PCBA

6 Layers PCB Manufacturers

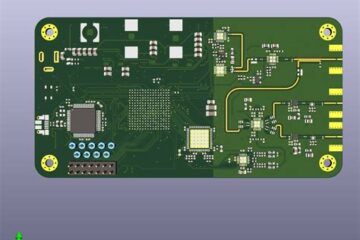

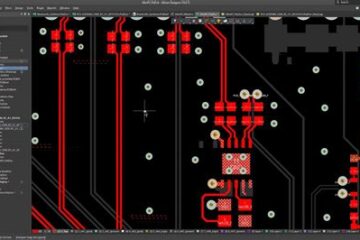

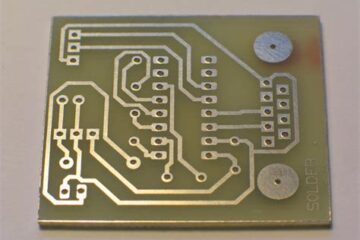

Introduction to 6 Layers PCB A 6 layers PCB, also known as a multilayer PCB, is a printed circuit board that consists of six conductive copper layers laminated together with insulating material. These layers are interconnected through plated holes called vias, which allow electrical signals to pass between the layers. The use of multiple layers enables more complex circuits to be designed in a smaller footprint, making 6 layers PCBs ideal for high-density applications such Read more…