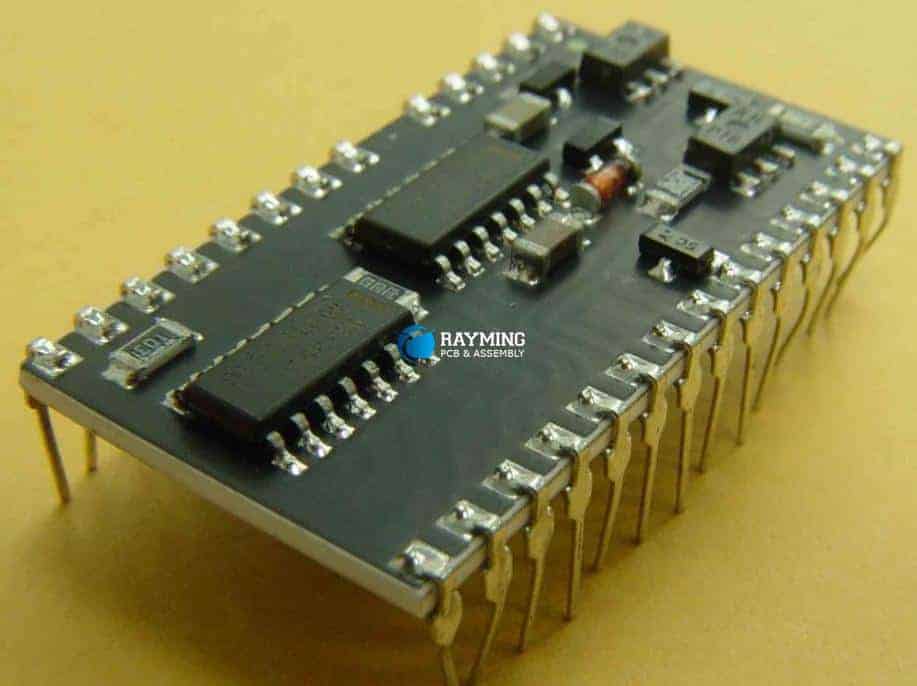

Before diving into the top suppliers, let’s quickly understand what PCB assembly involves. The PCB assembly process consists of:

Sourcing PCB Components

The PCB assembly company sources required components like integrated circuits (ICs), resistors, capacitors etc. from various manufacturers to populate the printed circuit board.

Solder Paste Printing

The PCB board goes through a solder printer that prints an exact pattern of solder paste on all the points where components need to be soldered.

Pick and Place Assembly

Pick and place machines automatically pick components from reels and place them precisely on the PCB board.

Reflow Soldering

The board goes through a reflow oven that melts the solder paste to attach components permanently to the board.

Testing and Inspection

Once assembled, the board is tested thoroughly to ensure proper functioning. Visual inspection under microscope checks for quality of solder joints, component placement accuracy etc.

Conformal Coating

For boards going into harsh environments, the assembled PCBs are coated with protective acrylic or silicone layers.

Now let’s look at the top 5 PCB assembly suppliers in Colorado.

1. Advanced Circuits

Advanced Circuits is ranked among the top PCB manufacturers in the USA with over 25 years of experience in the industry. They have a 70,000 sq. ft. facility in Aurora, CO with SMT assembly lines from Fuji and Panasonic.

Capabilities

- Surface mount and thru-hole component assembly

- 0201 imperial and 0.4 mm metric component capability

- Fine pitch BGAs with 0.4 mm pitch

- Lead-free assembly

- 90+ lead times for assembled boards in small volumes

- AS9100 and ISO 9001 certified

Available Services

- Design for manufacturing (DFM) reviews

- PCB layout recommendations

- Test development

- Prototyping

- Quick turn low volume production

- Medium to high volume production

With robust quality controls and inspection processes in place, Advanced Circuits delivers high-reliability electronics assembly solutions catering to defense, aerospace, industrial, medical, telecommunications and other high-tech sectors.

2. Screaming Circuits

Screaming Circuits was founded in 2003 and specializes in low-mid volume PCB assembly catering to engineers, startups, universities and makers. Their Oregon assembly facility has the latest equipment – Juki pick and place and Vitronics Soltec reflow.

Capabilities

- 01005 imperial components (0.4mm x 0.2mm metric)

- BGA package sizes down to 12 mil pitch

- Lead free assembly

- 90% on-time delivery

- ISO 9001:2008, ITAR registration

Available services

- Full turnkey PCB assembly

- Design reviews

- Test fixture development

- Functional testing

- Flying probe

- Box build

- Supply chain management

Screaming Circuits provides online DFM analysis, quotes and ordering system allowing customers get boards assembled rapidly without huge setup charges. Their unique “Scheduled Volume Pricing” offers increasing discounts on additional boards allowing flexibility in production volumes.

3. U.S. Circuits

U.S. Circuits has over 50 years of PCB manufacturing expertise backed by UL recognition, ISO 13485 and 9001 certifications. They have partnered with Season Group for providing electronics turnkey assembly solutions out of their Colorado facility.

Capabilities

- 01005 components (Size: 0.4mm x 0.2mm)

- Lead-free RoHS and REACH compliant assembly

- BGA package capability

- Flex and rigid-flex PCB solutions

- 5-7 day standard assembly time

Available Services

- SMT Pick and Place Assembly

- Automated optical inspection

- PCB functional testing

- Selective soldering

- Box build services

- Supply chain solution

- New product introduction (NPI)

- Low to medium volume production

U.S. Circuits provides valuable design for manufacturing feedback to customers early in the PCB development cycle to avoid common pitfalls that impact quality, cost and manufacturability down the line.

4. Titian Circuits

Titian Circuits is a full service PCB solutions company providing PCB design, fabrication and assembly services globally. For SMT assembly they partner with Season Group USA.

Capabilities

- High mix, low volume flexibility

- 01005 component size (0.4mm x 0.2mm metric)

- Fine pitch BGAs and QFN packages

- 90+ lead time on assembled boards

- UL listed and ITAR registered

Available Services

- Full turnkey PCB assembly

- NPI, prototyping, short runs

- Design for manufacturing reviews

- Complete PCB solutions

- PCB design

- Fabrication

- Assembly

- Box build services

With teams in China and United States, Titan Circuits provides seamless manufacturing hand-off of complex PCB designs minimizing lead times and costs no matter what stage of the product life cycle.

5. Summer Circuits

Summer Circuits provides advanced PCB solutions spanning design, fabrication and assembly catering to startups, entrepreneurs and engineers. Their California based assembly lines can populate even the most complex board designs reliably in low to medium volumes.

Capabilities

- 01005 component size expertise

- Advanced BGAs, 0.4mm pitch QFNs

- 90% on time delivery

- 5 day assembly time

- IPC Class 2 and 3 certifications

Available services

- Complete PCB assembly

- Functional testing

- Flying probe electrical test

- Design and DFM reviews

- Supply chain partnerships

- Small scale manufacturing

- Quick turn prototypes

Summer Circuits offers valuable design recommendations to optimize manufacturability and overall project success from start to finish. Their online quoting and ordering platform makes procurement easy.

Comparison of Top PCB Assembly Suppliers in Colorado

| Supplier | Location | Capabilities | Volume Expertise | Certifications |

|---|---|---|---|---|

| Advanced Circuits | Aurora, CO | Advanced packaging <br> 0201 components <br> Lead-free capability | Quickturn protoypes <br> Low to high volume production | AS9100 <br> ISO 9001 |

| Screaming Circuits | Oregon (with Colorado facility) | Tiny 01005 components <br> Fine pitch BGAs <br> 90% on time delivery | Low to medium volumes <br>Scheduled volume pricing | ISO 9001:2008 <br> ITAR |

| U.S. Circuits | Colorado (with Season Group) | 01005 component expertise <br> Flex PCB capability <br> 5-7 day assembly time | Low to medium volume | ISO 13485 <br> ISO 9001 <br> UL listing |

| Titan Circuits | California (with Season Group Colorado) | 01005 component expertise <br> 90+ lead time | High mix, low volume | UL listed <br> ITAR registered |

| Summer Circuits | California (with Colorado facility) | 01005 components <br> 5 day assembly time <br> 90% on time delivery | Low to medium volume | IPC 2 & 3 certification |

Buyer’s Guide – Choosing Right PCB Assembly Partner

Here are some key considerations when selecting an electronics contract manufacturer for your project:

Capabilities – Ensure the assembler supports your board’s component sizes, densities and package types like BGAs and QFNs. Tiny metric component capability is key.

Quality – Look for assemblers with IPC certifications confirming their soldering, inspection and training quality management. ISO 9001 and 13485 are added stamps of quality approval.

Volume Expertise – Prototype and short run requirements may need more hands on support versus process driven mid-high volume production.

Lead Time – Watch out for production backlogs resulting in much longer delays than advertised lead times during capacity crunches.

Location – Closer geographic proximity allows tighter supplier oversight especially for lower volume ramp up projects.

Pricing – Compare board area pricing across a few different complexity classes to identify any outlier premiums outliers charging much higher for more complex boards.

DFM Expertise – The earlier you engage the assembly partner, the more design tweaks they can suggest to enhance manufacturability, testability, cost savings and overall project success.

One Stop Solution – Using a fully integrated supplier providing PCB layout, fabrication and assembly ensures better accountability with no finger pointing between multiple vendors.

Frequently Asked Questions

Here are some common questions about PCB assembly services:

Q: Does assembly service include component sourcing?

In most cases, turnkey PCB assembly includes procuring all required components specified in the bill of materials (BOM). It takes the procurement workload off the engineering teams with specialized buyers negotiating with various authorized parts distributors.

Q: Can I provide some special components myself?

Yes, you can supply components not readily available or involving long lead times to the assembly partner. This hybrid model allows flexibility in sourcing.

Q: What data do I provide to the assembler?

You’ll need to provide complete PCB data package – Gerber files, drill drawing, netlist, bill of materials with component references designators matching PCB layout, any specific assembly instructions.

Q: Can I get functional testing done during assembly?

Most assembly providers offer post-assembly testing like burn-in of boards, flying probe as well as design of test fixtures for complex boards to validate assembly. Discuss your testing needs upfront.

Q: How are boards protected during shipment?

Assembled boards are packed securely using ESD safe bags and then boxed with foam/spacer constraints to prevent shipping damage.

This covers the top electronics PCB assembly partners in Colorado capable of supporting low volume to mid-high volume production. Engage early with potential partners to get their design and sourcing input for improving manufacturability and quality.

0 Comments