Printed circuit boards (PCBs) are an essential part of most electronic devices and products. Choosing the right PCB company to manufacture your boards can have a big impact on your project’s success. This guide will walk you through the key factors to consider when selecting a PCB manufacturing partner.

What to Look for in a PCB Company

Quality

The quality of the PCBs produced is of utmost importance. Look for a company that:

- Uses high-grade materials and advanced manufacturing processes

- Has a low rejection and error rate

- Offers testing and inspection at multiple stages

- Is certified to quality standards like ISO 9001

Technical Capabilities

Consider the PCB specifications and complexity your project requires. Make sure the company has expertise in:

Layer Count

- Single or double sided

- Multilayer (4+ layers)

- HDI (high density interconnect)

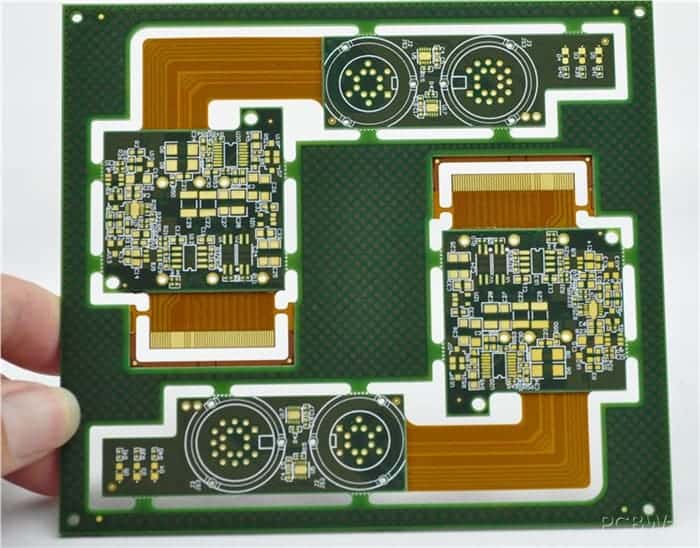

Board Type

- Rigid

- Flexible (flex)

- Rigid-flex

Size

- Small, medium, large

- Maximum dimensions

Materials

- FR-4, polyimide, ceramic, Rogers, etc.

Fabrication Tolerances

- Line width/spacing

- Annular rings

- Hole size/pitch

Manufacturing Scale

The company should have enough capacity, equipment, and staff to manufacture the quantity you need, within your timeframe.

Services

Look for a company that provides other helpful services like:

- Design for manufacturability (DFM) analysis

- Prototyping and low volume production

- Assembly and testing

- Supply chain management

Technical Support

They should have engineers to support you with design reviews, troubleshooting, and technical questions.

Communication and Responsiveness

Timely and proactive communication is key, especially if issues come up. Prioritize companies with great customer service.

Comparing PCB Manufacturers

Evaluating and comparing a few potential PCB partners is recommended. Here are some key considerations:

Location

Are they domestic or overseas? Shipping times and costs may be impacted.

Experience

How long have they been in business? Do they have experience with projects like yours?

Quality Certifications

What certifications have they achieved? Popular ones include:

- ISO 9001

- ISO 14001

- IPC Standards

- UL Approvals

Capabilities

Do they meet all your PCB requirements for materials, layers, tolerances, etc?

Volume Capabilities

Can they comfortably manufacture the quantity you need in your timeframe?

Pricing

Compare quotation pricing, discounts for volumes, additional costs, etc.

Reviews

Check online reviews and testimonials from past customers.

| Factor | Company A | Company B | Company C |

|---|---|---|---|

| Location | USA | China | USA |

| Years in Business | 10 | 5 | 15 |

| Certifications | ISO 9001 | ISO 9001, IPC-A-610 | ISO 9001, ISO 14001 |

| Capabilities | Meets requirements | Meets requirements | Meets requirements |

| Volume Capacity | High | Medium | High |

| Pricing | $$ | $ | $$ |

| Reviews | Positive | Mixed | Very Positive |

This table compares a few potential PCB manufacturers on some key criteria as an example.

The PCB Manufacturing Process

Understanding the complex process of manufacturing PCBs can help you communicate better with your chosen partner. Here are the key steps:

1. Design

Your Gerber files are assessed. The PCB company will perform design rule checks and offer design for manufacturability (DFM) feedback.

2. Prototyping

Initial test boards are fabricated to verify the design before full production proceeds.

3. Production Panelization

Boards are arranged efficiently on panels for mass production.

4. Materials Preparation

The layered board materials are prepared, including the copper foil, glass fabric layers, and substrate.

5. Imaging

Using lithography, the circuit pattern is imaged onto the layers.

6. Etching & Stripping

The copper is etched to form the traces, and a chemical stripping process removes the photoresist.

7. Layer Alignment & Lamination

Layers are precisely aligned and bonded together under high pressure and heat.

8. Drilling

Holes are drilled for vias and component leads to pass through.

9. Plating & Coating

Surfaces are plated with metals for conductivity and solderability. Protective coatings may be applied.

10. Solder mask

A layer is applied that coats the entire board except the soldering pads.

11. Silkscreen

Printed labels, markings, and legends are added for identification.

12. Testing & Inspection

Rigorous optical and electrical testing checks for defects.

13. Separation & Packaging

Boards are routed from the panels, inspected again, and packaged for shipping.

Understanding this complex manufacturing process can help you appreciate the value provided by a professional PCB company. It will also help you communicate any special requirements to them.

5 Key Questions to Ask Your PCB Manufacturer

When reaching out to potential PCB partners, make sure you get answers to these key questions:

1. Can you manufacture my boards according to these specifications?

Provide your complete PCB requirements – materials, layer count, tolerances, etc. Get confirmation the company can meet them.

2. What design for manufacturability feedback do you have?

Get their input on any improvements or tweaks to your design files that will aid manufacturability.

3. What lead times can you commit to?

Ask how long from order to delivery for both prototypes and volume production.

4. What testing and inspection processes do you have?

Understand their quality control procedures to catch defects and verify board function.

5. How do you ensure on-time delivery?

Check that they have systems in place to meet delivery promises and manage delays if any come up.

Getting the right PCB company on board is a key ingredient for bringing your electronics product from concept to reality. Following this guide will help you find the ideal manufacturing partner to meet your technical needs and deliver within budget and schedules. With diligent sourcing and comparisons, you’ll be able to entrust your PCB fabrication to a trusted partner.

Frequently Asked Questions

What are the typical layers in a PCB?

The most common PCB layer counts are:

- Single sided – Copper traces on one side only

- Double sided – Copper on both top and bottom sides

- Multilayer – Alternating layers of conductors and insulating dielectric material stacked up, most commonly 4-16 layers

How long does PCB manufacturing take?

For prototypes, production can be as fast as 24 hours. For volume production, standard lead times range from 5 to 15 days, depending on complexity and order quantities.

What file formats do PCB manufacturers need?

Gerber (.gbr) and drill (.drl) files are standard inputs for PCB fabrication. Many manufacturers also accept CAD data like ODB++.

Should I get a quote from multiple PCB companies?

Yes, it’s recommended to get 3-4 quotations to compare pricing. Be sure to provide each company the same information so quotes are on equal footing.

What questions should I ask PCB manufacturers?

You should ask about their capabilities, quality certifications, lead times, pricing, and manufacturing capacity. Also inquire about their design, prototyping, assembly, and testing services.

0 Comments