Introduction

Printed circuit boards (PCBs) are essential components of most electronic devices today. While large manufacturers can produce PCBs in high volumes at low costs, small and medium businesses often only require small prototype or low volume production runs. Working with a PCB manufacturer experienced in small quantity orders enables bringing your product to market faster and more affordably.

What is Low Volume PCB Production?

Low volume PCB production typically refers to orders for about 10-100 printed circuit boards or fewer. This allows companies to prototype designs, verify concepts, and conduct testing before investing in larger production runs. Key characteristics of low volume PCB production include:

- Smaller order quantities – 10, 25, 50 or 100 PCBs

- Faster lead times – Often 5-10 days

- More flexible design options

- Lower startup and tooling costs

Low volume production is ideal for verifying a design before full scale manufacturing. It also supports limited runs for niche products that may never require thousands of PCBs.

Benefits of Using a Small Quantity PCB Manufacturer

Working with a PCB company specializing in low volume orders offers important benefits:

Faster Lead Times

By focusing on small orders, these suppliers can often deliver in 5-10 days. This enables rapid prototyping and testing of new ideas.

Lower Startup Costs

The fixed costs of setting up a PCB fabrication line for a particular design can be high. By concentrating on small orders from many customers, the setup costs are shared across more boards.

Flexible and Custom Services

Since small manufacturers are not running high volume production, they can offer more flexible services. This includes:

- Supporting more PCB substrate materials

- Utilizing a broader range of components

- Offering quick turn iterations and modifications

Personalized Service

Low volume manufacturers provide a more customized service experience. They work closely with the customer to understand requirements and provide technical advice.

Lower Costs

While per unit costs are higher than large volume production, total costs can be much lower due to reduced overhead and minimum order quantities. This makes small scale production more accessible.

Capabilities of a Small Quantity PCB Producer

To deliver quality boards even in small numbers, manufacturers must have a diverse range of capabilities:

- Engineering Expertise – With knowledge to assess customer designs and make recommendations if needed.

- Prototype Services – For turning concepts into physical PCBs quickly.

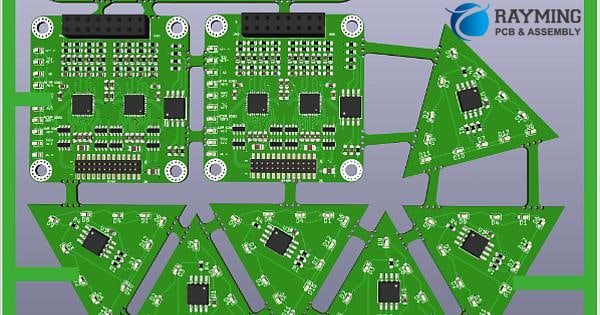

- Flexible Manufacturing – That can produce 10 to 100 boards efficiently from a wide variety of materials.

- Testing and Quality Control – To verify board performance and reliability.

- Assembly Services – From manual assembly to automated pick-and-place and soldering.

- Logistics Assistance – To handle programming, shipping, customs and delivery.

This range of services enables the PCB producer to support customers through the full cycle from early prototyping through to small scale finished product runs.

Common Capabilities of Low Volume PCB Manufacturers

| Capability | Description |

|---|---|

| Engineering Expertise | Knowledge to evaluate designs and make recommendations |

| Prototype Services | Rapidly produce initial board concepts |

| Flexible Manufacturing | Produce 10-100 boards from various materials |

| Testing/Quality Control | Verify board performance and reliability |

| Assembly Services | From manual assembly to automated production |

| Logistics Assistance | Handle ordering, shipping and delivery |

Evaluating Small Quantity PCB Manufacturers

When selecting a low volume PCB producer, key factors to consider include:

- Cost – Request quotes for your specific order to compare pricing.

- Lead Times – How quickly can they deliver on small orders?

- Quality Processes – Do they follow industry quality standards?

- Capabilities – Do they offer the services you need?

- Materials/Components – Do they work with your required materials and parts?

- Customer Service – Do they provide engineering support and design assistance?

- Location – Where are they geographically located? Can they support global shipping?

By evaluating vendors across these criteria, you can select a partner able to fulfill your requirements at a reasonable cost.

Key PCB Manufacturer Selection Criteria

| Criteria | Importance |

|---|---|

| Cost | Get quotes for comparison |

| Lead Times | How fast for small orders? |

| Quality Processes | Follow industry standards? |

| Capabilities | Offer required services? |

| Materials/Components | Support needed parts? |

| Customer Service | Offer design support? |

| Location | Where are they located? Global shipping? |

The PCB Manufacturing Process for Low Volumes

Even with small orders, PCB fabrication involves several steps:

1. Design Creation

The PCB design is developed based on requirements, usually using CAD software. This generates Gerber files containing circuit board layout data.

2. Order Processing

The customer uploads Gerber files to the manufacturer and finalizes order details. This defines size, layers, materials, quantities, delivery, testing needs, etc.

3. Engineering Review

The PCB company examines the design to ensure manufacturability. Recommendations may be provided to improve fabrication or performance.

4. Prototyping

For new designs, one or more prototypes may be produced to test the design before full production. Feedback can be incorporated into later versions.

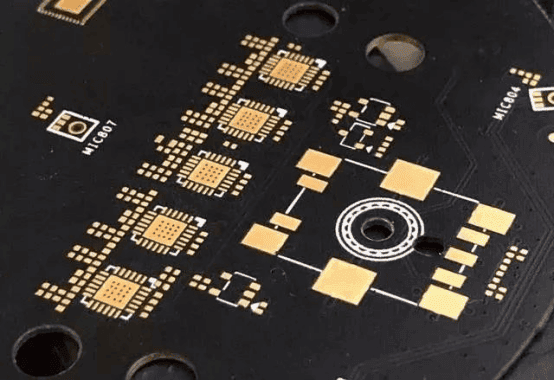

5. Fabrication

The PCB manufacturer uses Gerber files to produce the circuit board quantities ordered. Steps include substrate preparation, imaging, etching, hole formation, plating, and finishing.

6. Testing/Inspection

Boards are put through testing and optical inspection to verify quality and catch potential defects. Electrical testing validates connectivity and function.

7. Delivery

Finished boards are shipped via the customer’s preferred carrier. Air freight is typical for accelerated delivery.

Careful execution of each stage leads to higher yields and reliability even for low volume orders.

FQA (Frequently Questions and Answers)

What are the main advantages of using a small quantity PCB manufacturer?

The main advantages are faster lead times, lower costs, greater design flexibility, and custom services compared to large volume fabrication. Small manufacturers can deliver prototypes and limited production runs much quicker and more affordably.

What is the typical range of quantity for a small production run?

Small production runs typically range from 10 to 100 printed circuit boards. However, some manufacturers may accommodate even smaller quantities of just a few boards for prototyping needs.

Can small quantity manufacturers deliver good quality?

Yes, a competent low volume manufacturer will utilize the same fabrication and inspection processes as a high volume producer. The only difference is smaller batch sizes. With careful quality control, small runs can achieve excellent yields and reliability.

What are reasonable delivery timeframes to expect?

For order quantities under 50 boards, delivery can often be achieved in 5-10 working days. Larger orders up to 100 boards may take 10-15 days depending on materials and complexity. Expect longer times for new designs versus subsequent iterations.

How much higher are per unit costs compared to high volume orders?

As a rough estimate, per board pricing may be 5-10 times higher for order quantities under 25 units. The multiplier decreases as quantity increases. However, small orders avoid large fixed setup charges, so total cost can still be reasonable.

Summary

Partnering with an experienced small quantity PCB manufacturer enables startups and smaller companies to bring electronic products to market quickly and cost-effectively. These providers offer rapid prototyping, low startup costs, design flexibility, and personalized service not achievable with high volume fabrication. By selecting a vendor equipped to deliver high quality boards in small batches, innovative ideas can be transformed into tested and verified designs ready for production. Careful comparison of cost, capabilities, quality, and services will lead to finding the right partner for your unique needs.

0 Comments