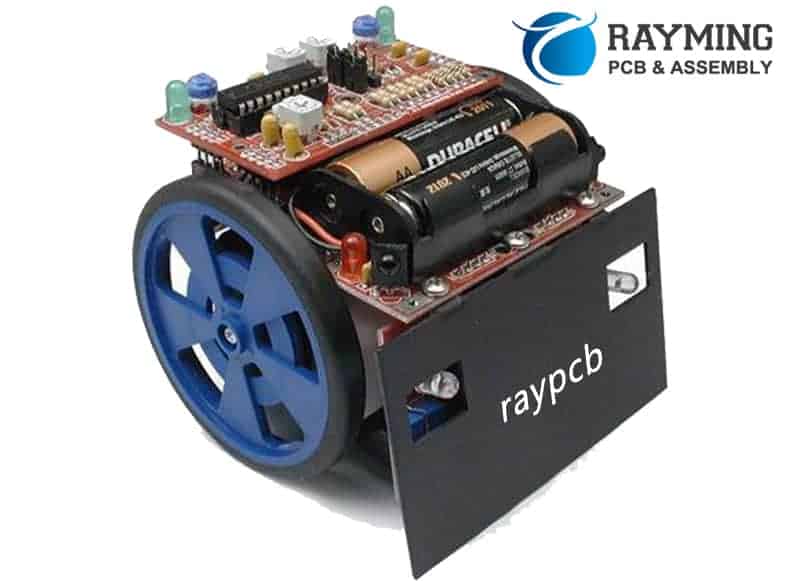

Developing a new electronic product requires repeated cycles of prototyping, testing, and refining the design. The faster each iteration goes, the quicker you can finalize the design and move to production. This is where rapid prototyping PCB assembly comes in.

Rapid prototyping involves assembling printed circuit boards (PCBs) with extremely fast turnarounds, often in just 24-72 hours. This accelerates the pace of prototyping by weeks compared to standard lead times.

Below we’ll explore the benefits of rapid prototyping PCB assembly, top service providers, cost tradeoffs, and best practices for streamlined results.

Benefits of Rapid Prototyping Services

Utilizing rapid assembly services for prototypes provides several advantages:

Faster Design Iterations

Ultra-quick turnarounds enable multiple cycles of building, testing, evaluating, and refining boards in parallel rather than sequentially. This compresses development timelines.

Early Performance Validation

Getting prototypes assembled in days verifies the design performs as intended and catches issues early before final release. This prevents problems late in the development process.

Enhanced Design Feedback

With boards in hand rapidly, more feedback can be gathered from multiple stakeholders on performance, usability, and other attributes to refine the product.

Accelerated Time-to-Market

The faster working prototypes can be produced, the quicker the product can be validated, certified, and launched ahead of the competition.

Immediate Design Verification

Rapid turns verify that the prototype matches the intended design quickly, ensuring the CAD model was translated to gerbers and built correctly.

Increased Flexibility

The ability to get boards assembled in days allows more design modifications and experimentation during development before finalizing the production design.

Manage Changing Requirements

Prototypes can be updated rapidly as requirements evolve without extensive rework or schedule impacts.

For projects with aggressive development timelines, utilizing rapid prototyping assembly maximizes the iterations possible within compressed schedules.

Top Providers of Rapid Prototyping Services

Many PCB assembly partners offer rapid prototyping services. Here are some of the top options:

Advanced Circuits

Advanced Circuits provides 48-hour PCB assembly turnaround out of their Colorado facility using an automated production line.

Imagineering

Imagineering offers 24-hour “blink of an eye” prototyping with online ordering convenience. They are located in Florida.

PCB Cart

PCB Cart delivers ultra-fast PCB assembly with their 48-hour Rapid Prototyping service out of their China facility.

Protocase

Protocase provides 24-hour CNC-based PCB prototyping and assembly services from multiple locations across North America.

ProtoExpress

ProtoExpress offers 5-day assembly of prototypes and pre-production boards from their California factory floor.

Screaming Circuits

Another domestic US option, Screaming Circuits builds prototypes in 5 days or rush 2-3 day service.

Sunstone Circuits

Sunstone Circuits has rapid prototyping and small-run production down to 72 hours out of their Oregon facility.

This is just a sample of reputable providers of rapid PCB assembly services tailored to prototyping needs. Make sure to compare multiple options.

How Much Does Rapid Prototype PCB Assembly Cost?

Costs vary based on board complexity, order size, and how fast the turn time is, but here are typical price ranges:

| Build Time | Prototype Order |

|---|---|

| 24 Hours | $250 – $800 |

| 48 Hours | $200 – $600 |

| 3-5 Days | $150 – $400 |

In general, expect to pay a premium of 2x standard rates or more for ultra-fast 24-48 hour service. However, some providers offer expedited 3-5 day assembly at more modest upcharges.

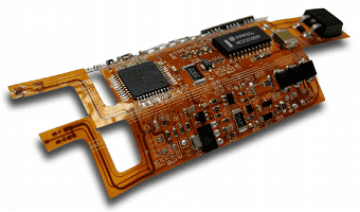

Factors like fine pitch components, BGAs, high layer counts, and FR4 vs. flex/rigid boards will increase prices as well.

Always get quotes from multiple vendors. Negotiate discounted rates for multiple-board orders and ongoing prototype projects.

Tips for Efficient Rapid Prototype Assembly

Follow these tips to ensure your rapid prototype orders go smoothly:

Use Dedicated Prototype Components

Maintain pre-sourced inventories of your most common prototype parts to avoid procurement delays each order.

Design with Standard Parts in Mind

Choose common 0603/0402 SMT packages from major suppliers when possible for easy sourcing.

Provide Complete Documentation

Have all assembly files, BOMs, gerbers, etc. ready to upload to minimize back and forth and potential miscommunication.

Share Designs Early for DFM Feedback

Engage your assembly partner while still designing for manufacturability feedback to avoid issues.

Order Extra PCBs

Order a few extra blank PCBs for advanced debugging and programming needs or in case boards are damaged during handling.

Leave Buffer in Schedules

Avoid promising prototypes on the very last day of a quoted lead time. Leave 1-2 days of cushion for the unexpected.

Validate Before Full Production

Confirm that one or two rapid prototypes are fully correct before proceeding to higher volume manufacturing.

Don’t Change Designs Mid-Order

Resist tweaking the design while a rapid turn order is already underway since changes can delay and complicate fast builds.

Following these best practices will help your rapid prototyping orders complete successfully within ultra-tight schedules to accelerate product development.

Should You Hand Assemble Prototypes?

For one-off validation builds, it may be feasible to hand assemble boards yourself rather than use full assembly services. This avoids setup/order costs but has tradeoffs:

Pros

- Lower cost for single boards

- Faster turn for simple designs

- Tweak designs mid-build

- Educational for assembling basics

Cons

- Very time consuming for complex boards

- More prone to errors without automation

- Difficult for fine pitch parts without precision equipment

- Delayed debugging until all parts placed

- No professional soldering, cleaning, or inspection

Hand assembly is worth exploring for simple board validation. But for professional results, leverage existing expertise and tools with rapid prototyping assembly services.

Conclusion

For projects operating on tight schedules, rapid prototyping PCB assembly services enable fast design validation and accelerated time to market. The ability to get working boards built and tested in just 24-48 hours rather than weeks compresses development time significantly.

However, ultra-fast assembly comes at increased cost. Carefully evaluate providers based on price, capabilities, location, quality, and ease of use. Provide optimized documentation and maintain standard component inventories. Build in schedule buffer and validate designs upfront to avoid delays during crunch times.

With the right planning and provider relationship, rapid prototyping assembly ensures you can refine and experiment more freely during development, spend more time on design quality rather than logistics, and ultimately deliver exceptional products faster to customers.

Frequently Asked Questions

Q: What is the fastest turnaround for assembled prototype PCBs?

A: The fastest assembly services deliver fully functioning boards in 24-48 hours. However, this is primarily for less complex designs and single unit quantities.

Q: What are best practices for rapid prototype assembly?

A: Engage early for DFM input, maintain standard part inventories, order extra boards, budget adequate costs, leave schedule buffer, and validate with a few units before full production.

Q: How much more does rapid assembly cost over standard turns?

A: In general, expect to pay at minimum 50% – 100% more for 24 hour service and 25% – 50% premiums for 48-72 hour rapid builds compared to 2-3 week standard assembly timeframes.

Q: Should I assemble my own prototypes by hand?

A: For simple boards, hand assembly may be suitable for initial validation but lacks repeatability at scale. For robust results, leverage assembly provider expertise, tools, and quality controls.

Q: What are the risks of rapid prototype assembly?

A: Faster scheduling increases risks like workmanship defects, part shortages, incomplete inspections, and design changes made mid-stream. Thoroughly vet providers and build in extra schedule cushion.

0 Comments