PCBA

Why Start-ups or Small Businesses Should Choose Full Turnkey PCB Assembly?

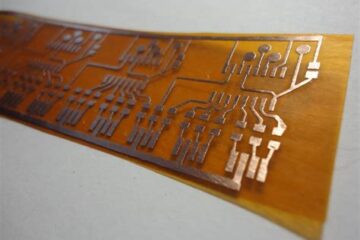

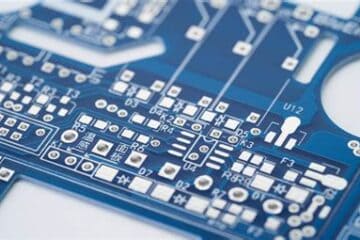

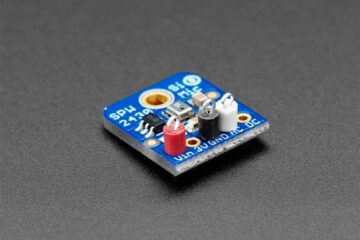

What is Full Turnkey PCB Assembly? Full turnkey PCB assembly is a comprehensive service that handles the entire PCB manufacturing process from start to finish. It includes: PCB design and layout Component sourcing and procurement PCB fabrication Component placement and soldering Testing and quality control Packaging and shipping With full turnkey PCB assembly, start-ups and small businesses can outsource the entire process to a single provider, simplifying the supply chain and reducing the burden on Read more…