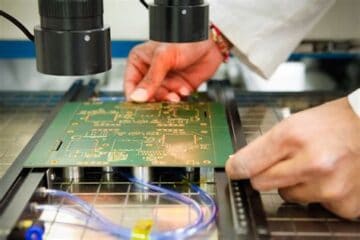

PCBA

CEM-3 PCB Manufacturers

Introduction to CEM-3 PCB CEM-3 (Composite Epoxy Material-3) is a high-quality, flame-retardant printed circuit board (PCB) substrate material that is widely used in the electronics industry. It is known for its excellent mechanical and electrical properties, making it an ideal choice for a wide range of applications, including consumer electronics, industrial control systems, and telecommunications equipment. Composition and Properties of CEM-3 CEM-3 is a composite material that consists of a woven fiberglass cloth impregnated with Read more…