PCBA

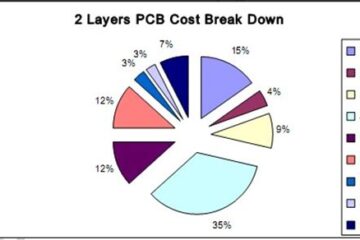

Some of the biggest influences that affect PCB Manufacturing Cost

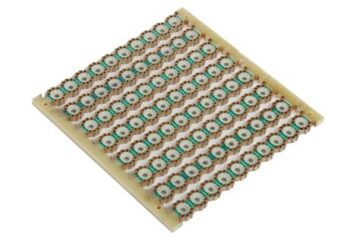

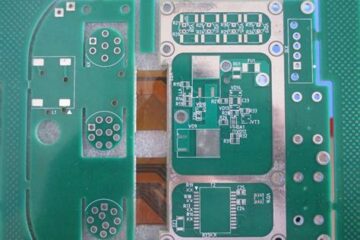

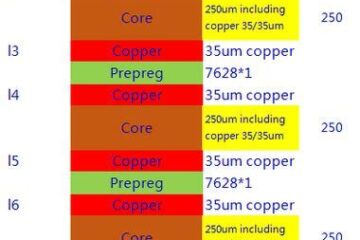

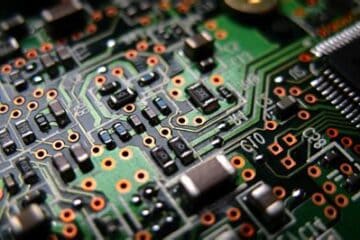

Board Size and Complexity The size and complexity of a PCB are among the most significant factors that influence its manufacturing cost. Larger boards require more material, which increases the overall cost. Additionally, complex designs with intricate routing, multiple layers, and high component density are more challenging to manufacture and therefore more expensive. Board Size Relative Cost Small Low Medium Moderate Large High Number of Layers The number of layers in a PCB also plays Read more…