PCBA

Why is PCB component orientation important in circuit board manufacturing?

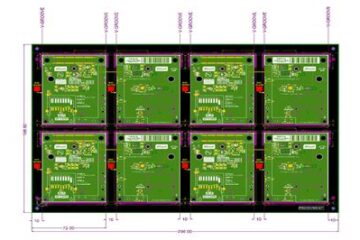

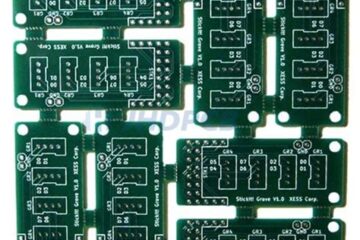

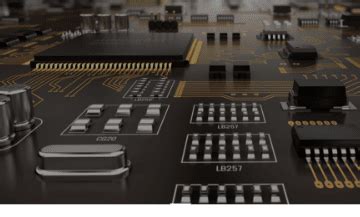

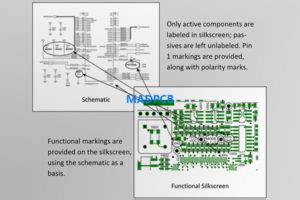

What is PCB orientation? PCB orientation refers to the placement and alignment of components on a printed circuit board. It involves determining the correct position and direction of each component, taking into account factors such as electrical connections, thermal management, and mechanical constraints. Types of PCB Orientation There are two main types of PCB orientation: Through-hole orientation: Components with leads are inserted through holes drilled in the PCB and soldered on the opposite side. Surface-mount Read more…