Rapid PCB Prototyping: A Guide to Faster Electronics Design

Prototyping is a crucial step in the electronics design process. A prototype allows designers to test concepts, evaluate functionality, and refine the product before final manufacturing. However, traditional prototype development and fabrication can be extremely time-consuming. Rapid PCB prototyping techniques can greatly accelerate the prototyping phase for faster design iteration.

This guide covers the key benefits of rapid PCB prototyping as well as the tools, technologies, and best practices to prototype printed circuit boards (PCBs) quickly.

Benefits of Rapid PCB Prototyping

The ability to test PCB designs quickly through rapid prototyping provides several advantages over traditional methods:

- Faster design iteration: Make changes and test new revisions in days rather than weeks.

- Early verification: Verify the PCB layout, component choice, etc. while the design concept is still flexible.

- Reduced development costs: Reduce the number of design spins and errors needing correction down the line.

- Shortened time-to-market: Get innovative products to market faster by condensing the development timeline.

In summary, rapid PCB prototyping can accelerate learning, reduce costs, and speed up development for a competitive advantage. Electronics companies today leverage various tools and techniques to enable faster iteration.

Rapid Prototyping Techniques and Tools

Several rapid PCB prototyping techniques can facilitate faster design iteration compared to traditional fabrication cycles:

PCB Design Software

Using PCB design software with features like real-time design rule checking helps create designs that are manufacturable the first time. Some examples are Altium Designer, Cadence Allegro, and KiCad.

Key features that enable faster PCB design:

- Native 3D visualization

- Design rule checking

- High-speed interfaces

- Version control and collaboration

By leveraging these features, PCB designers can identify issues early on and design quality boards faster.

Simulation Software

Simulation software helps verify circuit operation before building physical prototypes. Some examples are SPICE simulators, electromagnetic interference (EMI) solvers, and signal integrity analyzers.

Key capabilities of simulation software:

- Verify integrity of power delivery network

- Check signal timing, distortion, crosstalk, etc.

- Model heat dissipation and thermal management

- Analyze electromagnetic compatibility

Simulation enables engineers to refine the design upfront, reducing the need for additional prototyping iterations.

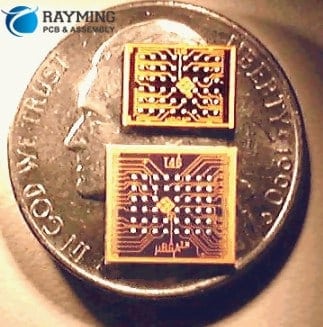

Prototyping Methods

Some PCB prototyping techniques that enable very fast fabrication include:

- DIY milling: Use a desktop CNC milling machine to fabricate PCBs from the design files.

- Laser direct structuring (LDS): Use a laser to activate plastic surfaces for creating conductive traces in a single step.

- 3D printing: Use conductive inks or conductive filaments to 3D print a PCB prototype.

While DIY methods trade off some quality, they empower designers to build prototypes in hours/days rather than relying on external fabrication.

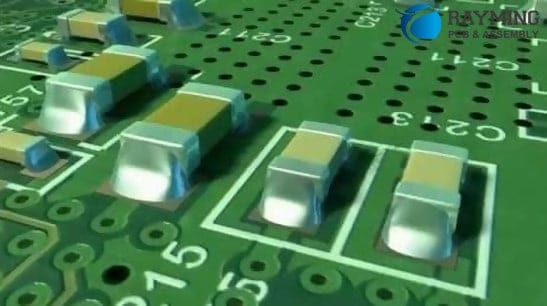

PCB Assembly Services

To complement rapid PCB prototyping, using an assembly service speeds up population of a prototype board with components. Some options are:

- Hand assembly: Assemble smaller quantities of prototypes manually.

- Machine assembly: Leverage automated pick-and-place for higher-volume prototypes.

- QUICK-TURN assembly: Use expedited assembly with 24-48 hour turnaround.

With assembled prototypes in hand, designers can move quickly from bare PCBs to full system testing.

Best Practices for Rapid Prototyping

To fully leverage the above tools and techniques for rapid PCB prototyping, keep in mind some best practices:

- Start PCB layout early, even while still defining schematics, to gain time.

- Use design reuse by creating modules and templates of proven logic blocks.

- Keep prototypes simple; minimize complexity until later stages.

- Order assembly stencils upfront for faster population once boards are fabricated.

- Build in testing points on the PCB to validate functions without instrumentation.

- Assign more layout resources to accelerate complex routing jobs.

- Validate manufacturability by contacting fabricators while designing.

- Plan early involvement of manufacturing/supply chain to support rapid iteration.

With the right approach, skilled engineers can now compress PCB prototyping schedules from months down to weeks or even days.

When to Use Rapid Prototyping vs. Traditional Methods

While rapid prototyping enables huge gains in development speed, it is not ideal for every situation. Traditional, slower fabrication methods are better suited when:

- High reliability and performance are needed for product release.

- Mass production and economies of scale outweigh time-to-market.

- Tight tolerances, high complexity, or advanced processes are used.

- Compliance testing like UL certification is required.

- Extreme environmental resilience needed for aerospace, defense, etc.

For these cases, rapid prototyping is still useful during initial concept verification, before switching to traditional qualified methods for final products.

Conclusion

Rapid PCB prototyping techniques empower engineers to achieve staggering improvements in development speed over older methods. By embracing advanced tools for design, simulation, DIY fabrication, and quick-turn assembly, companies can test concepts faster for reduced costs and accelerated time-to-market. With the right approach, PCB prototyping can keep pace with today’s iterative, agile hardware development processes.<h2>FAQ</h2> <details> <summary>What are some key benefits of rapid PCB prototyping?</summary> <ul> <li>Faster iteration allows testing design changes quickly instead of long fabrication lead times.</li> <li>Early verification during flexible design stages prevents costly mistakes.</li> <li>Reduced prototyping costs by minimizing unnecessary iterations.</li> <li>Shorter development timeline allows innovating and releasing new products faster.</li> </ul> </details> <details> <summary>What tools help enable rapid PCB prototyping?</summary> <ul> <li>PCB design software with real-time DRC, 3D view, version control.</li> <li>Simulation software to model circuits, thermal issues, signal integrity.</li> <li>DIY milling machines, 3D printers, laser structuring to prototype in hours/days.</li> <li>Quick-turn assembly services to quickly populate prototypes.</li> </ul> </details> <details> <summary>What are some best practices when doing rapid prototyping?</summary> <ul> <li>Start PCB layout early so fabrication can begin as soon as possible.</li> <li>Use proven design modules/templates for faster implementation.</li> <li>Keep initial prototypes simple and minimalistic.</li> <li>Get assembly stencils upfront to enable fast population.</li> <li>Include test points on the board for easy troubleshooting.</li> </ul> </details> <details> <summary>When is traditional fabrication better than rapid prototyping?</summary> <ul> <li>When highest performance, reliability and strict tolerances are required.</li> <li>For high-volume mass production where time-to-market is less critical.</li> <li>Where rigorous compliance testing is needed before release.</li> <li>In extreme environments like aerospace/defense applications.</li> </ul> </details> <details> <summary>What is the main conclusion about rapid PCB prototyping?</summary> <p>Rapid prototyping techniques like advanced PCB software, simulation, DIY fabrication and quick-turn assembly enable vastly faster iteration cycles compared to traditional methods. This allows companies to innovate, test concepts, reduce costs, and release new products faster.</p> </details>

0 Comments