Printed circuit boards (PCBs) constitute the core foundation of electronics packaging, interconnecting various components using etched copper traces and drilled holes on an insulating substrate. With electronics manufacturing heavily reliant on imported PCBs, China has established itself as the foremost global supplier meeting over 50% of worldwide demand over recent decades.

Attractive pricing, quick delivery and quality levels on par with western counterparts drive the dominance, especially for highly competitive consumer electronics and information technology verticals. This guide covers key considerations involved when looking to order PCBs from China:

Rise of China’s PCB Industry

China established an early foothold around the PCB supply chain encouraged by lower costs and favorable policies to drive exports. This allowed investing heavily in advanced manufacturing technologies supported through acquisitions and partnerships while exploiting domestic circuit design resources.

The last decade witnessed consolidation with competitive survivals attaining substantial economies of scale and capabilities covering quick-turn prototypes to high density multi-layer boards. Stringent quality benchmarks get maintained through process audits and certifications like UL, ISO, IATF 16949 system compliance.

Result is China currently produces majority share of global PCBs spanning all classification types – single sided, double sided, multi-layer, HDI (High density interconnects), rigid flex PCBs etc. Established infrastructure satisfies needs across market segments with access to latest fabrication technologies.

Pros and Cons of Chinese PCB Sourcing

Sourcing PCBs from China offers attractive advantages but also comes with few inherent challenges to weigh:

Pros

- Cost effective solution with scale economies

- Faster delivery over batch production capabilities

- Broad range of fabrication and assembly options

- Process and quality compliance assurances

Cons

- Communication difficulties with language gaps

- Cultural barriers around design subtleties

- IP protection concerns over data security

- Logistics lengthen delivery timelines

While pricing merits drive most PCB sourcing from China, thoughtful supplier selection and working to establish long term partnerships helps overcome drawbacks unlocking the full values.

PCB Specifications and Requirements

Comprehensively specifying product requirements constitutes the first step for any PCB order. This encompasses:

Electrical

- Schematics detailing component connectivity

- PCB layout files specifying physical designs

- Stackup layer sequences and dielectric materials

- Desired impedance traces with tolerance needs

- High speed constraints like edge rates, losses

Mechanical

- Board thickness, sizes, outlines and finishes

- Layer count, copper weights, compositions

- Hole diameters – vias, through holes, slots

- Component placements, clearances

- Special requirements like edge plating, countersinks

Testing

- ICT (In-circuit test) criteria if needed

- Functional testing coverage expectations

- DEF STAN standards for reliability

Delivery

- Order volumes with tolerances

- Target delivery days after order receipt

Quantitative requirements leave minimal ambiguity during procurement interactions. Include prioritized classifications helping tradeoff decisions if necessary.

Supplier Evaluation and Selection Factors

Prospective PCB suppliers undergo rigorous assessment across:

Technical

- Capabilities matching application needs

- Equipment, technologies facilitating specifications

- Staff engineering expertise assuring quality

Quality

- International certifications held

- Process audits compliance scores

- Customer product line survey for consistency

Commercial

- Budget alignments and cost structures

- Payment/contract terms flexibility

- Logistics facilities speeding customs clearing

Post-sales

- Design support extending capabilities

- Reiterative policy on rectifying issues

- Change management during order execution

Samples procurement, site visits and customer references further verify claims before engagement. Startups benefit through incubator programs getting preferential services.

Order Process, Production Monitoring

Standard sequence follows for executing orders:

Order Placement

Official purchase orders raised against negotiated quotations with approved engineering documentation. Order acknowledgements follow confirming all specifics.

CAM Data

- Computer aided manufacturing (CAM) files supplied for fabrication

- Data undergoes quality checks as input to photoplotting

Progress Updates

Periodic updates around milestones through staged production execution to match targets:

- Materials confirmation

- Base board processing

- Solder mask, legend printing steps

- Testing validations

- Finishing and metalization

- Final testing and packaging

Inspections Photos, in-process inspection reports assure quality with recourse to rectify issues like blemishes, inconsistencies early.

Quality Checks Before Acceptance

Prior to formal order completion and payment terms closure, PCB deliveries undergo vetting:

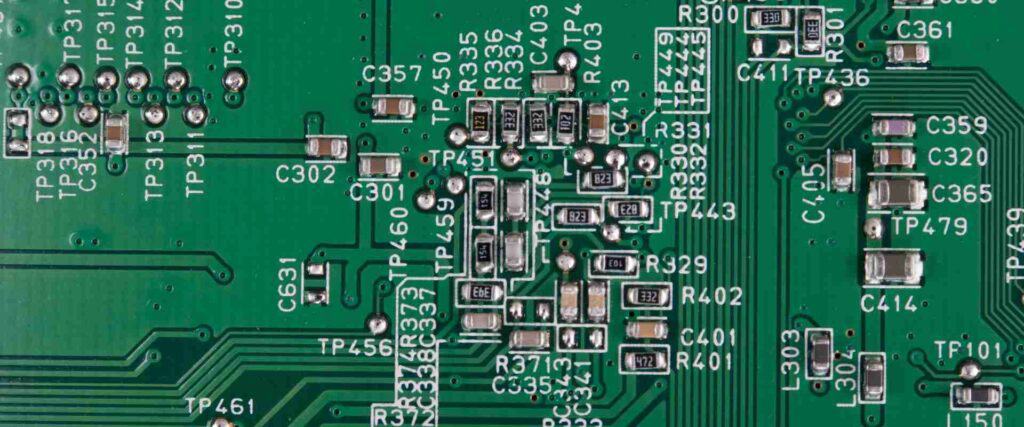

Visual Checks

- Ensure boards match specifications in terms of sizes, colors and finish

- Verify quality standards through magnified visual criteria

Dimensional Inspection

- Sample profiling of measured hole diameters, annular rings, etc

- Validate conformance to IPC-A-600 Acceptability of Printed Board standard

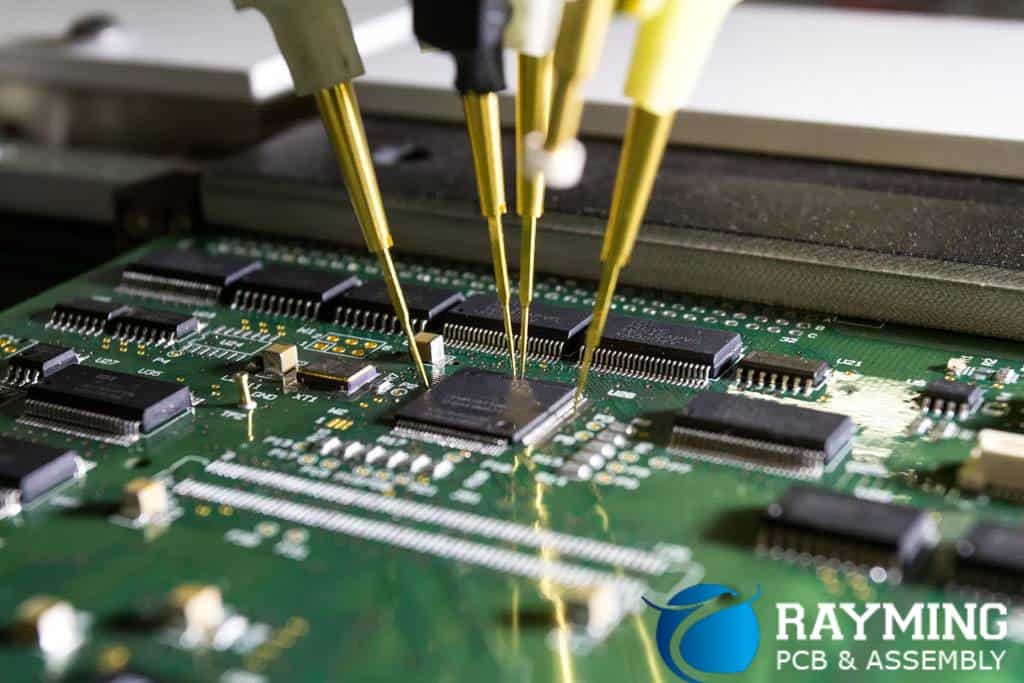

Netlist Testing

- ICT probes nets connectivity between nodes detecting opens or shorts

- Analog signature measurements assess impedance matches

Functional Testing

- Validate working operationally for intended application

- Stress testing corners performance including thermals, vibrations etc

Only passing these acceptance criteria culminates procurement formalities between customer and PCB supplier to establish satisfactory delivery.

Conclusion

Sourcing from Chinese partners provides tried advantages around affordability, quick delivery and range of technology options for printed circuit boards manufacturing. Clearly specifying quantitative requirements followed by diligent qualification of supplier capabilities ensures successful engagement. Multi-stage reviews during order execution coupled with extensive quality assurance testing gates effective transfer before final validation under real world operating conditions. With electronics intricacy constantly raising complexity needs, focused competencies by regional specialists likely sustain collaborations extracting mutual benefits between international supply ecosystems.

Frequently Asked Questions

What caused the PCB industry to flourish substantially in China?

Contributory circumstances enabling China’s PCB industry rise include:

- Access to latest manufacturing technologies

- Favorable export policies and cost structures

- Extensive skill pool around circuit design and fabrication

- Strong infrastructure and clusters spanning supply chain

What verification methodology validates quality from Chinese PCB suppliers?

Multi-pronged qualification aspects encompass:

- International certifications like IPC, ISO

- Process audits for standards adherence

- Initial sample vetting through testing

- Customer surveys on consistency

What measures ensure data security when supplying China PCB firms?

Protecting IP and securing data involves:

- Encrypted design data transfers

- Watermark schematics before sharing

- Non-disclosure agreements

- Restricting access through file permissions

How can language barriers be minimized working with Chinese PCB suppliers?

Bridging language gaps with PCB vendors uses:

- Technical translators for specifications

- Design reviews relying on visual markups

- Conversing through mobile applications

- Very quantified requirements

What precautions prevent issues around Chinese PCB delivery times?

Logistics delays get avoided by:

- Sea shipments buffering extra duration

- Air shipments for accelerated transits

- Tracking portal visibility

- Local warehousing streamlining customs

0 Comments