Led Pcb Manufacturer: A Complete Guide

Led pcb manufacturer is a phrase that refers to companies that specialize in manufacturing printed circuit boards (PCBs) designed specifically for light emitting diode (LED) applications. As LED technology has advanced and become more widespread in use, the demand for high-quality LED PCBs has grown substantially. This article provides a comprehensive overview of LED PCB manufacturing, including the key players, manufacturing processes, design considerations, and trends shaping the industry.

What is a Led Pcb Manufacturer?

A led pcb manufacturer is a company that fabricates printed circuit boards optimized for mounting and connecting LED components. LED PCBs require specialized design and manufacturing capabilities to accommodate the unique demands of LED systems.

Key responsibilities of a led pcb manufacturer include:

- Designing PCBs tailored to LED applications

- Selecting suitable board materials, like aluminum or ceramic, for optimal thermal performance

- Implementing adequate thermal management strategies, like thru-hole vias and pads, to dissipate heat

- Fabricating complex, multilayer PCBs to manage high LED power

- Assembling boards with precision placement of small LED components

- Testing finished boards for quality assurance and reliability

The role of a led pcb manufacturer is critical in enabling the safe, efficient and cost-effective use of LED technology in products like LED lighting fixtures, displays, automotive lighting and more.

Major Led Pcb Manufacturers

The LED PCB manufacturing industry is growing rapidly to meet rising market demand. Some of the major global manufacturers of LED PCBs include:

Kinglight

Founded in 1993 in Shenzhen, China, Kinglight has grown into one of the world’s leading LED PCB manufacturing companies. They produce PCBs for lighting, display, automotive and other LED applications. Kinglight utilizes advanced SMT assembly lines and quality testing systems to produce high-precision PCBs in high volumes.

Heilind Electronics

Heilind Electronics is a multinational distributor of electronic components and PCBs. Their manufacturing facilities in China produce LED PCBs in prototype volumes or high-volume production runs. Heilind offers specialized LED PCBs optimized for street lighting, horticultural lighting and more.

Multek

Multek, part of the Chin Poon group, is a large flexible PCB and rigid-flex PCB manufacturer with production sites globally. Their state-of-the-art facility in Wuxi, China manufactures HDI (high density interconnect) PCBs for high-power LED applications.

San Francisco Circuits

San Francisco Circuits manufactures quick-turn prototyping, low volume, and production volume PCBs for LED applications in their ISO-9001 certified factory in San Francisco, USA. They produce 1-30 layer LED PCBs using advanced thermal management materials.

AT&S

AT&S is Europe’s largest PCB manufacturer, providing LED PCB solutions from their plants in Austria and India. They leverage their expertise in HDI PCBs to produce high-precision boards for LED lighting and automotive applications.

Shenzhen Topway Technology

Topway is an LED PCB manufacturer based in Shenzhen, China. For over 15 years, they have specialized in producing aluminum PCBs, ceramic PCBs, and other thermal boards optimized for the thermal demands of high-power LED systems.

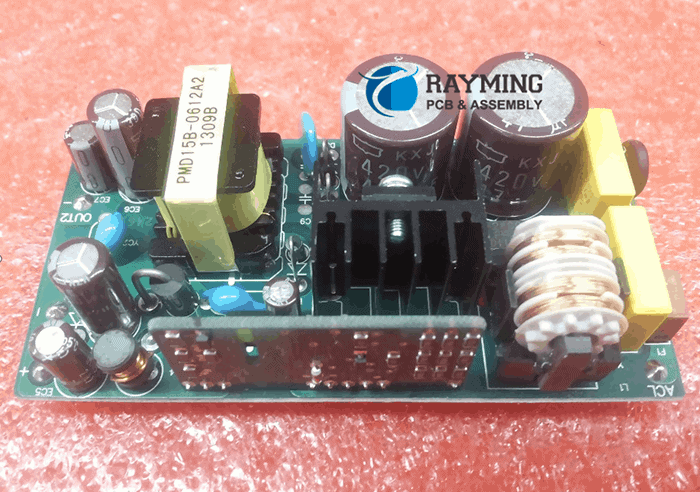

LED PCB Manufacturing Process

Producing PCBs for LED applications involves advanced fabrication processes tailored around the unique requirements of LEDs. Here are the key steps:

PCB Design

The PCB layout is carefully designed to accommodate LED positioning, thermal management, circuit requirements and electrical connections. Design software optimizes trace widths, hole sizes, copper weights and board layers.

Material Selection

Materials like aluminum or ceramic are chosen for optimal thermal conductivity to dissipate heat from high-power LEDs. The material must match the coefficient of thermal expansion of the LEDs.

Prototyping

Prototype boards are fabricated to verify the PCB design before full production. Engineers test the thermal performance, electrical connectivity, and reliability of the layout.

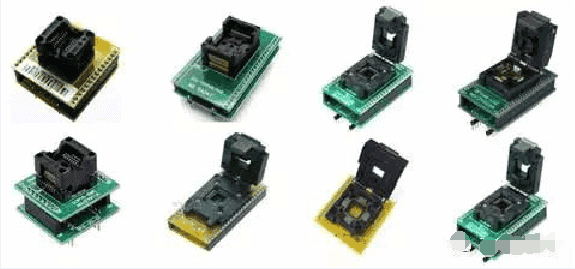

Surface Mount Technology (SMT)

SMT assembly lines place tiny LED components onto PCBs with high accuracy. Pick-and-place machines and reflow ovens solder components using surface mount technology.

Testing and QA

Finished boards undergo comprehensive testing, like flying probe testing, to ensure all traces have quality solder joints, meet circuit requirements, and function as intended.

Volume Production

Once the design is verified, LED PCBs are mass-produced using the complete fabrication and assembly process in high volumes.

Finishing

Additional finishing steps like PC routing, protective conformal coating and silk screening can be completed according to specifications.

Delivery

Finished PCBs are shipped to customers around the globe. Quality checks confirm order accuracy.

Key Design Considerations for LED PCBs

LED PCBs have unique design demands compared to standard PCBs:

- Thermal Management – Heat sinks, thermal pads/vias, and specialized board materials help dissipate heat from high-power LEDs.

- High Lumens – Extra layers and optimal copper weights manage increased current and power demands.

- Component Density – Compact PCB size requires precise component placement and routing for crammed layout.

- Standards Compliance – Meeting safety and performance standards for lighting applications requires robust design.

- Materials – Aluminum, ceramic and other thermally advantageous PCB materials accommodate LED thermal output.

- Current Capacity – Adequate trace sizes, copper weights, and board layers manage high amperage of LED arrays.

- Precision Manufacturing – SMT assembly with small component sizes and lead-free soldering is critical.

Trends in LED PCB Manufacturing

Some notable trends shaping LED PCB manufacturing include:

- ** Miniaturization** – Continued minimization of LED component sizes enables more compact and efficient PCBs.

- Higher Power – Increased lumen output of next-gen LEDs requires evolving thermal management on PCBs.

- Reliability Testing – Accelerated lifetime testing predicts long-term performance to validate robust PCB designs.

- Automation – Highly automated assembly with advanced optical inspection improves speed and accuracy.

- Smart PCBs – Integrating intelligence and controls onto the PCB enables more self-managed LED systems.

- Flexible PCBs – Flexible or bendable PCB materials allow for customized LED arrangements.

- Green Manufacturing – More sustainable, energy-efficient manufacturing techniques reduce environmental impact.

As LED technology progresses, LED PCB manufacturing will continue adapting to enable smaller, smarter, more powerful LED lighting solutions.

Frequently Asked Questions About Led Pcb Manufacturers

Q: What types of PCB materials are used for LED PCBs?

A: The most common PCB materials for LEDs are aluminum PCBs and ceramic PCBs due to their thermal conductivity and matched CTE with LED components. Other options include traditional FR-4, IMS, and thermal clad PCB materials.

Q: How are the LED components mounted and connected on a LED PCB?

A: SMT assembly lines use precision pick-and-place machines and reflow soldering to accurately position and solder miniature LED components onto PCBs via surface mount pads and lands.

Q: What are some key design elements for an LED PCB?

A: Critical design factors are thermal management features like thermal vias/pads, adequate layer count for power distribution, and appropriate trace widths for LED current demands. Most designs require careful component placement and routing.

Q: What types of testing are performed on LED PCBs?

A: LED PCBs typically undergo thermal profiling, flying probe electrical testing, functional testing under temperature extremes, vibration testing, and accelerated lifetime testing to validate design robustness.

Q: How fast can an LED PCB manufacturer deliver finished boards?

A: Lead times range from 24 hours for quick-turn prototypes to 8 weeks or more for complex, high-volume production PCBs. Rushed turnaround often costs extra depending on capabilities.

Conclusion

LED PCB manufacturing brings specialized demands in thermal management, component density, materials selection, and advanced manufacturing processes. By leveraging the expertise of experienced LED PCB companies, lighting manufacturers can develop innovative LED systems and products on optimized, high-performance PCB platforms engineered for this unique application.

0 Comments