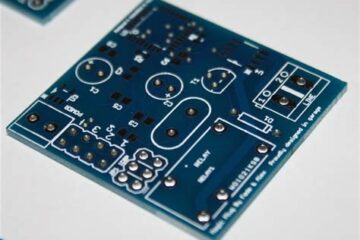

PCBA

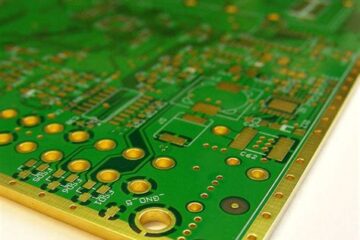

Homemade PCB: DIY PCB Board for Beginners

Introduction to DIY PCB Boards Are you fascinated by the world of electronics and eager to create your own custom printed circuit boards (PCBs)? Look no further! In this comprehensive guide, we’ll walk you through the process of making your very own PCB Board from scratch. Whether you’re a hobbyist, a student, or simply curious about the inner workings of electronic devices, this article will provide you with the knowledge and tools to embark on Read more…