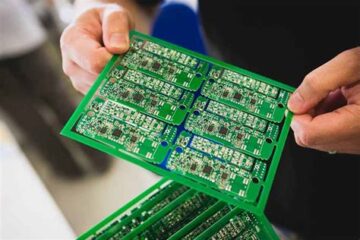

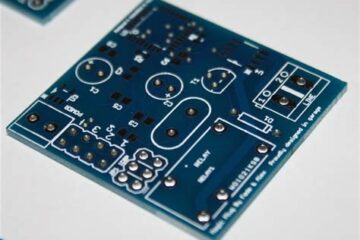

PCBA

PCB impedance calculator

Understanding PCB Impedance Printed Circuit Board (PCB) impedance is a crucial factor in designing high-speed electronic circuits. It plays a vital role in ensuring signal integrity and minimizing signal distortion, reflections, and crosstalk. PCB impedance is determined by various factors such as the geometry of the trace, the dielectric constant Read more…