PCBA

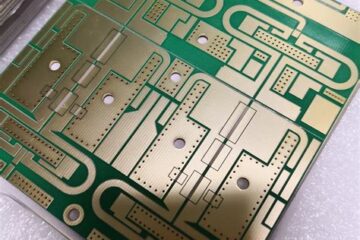

What are through holes on a PCB?

Introduction to PCB Through Holes Printed Circuit Boards (PCBs) are essential components in modern electronics, providing a platform for mounting and connecting various electronic components. One of the key features of PCBs is the presence of through holes, which play a crucial role in the assembly and functionality of electronic devices. In this article, we will delve into the world of PCB through holes, exploring their types, manufacturing processes, advantages, and applications. What are PCB Read more…