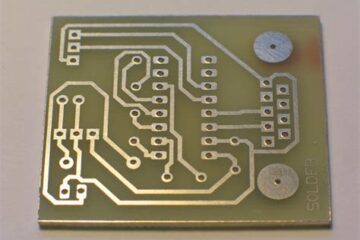

PCBA

Recent and Rising Application of Industrial Automation

Robotics and Advanced Manufacturing One of the most prominent areas of growth for industrial automation is in robotics and advanced manufacturing. Robots are becoming increasingly sophisticated, with improved dexterity, precision, and the ability to work collaboratively with humans. This has led to their widespread adoption in industries such as automotive, electronics, and aerospace. Collaborative Robots (Cobots) Collaborative robots, or cobots, are designed to work safely alongside human workers, taking on repetitive or dangerous tasks while Read more…