Introduction

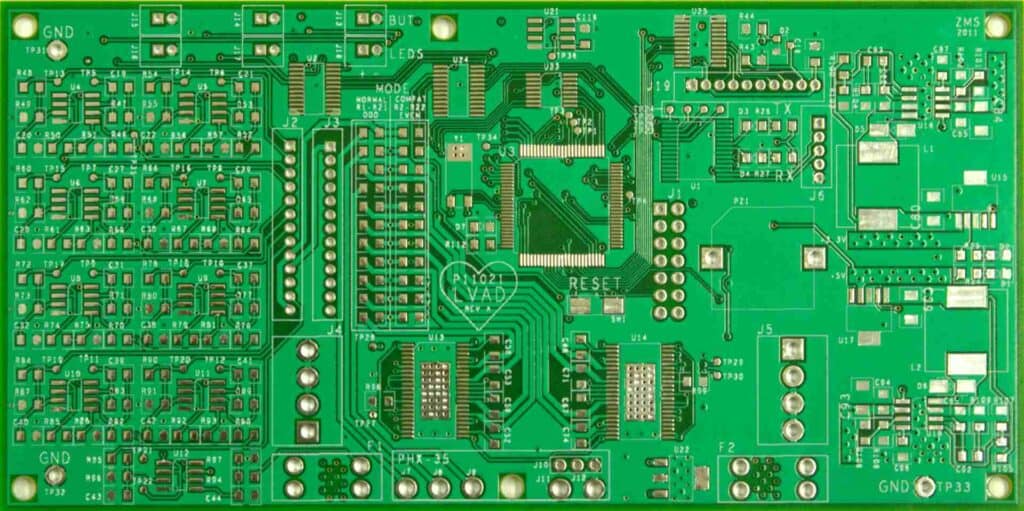

Printed circuit boards (PCBs) are at the heart of electronics hardware products. For prototyping and low-volume production, engineers and designers often want the most affordable PCB fabrication options. This article will explore the key factors to consider when selecting the cheapest online PCB manufacturers.

We will compare and analyze the pricing, capabilities, and tradeoffs of various budget-friendly PCB fabrication sources available to makers and entrepreneurs.

What to Look for in a Low-Cost PCB Fab

When evaluating potential low-cost PCB manufacturers, keep the following parameters in mind:

- Pricing model – Some offer fixed bulk pricing while others charge per quantity.

- Base pricing – Compare base per-board pricing for a given design to shortlist cheap options.

- Minimum order quantity – Many limit cheap rates to orders above their MOQ.

- Shipping charges – Some offer free shipping to certain regions for high-quantity orders.

- Quality – Review output quality as the cheapest options sometimes compromise on quality.

- Design rule limits – Check if their design rules match your required PCB capabilities.

- lead times – Expect longer lead times from budget fabs due to high volumes.

- Customer support – Look for fabs with responsive customer service for any production issues.

By balancing these parameters, you can zero in on manufacturers offering the optimal mix of affordability and capabilities for your specific needs.

Online PCB Manufacturers with Low Cost Options

Here is an overview of some well-known online PCB fabrication companies that offer highly competitive pricing suitable for budget-conscious buyers:

PCBWay

- Ultra low prices for single boards

- Free DFM checks to avoid errors

- Starts at $5 for 10 boards, $4.90 for 50 boards

JLCPCB

- Known for very low base pricing

- MOQ of just 5 boards

- Bulk pricing as low as $2.50 per board

RAYMING PCB

- Affordable rates for hobbyists

- Single boards under $20

- Free solder stencil at 10 boards

EasyEDA

- Integrated PCB design and fab quoting

- Base rate of $14.90 for 10 boards

- Budget assembly service available

This table summarizes the base pricing for these budget-friendly fabs:

| Manufacturer | MOQ | Price (10 boards) |

|---|---|---|

| PCBWay | 10 | $4.90 |

| JLCPCB | 5 | $2.00 |

| RAYMING PCB | 1 | $22.00 |

| EasyEDA | 1 | $14.90 |

Comparing Pricing Models of Online PCB Fabs

One key factor that influences overall board pricing is the cost model used by the manufacturer:

Fixed Bulk Pricing

Many fabs offer a fixed per-board price for bulk orders above a minimum quantity. Once you exceed the MOQ, each additional board is the same fixed price. This allows greater predictability in budgeting.

Examples – PCBWay, JLCPCB, ALLPCB

Per Quantity Pricing

For per quantity pricing, the per-board cost reduces in steps as order quantity increases. So a 100 board order will have a lower cost than 50 boards for example.

Examples – EuroCircuits, Imagineering

Hybrid Pricing

Some fabs use a hybrid approach, with fixed bulk pricing combined with a per quantity model. The pricing steps down at certain quantity tiers.

Examples – Seeed Studio Fusion PCB, WellPCB

Understanding these pricing models helps you optimize cost by ordering quantities to qualify for cheaper bulk or tiered pricing.

Factors That Contribute to PCB Cost

Below are some key design and fabrication factors that determine the overall board cost:

Board layers – Layer count directly impacts fabrication complexity. Additional layers increase costs.

Board size – Large boards use more materials, so cost more than compact boards.

Lamination – Special lamination like 1.6mm+ thickness and metal backing add expense.

High frequency design – Controlled impedance, tight tolerances, and impedance matching drive up cost.

Special materials – FR4 alternatives like Rogers, polyimide, ceramic cost multiple times more than standard FR4 substrates.

Special finishes – ENIG, immersion silver, and gold plating over standard HASL or lead-free finishes.

Panel utilization – Effective panel layout to maximize boards per panel reduces cost.

Certifications – UL, IPC, ISO, and RoHS add testing and process costs.

Lead time – Priority rush fabrication service has upcharges over standard lead times.

Cost Optimization Tips

Here are some tips to design and fab your PCBs in the most cost-effective manner:

- Choose budget-oriented fabs – Compare pricing between manufacturers and use the most affordable option.

- Maximize panel efficiency – Optimize board outlines and panel layout to maximize boards per panel.

- Use standardized design rules – Avoid any exceptions to fab’s design rules which add complexity.

- Go with FR4 material – Upgrade to higher grades like Rogers only if mandatory for performance.

- Minimize layers – Stick to 2 layers if possible, or 4 layers if routing is complex.

- Combine orders – Whenever possible, batch together PCBs from multiple projects to aggregate quantities.

- Order larger quantities – Take advantage of volume discounts beyond MOQ requirements.

Quality and Tradeoffs of Cheap PCB Fabs

While selecting the most affordable PCB manufacturer, you also need to match their capability tradeoffs to your prototyping needs:

Design complexity – Cheap fabs may have stricter design rules. Evaluate if your board layouts are compatible.

Quality – Some budget fabs compromise on consistency and precision relative to premium fabricators.

Lead times – Expect longer turnaround times from value-focused fabs due to high order volumes. Plan accordingly.

Flexibility – Cheap fabs offer less customization in fabrication processes and materials provided.

Support – You may experience slower response on technical queries and production issues.

Geographic location – Low cost fabs are usually based out of China, so factor in longer shipping times.

While inexpensive fabricators offer huge value, it is wise to test out production of a pilot batch first before committing bulk orders if you have not used them previously.

When Low Cost May Not be the Best Option

While cost is a major driving factor in choosing a PCB manufacturer, it is not always the ideal priority. Here are scenarios where a more premium fab may be preferable:

- Advanced or complex designs – If your boards demand tight tolerances, exotic materials, or high layer counts, premium fabs are better equipped.

- Low-volume orders – For prototyping just 1-5 boards, established fabs offer similar low rates without MOQ needs.

- Rush orders – When you need boards fabricated in 3-5 days, domestic premium fabs may provide faster turnaround.

- High-reliability requirements – For mission-critical boards that demand stringent testing and quality control.

- ITAR or other regulatory constraints – If your designs have export control restrictions or need to be fabricated domestically.

While cost is undoubtedly the biggest decision factor for most hobbyists and hardware startups, for more advanced or niche requirements, it is prudent to use qualified premium fabrication partners even at higher prices.

Frequently Asked Questions

Are cheap PCB manufacturers reliable for commercial products?

The large high-volume fabs in China offer surprisingly good quality and yields at aggressive pricing. Just order samples first to verify their capabilities match your needs.

What design factors contribute most to increased costs?

Layer count, board dimensions, special materials, and high-frequency design requirements contribute most to raising the PCB cost. Keeping design simple reduces cost.

Can I get discounts from online PCB fabs?

Yes, many will offer modest discounts of 5-10% if you order in bulk or agree to share your project details in their marketing. It never hurts to politely ask!

How much does PCB shipping cost factor in?

For lightweight PCBs, shipping is a small portion of total cost. To avoid shipping charges, use domestic fabs for very fast turnaround.

What are typical PCB lead times from China?

Standard lead times from large China-based fabs is usually 15-20 days. This can go up to 25+ days during peak seasons.

0 Comments