PCBA

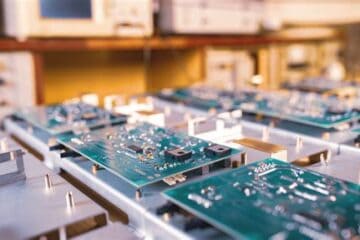

PCB MANUFACTURER OF RENEWABLE ENERGY ELECTRONICS

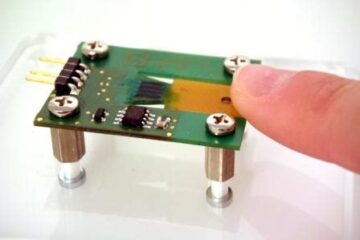

Introduction to PCBs in Renewable Energy Printed circuit boards (PCBs) play a critical role in the rapidly growing renewable energy industry. PCBs are found in a wide range of renewable energy devices and systems, including: – Solar panels and solar power inverters – Wind turbine control systems – Hydroelectric generators – Geothermal heat pumps – Biofuel processing equipment PCBs help enable the efficient generation, conversion, storage, and distribution of clean, sustainable energy from renewable sources. Read more…