PCBA

Board Plating and Hole Plating

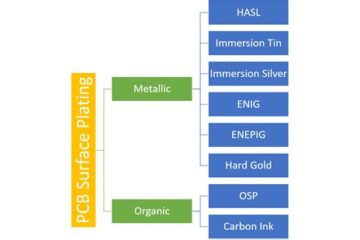

Introduction to PCB Plating Printed Circuit Board (PCB) plating is an essential process in the manufacturing of electronic devices. It involves the deposition of a thin layer of metal onto the surface of the PCB to improve its electrical conductivity, durability, and solderability. PCB plating is crucial for ensuring the proper functioning and reliability of electronic components and circuits. Types of PCB Plating There are several types of PCB plating, each with its own unique Read more…