PCBA

Why Do You Need Turnkey PCB Assembly Services?

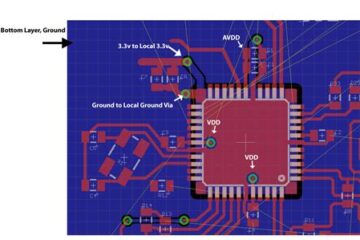

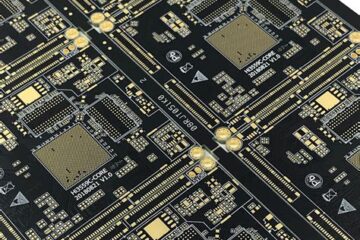

What is Turnkey PCB Assembly? Turnkey PCB Assembly is a comprehensive service provided by electronics manufacturing companies that encompasses the entire process of producing printed circuit boards (PCBs), from design to final assembly. This service includes PCB design, component sourcing, PCB fabrication, component placement, soldering, testing, and quality control. The Turnkey PCB Assembly Process The turnkey PCB assembly process typically involves the following steps: PCB Design: The process begins with the creation of a PCB Read more…