PCBA

The Complete Guide on Aerospace Electronics PCB Assembly & Design

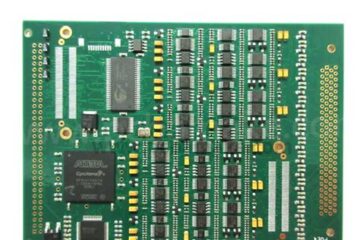

Introduction to Aerospace PCBs Printed Circuit Boards (PCBs) are the backbone of modern electronics, and this is especially true in the aerospace industry. Aerospace PCBs are designed to withstand extreme conditions such as high temperatures, vibrations, and radiation while maintaining reliable performance. These PCBs are critical components in various aerospace applications, including satellites, aircraft, and spacecraft. In this comprehensive guide, we will delve into the world of aerospace PCB assembly and design, covering essential aspects Read more…