PCBA

RIGID PRINTED CIRCUIT BOARDS

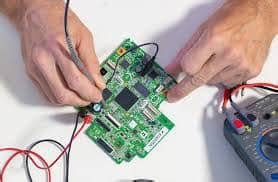

What are Rigid PCBs? Rigid PCBs are a type of printed circuit board characterized by their solid, inflexible substrate material. These boards are typically made from a combination of fiberglass and epoxy resin, which provides excellent mechanical stability and electrical insulation. The conductive traces and pads on rigid PCBs are usually made of copper, allowing for the efficient transfer of electrical signals between components. Advantages of Rigid PCBs Rigid PCBs offer several advantages over other Read more…