PCBA

Wire Harness Manufacturing Process – A Step by Step Guide

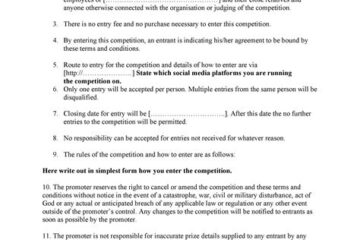

Introduction to Wire Harness Manufacturing Wire harness manufacturing is a crucial process in various industries, such as automotive, aerospace, and electronics. A wire harness, also known as a cable harness or wiring loom, is an organized assembly of electrical cables, wires, and connectors that transmit signals or electrical power throughout a vehicle, aircraft, or other electrical system. The manufacturing process of wire harnesses involves several steps, each requiring precision, accuracy, and attention to detail. In Read more…