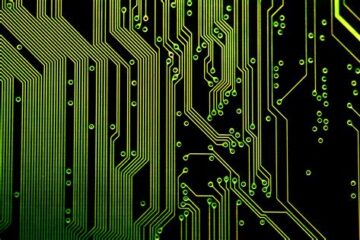

PCBA

ELECTROMECHANICAL ASSEMBLY

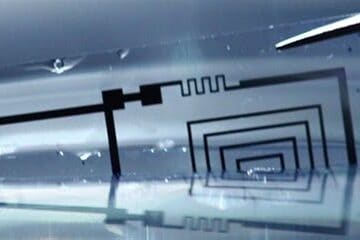

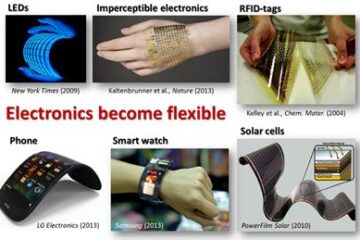

Introduction to Electromechanical Assembly Electromechanical assembly involves integrating electrical components with mechanical parts and systems to create functional devices and equipment. This process combines elements of electrical engineering, mechanical engineering, and manufacturing to produce a wide range of products, from consumer electronics to industrial machinery. Electromechanical assembly technicians play a crucial role in bringing these products to life by assembling, testing, and troubleshooting various components. Their work requires a deep understanding of electrical circuits, mechanical Read more…