PCBA

Simple Ways To Reduce PCB Assembly Cost

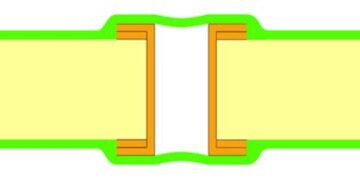

Optimize PCB Design for Manufacturing One of the most effective ways to reduce PCB assembly cost is by designing your boards with manufacturing in mind from the start. This approach, known as Design for Manufacturing (DFM), involves making design choices that simplify the assembly process and minimize the potential for errors or defects. Keep the Board Size Small Smaller PCBs require less material, are faster to assemble, and can often be panelized more efficiently, leading Read more…