PCBA

Military PCB Fabrication Companies

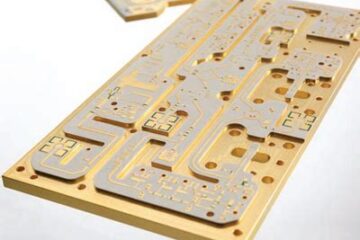

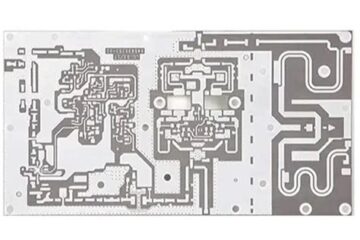

What are Military PCB Fabrication Companies (MPCBFC)? Military PCB Fabrication Companies (MPCBFC) are specialized manufacturers that produce printed circuit boards (PCBs) for use in military applications. These companies adhere to strict quality standards and regulations set by the defense industry to ensure the reliability, durability, and performance of their products in harsh environments. MPCBFCs play a crucial role in the development and production of electronics for military equipment, including: Communication systems Radar and sonar devices Read more…